Thread-rolling machine capable of preventing sweeps from leaving on thread-rolling plates

The technology of thread rolling plate and thread rolling machine is applied in the field of thread rolling machine, which can solve the problems of insufficient smoothness of screw teeth, reduce bolt quality, screw influence, etc., and achieve the effect of avoiding secondary influence and improving product production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

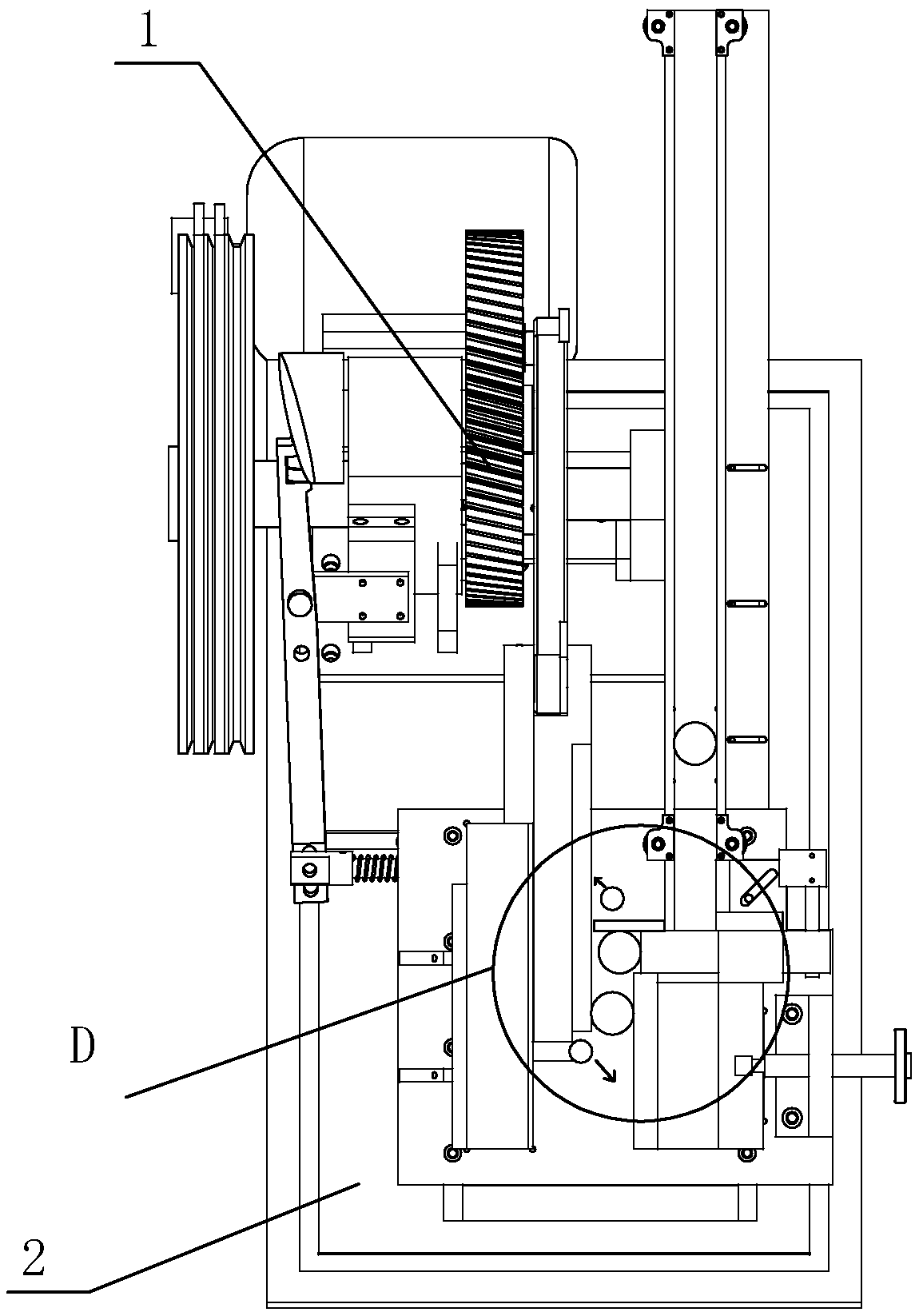

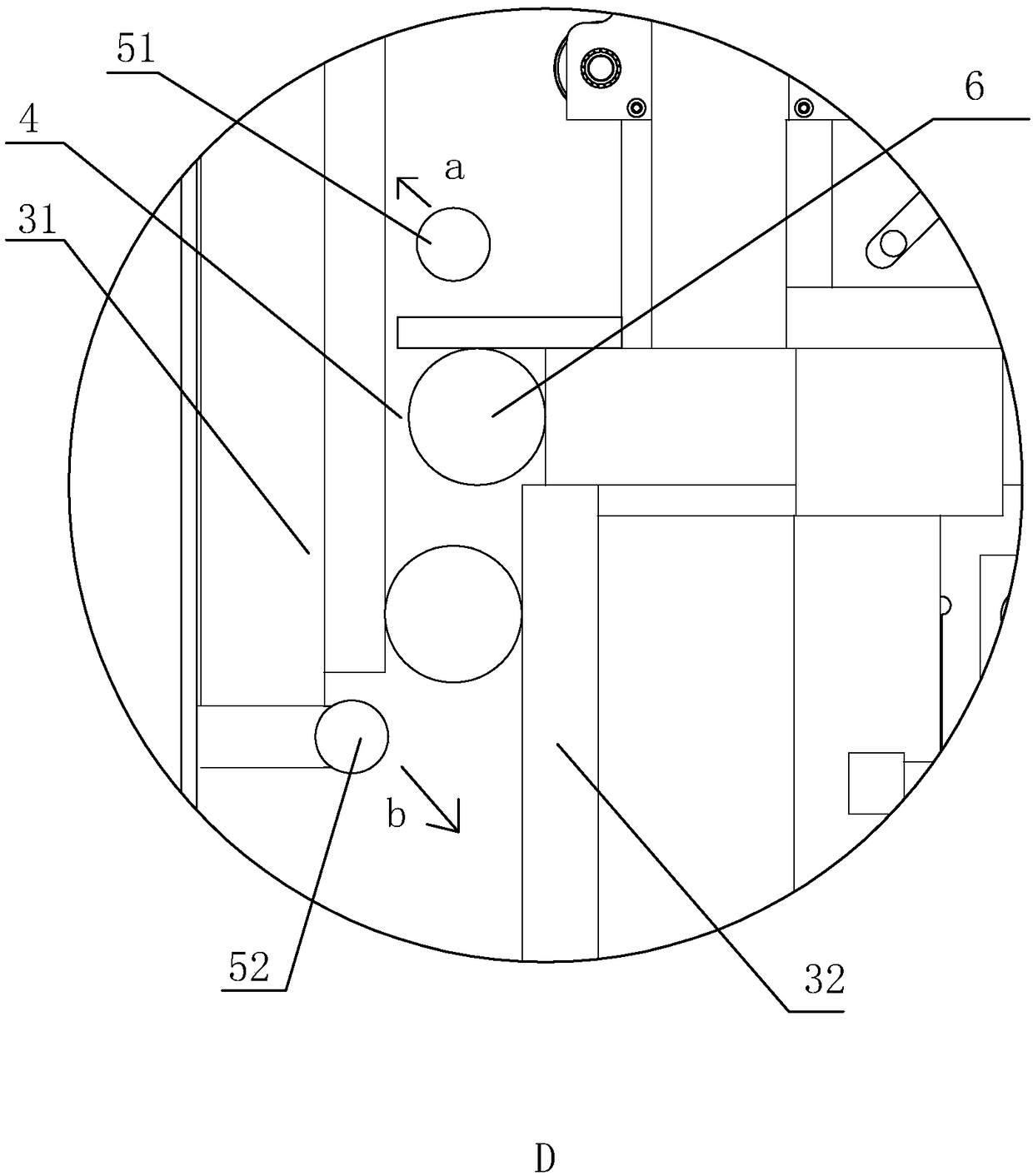

[0011] refer to figure 1 and figure 2 The embodiment of the thread rolling machine of the present invention that prevents waste from the thread rolling plate will be further described.

[0012] A thread-rolling machine for preventing waste left over by the thread-rolling plate, comprising a frame 2, on which a thread-rolling plate is arranged, and the thread-rolling plate includes a fixed plate 32 and a moving plate 31, and the two ends of the fixed plate 32 are respectively It is the inlet 4 and the outlet of the screw, the first chip removal nozzle 51 is provided on the frame 2 corresponding to the inlet 4, and the second chip removal nozzle 52 is arranged on the end of the moving plate 31 corresponding to the outlet. The axis of the first chip removal nozzle 51 and the second chip removal nozzle 52 is the same as the axis of the screw, and the first chip removal nozzle 51 and the second chip removal nozzle 52 are all provided with nozzles. The spout of the chip removal n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com