Full-automatic replacement device for polishing brushes

A technology of polishing device and polishing brush, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, and parts of grinding machine tools, etc., which can solve the problems of restraining automation, reducing production efficiency, and increasing labor costs, so as to reduce manpower and material resources , The effect of increasing the storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, this equipment can be designed as a polishing machine for fully automatic replacement of polishing brushes with a chassis and a self-circulating adsorption device. The specific implementation methods are as follows:

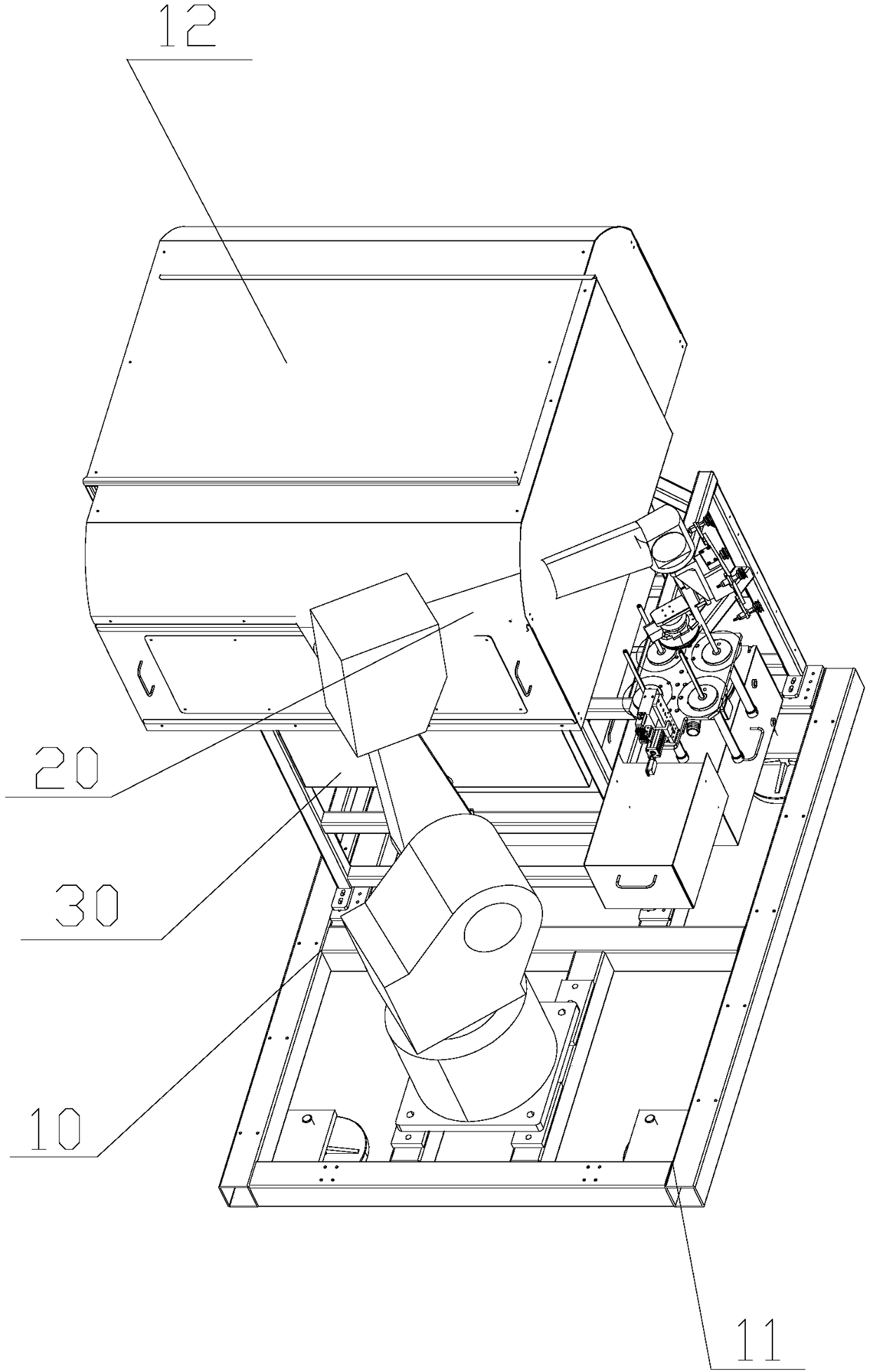

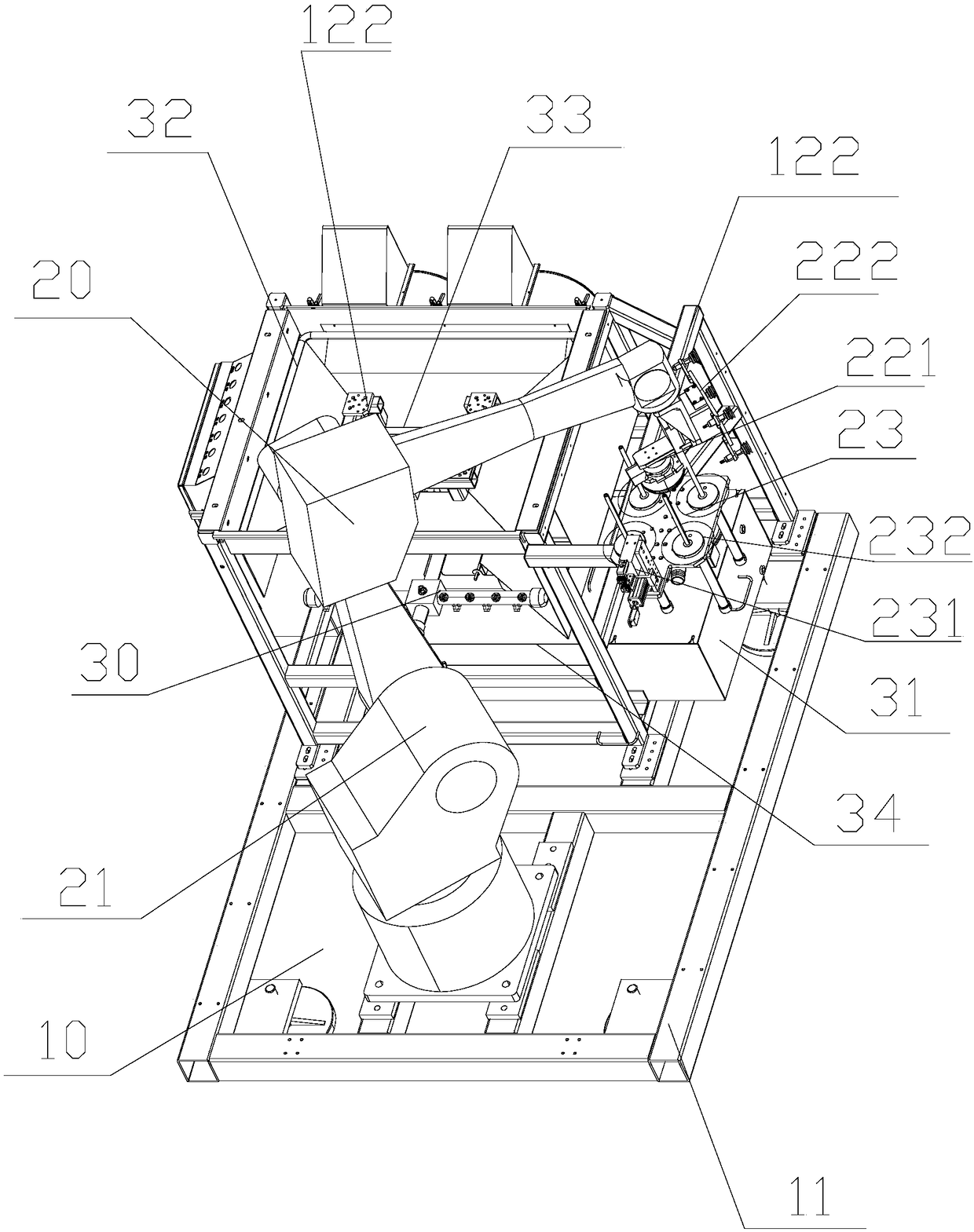

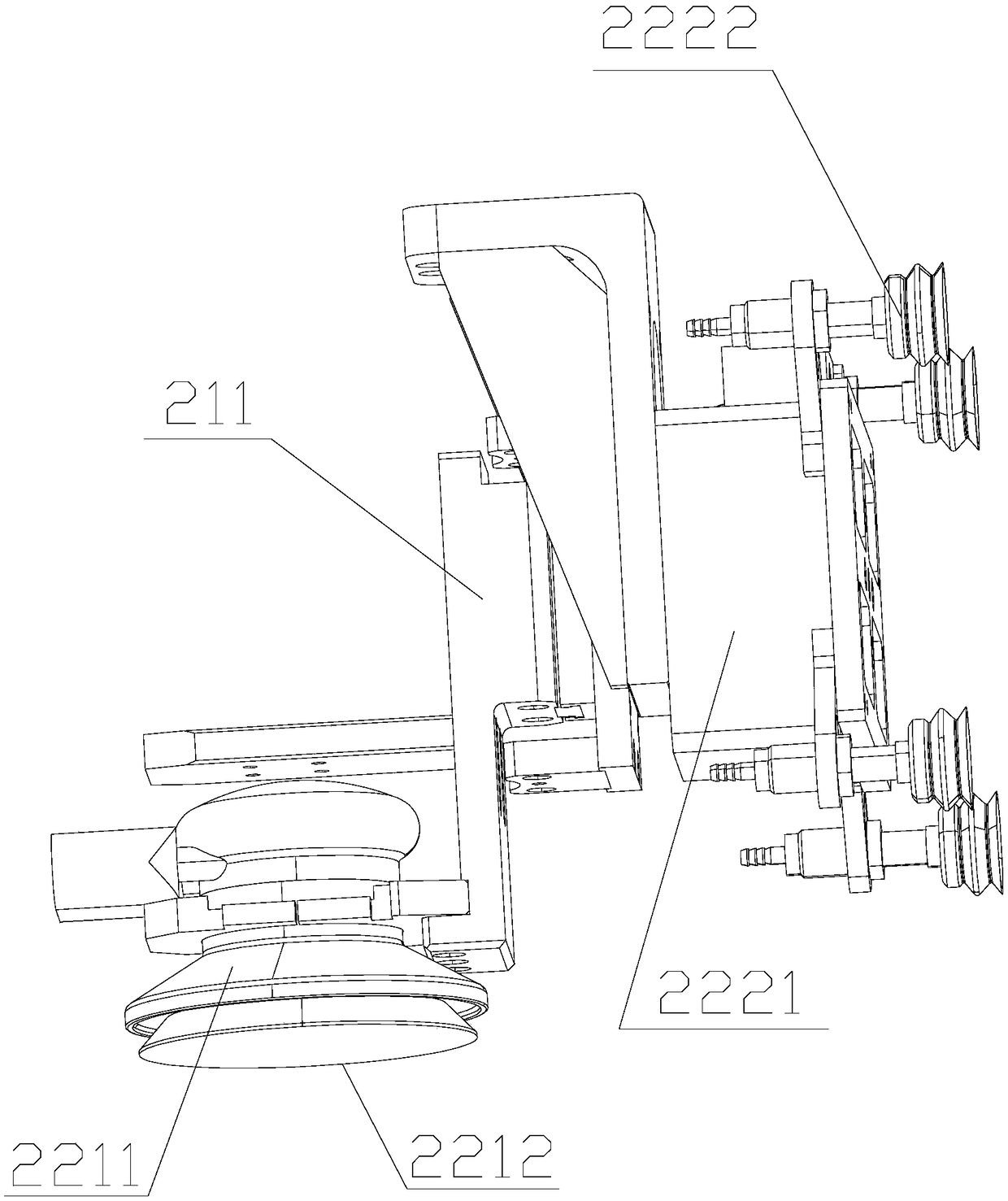

[0022] Such as figure 1 as well as figure 2 As shown, it includes a frame 10, a polishing machine 20 and a self-circulating adsorption device 30. The frame 10 includes a base 11 and a cabinet 12. A workpiece polishing position 121 is arranged in the cabinet 12. The front end of the cabinet 12 is The automatic induction door can automatically sense the action of the polishing machine 20. When the polishing machine 20 comes to polish the workpiece, the induction door can be opened automatically, so that the front end of the chassis 12 is not blocked, which is convenient for the polishing machine 20 to polish. When the polishing machine 20 operates When leaving, the induction door can be closed automatically. The self-circulation adsorption de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com