Ampoule wax sealing device convenient to operate

A technology of ampoules and wax liquid, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc., which can solve the problems of inconvenient portability, complex structure, and large volume of the capping machine, and achieve the advantages of easy portability, improved operation efficiency, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

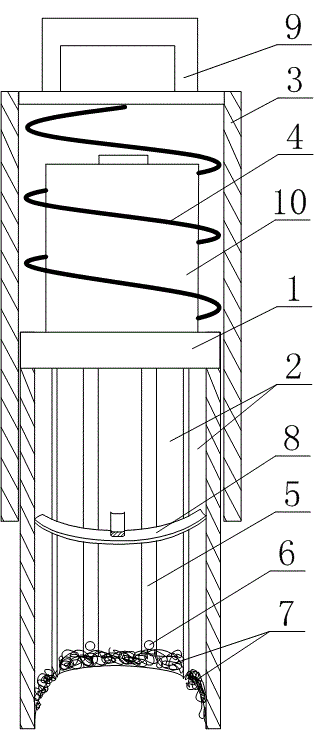

[0022] Easy-to-handle ampoule sealing devices such as figure 1 As shown, it includes a support 1, a latch 2 arranged around the support 1 in a circular shape and the top end is fixed to the support 1, a clasp 3 arranged above the support 1 for closing the latches, and a snap ring 3 arranged on the support 1 1 and the return spring 4 between the clasp 3; the wax liquid storage tank 5 is vertically arranged on the said clamp tooth 2, and the wax liquid outlet 6 is arranged at the bottom of the wax liquid storage tank 5, and the wax liquid at the bottom of the clamp tooth 2 A high temperature resistant fiber 7 is also provided at the position of the liquid outlet 6 .

[0023] In the present invention, the number of the locking teeth 2 is more than two, and the shape of the locking teeth is the same as that of the bottle cap, so that the aluminum foil cover can be effectively pressed and fixed on the bottle cap. In the present invention, the number of the locking teeth 2 is prefe...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that the structure of the clasp 3 is optimized in this embodiment, that is, a handle 9 is provided above the clasp 3 . The latch 2 is made of stainless steel.

Embodiment 3

[0027] The difference between this embodiment and embodiment 1 or embodiment 2 is that the latch 2 in this embodiment is made of stainless steel.

[0028] And in order to achieve the effect of complete sealing by one operation, the locking teeth 2 are provided with inner bumps. At the same time, in order to better realize the operation of installing the aluminum foil on the cover during operation, the snap ring 3 is provided with protrusions that are arranged in the same direction as the snap ring 3 and the corresponding position of the snap ring 2 is set There are grooves to match the lugs. During operation, the snap ring 3 only needs to be rotated, and the snap ring 3 drives the snap teeth 2 to rotate, thereby achieving the effect of evenly applying the wax liquid to the sealing position of the ampoule through the high temperature resistant fiber 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com