Intelligent wearable face shell and manufacturing method thereof

A technology of smart wear and production method, which is applied to the field of smart wearable face case and its production, and can solve problems such as window deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

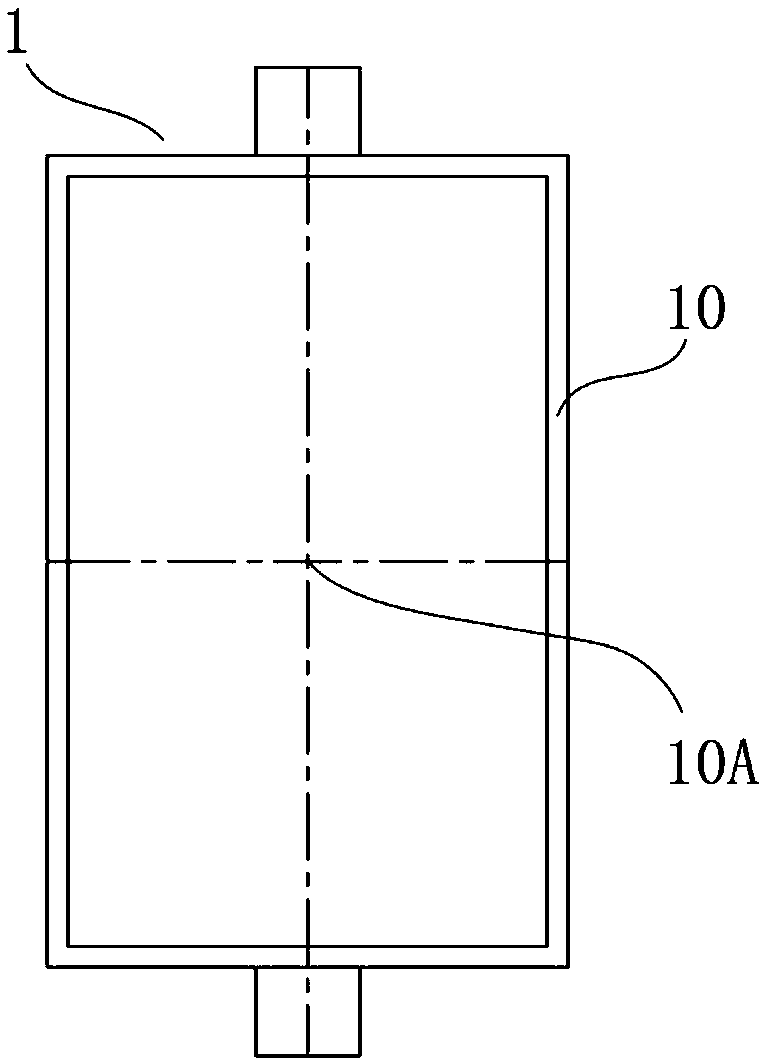

[0023] refer to Figure 1 to Figure 4 , the embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

