Air filter chamber

A filter chamber and air technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inconvenient installation and transportation of air filters, achieve optimal maintenance effect, convenient disassembly, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

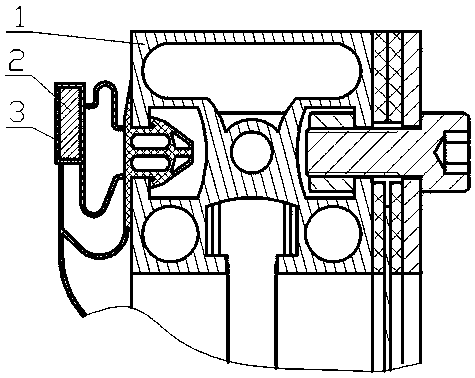

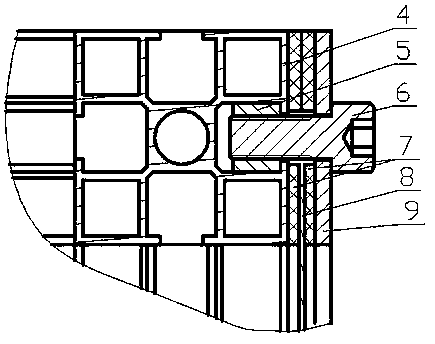

[0020] see Figure 1-Figure 3 , an air filter chamber, which is composed of a filter chamber frame, a door body sealing structure, an intake pipe clamp structure, a filter screen and a filter screen sealing structure; the filter chamber frame is an aluminum profile 1 overlapping frame, and the frames are connected by screws; The door body sealing structure is used for the connection between the inspection door of the air filter chamber and the frame of the filter chamber; the intake pipe clip structure is used for the connection of the intake pipe of the turbocharger equipment, and is used to adjust the position of the outlet of the air filter chamber. The outlet position of the chamber matches the position of the intake pipe of the turbocharger equipment to realize the connection between the outlet of the air filter chamber and the intake pipe of the turbocharger equipment; the filter screen 8 cooperates with the filter screen sealing structure to realize the sealing of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wind resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com