High and low temperature thermal-humidity test chamber

A damp heat test, high and low temperature technology, applied in the field of test chambers, can solve problems such as the inability to effectively ensure the uniformity of temperature and humidity inside the test chamber, affecting the accuracy of test results, and inconvenient use, saving debugging time and reducing production. Cost and post-maintenance cost, the effect of convenient disassembly and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings of the description.

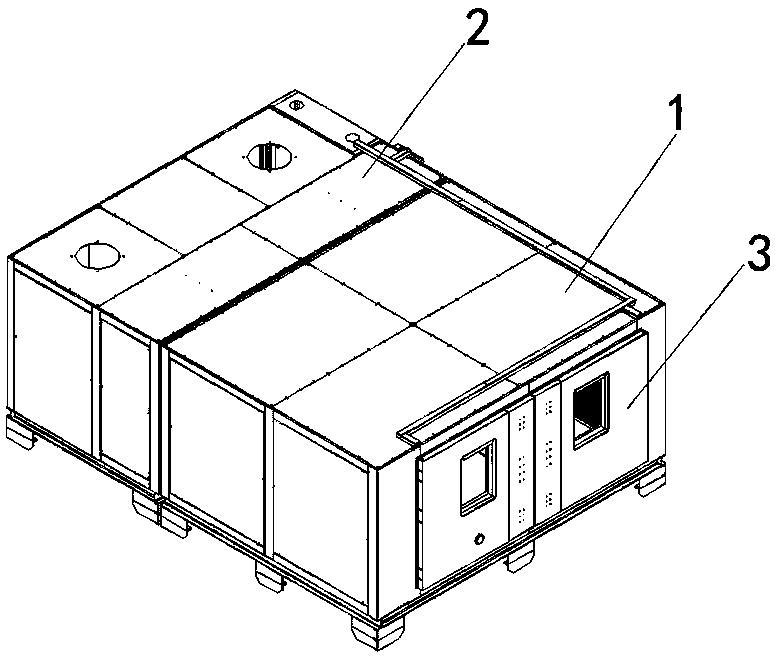

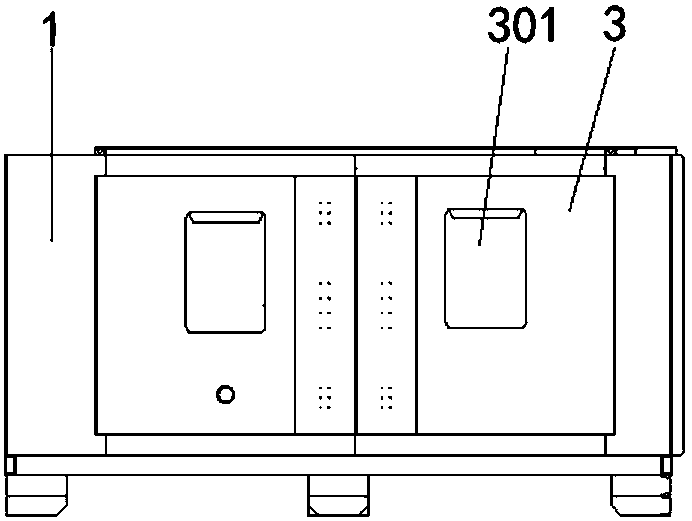

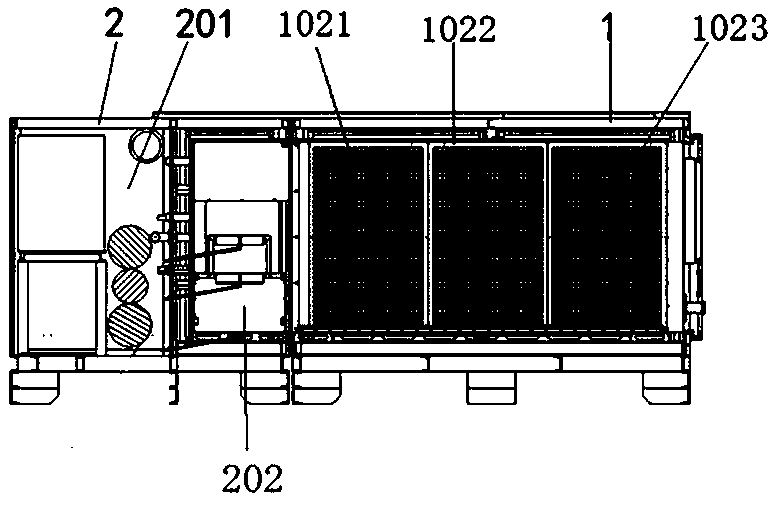

[0036] Such as figure 1As shown, a high and low temperature damp heat test chamber includes a test chamber module 1, an electrical cabinet module 2 and a refrigeration system. The body modules 2 are connected by quick connection buckles. After the two modules are debugged in the factory, they can be divided into two modules and transported to the customer's site. Then, the two modules can be connected into a whole through a quick connection buckle, and normal detection can be carried out, which can be easily disassembled and assembled. Maintenance saves the debugging time during installation and greatly reduces the production cost and later maintenance cost of the test chamber. The shells of the two modules are of double-layer insulation structure. The double-layer insulation structure includes reinforced and thickened steel plates on the outside a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com