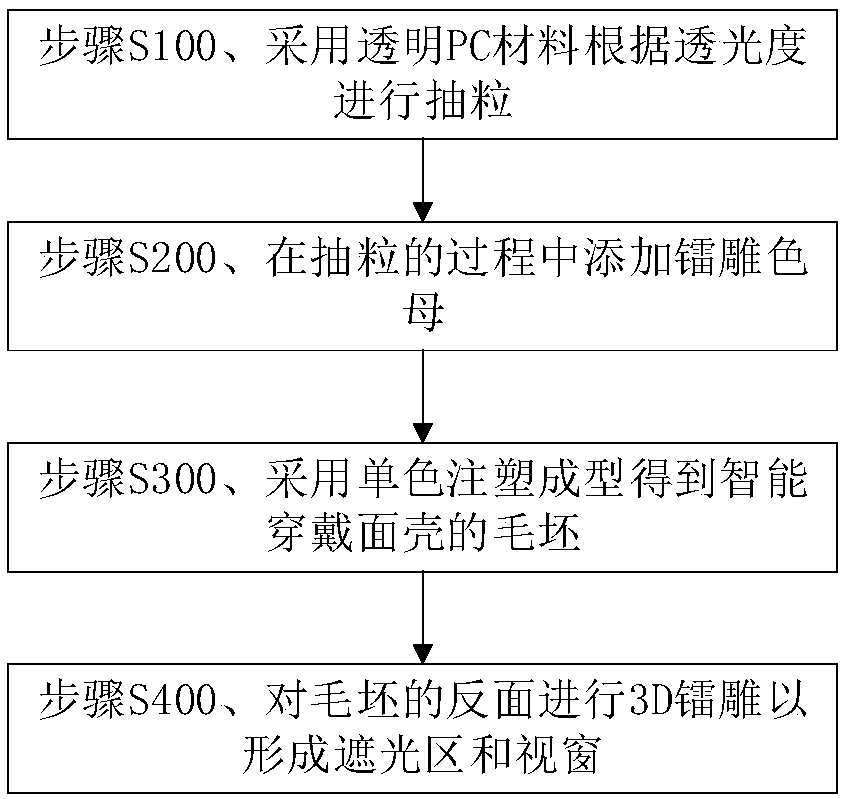

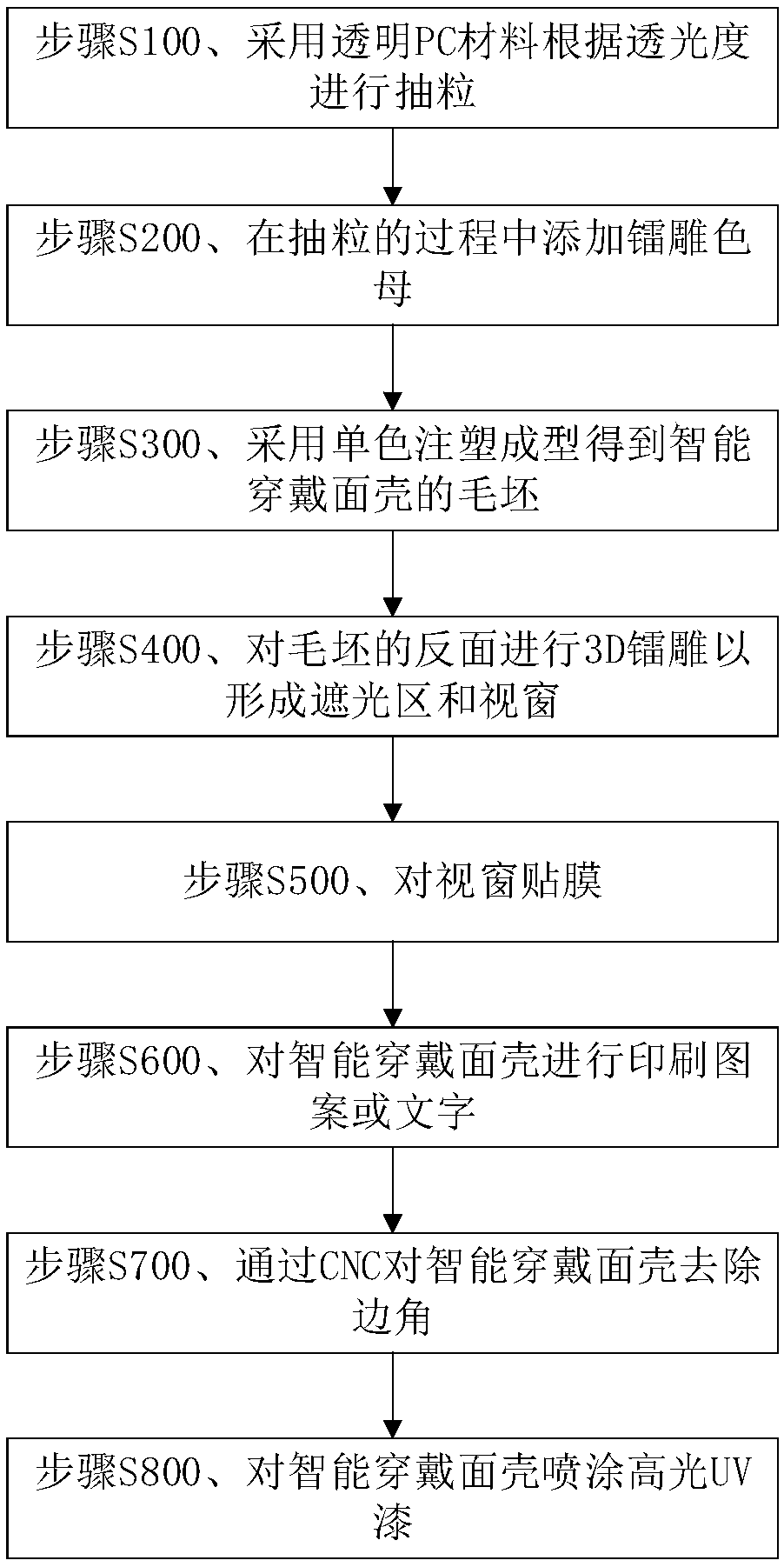

[0024] The smart wearable device of the present invention includes a watch, a wristband, a finger ring, etc., and the smart wearable cover refers to the display shell of the above smart wearable device. refer to figure 1 , The manufacturing method of the intelligent wearable face shell of the present invention includes step S100 to step S400.

[0025] Step S100, use transparent PC material to pump particles according to the light transmittance. Transparent PC material is most suitable for laser engraving and can achieve a high yield rate. Different products have different light transmittances, such as 90%, 80%, 70%, and 60% light transmittance. According to these light transmittances, use granulation equipment to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com