Special water paint bottom-surface double-head double-side roller coating equipment

A water-based paint and bottom surface technology, which is applied to the surface coating liquid device, coating, pre-treatment surface, etc., can solve the problems of inability to complete rapid dehumidification, curing, and water-based paint roll coating in one go, and achieve Easy dehumidification and curing treatment, easy to apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

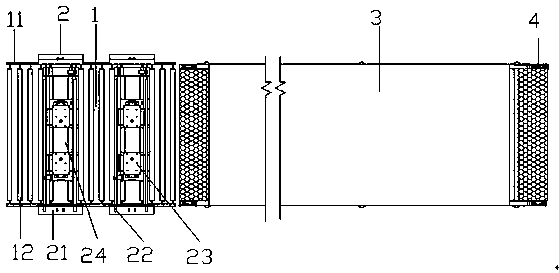

[0022] refer to figure 1 , in the embodiment of the present invention, a double-headed double-sided roll coating equipment for special water-based paint bottom surface, including a conveying device 1, the conveying device 1 is connected with a frame 11 and a conveying roller 12, and the connecting frame 11 is provided with a conveying Roller 12, which can effectively facilitate the transportation of articles, thereby facilitating the work of the equipment. Roller coating devices 2 are installed on the left and right ends of the upper side of the conveying device 1, and two roller coating devices 2 are set on the conveying device 1. Can effectively carry out coherent smear to article like this, can conveniently smear primer like this, described roller coating device 2 comprises mounting plate 21, connecting rod 22, connecting frame 23 and smearing roller 24, described mounting plate 21 It is arranged on the front end of the upper side of the connecting frame 11, which can facil...

Embodiment 2

[0024] The difference from Embodiment 1 is that the four corners on the upper side of the high-temperature dehumidification drying tunnel 3 are provided with connecting rings 4, and the connecting ring 4 is installed and fixed with the high-temperature dehumidifying drying tunnel 3 through mounting blocks and mounting bolts, which can effectively facilitate Installation and connection of equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com