Silk screen printing screen frame system capable of being rapidly positioned

A technology of screen printing and screen frame, which is applied to screen printing machines, printing machines, printing machines, etc. It can solve the problems of poor calibration accuracy and long calibration time, and achieve the effects of fast calibration, short calibration time and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

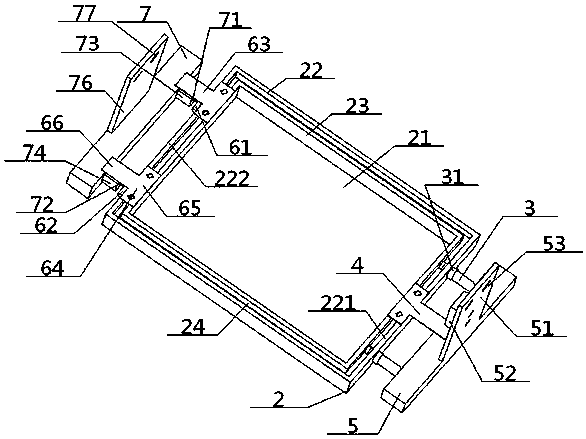

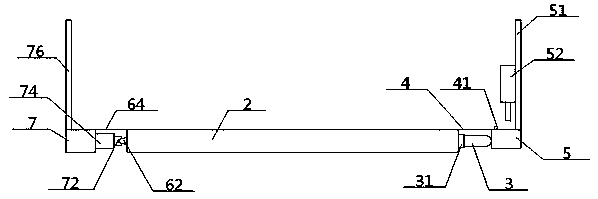

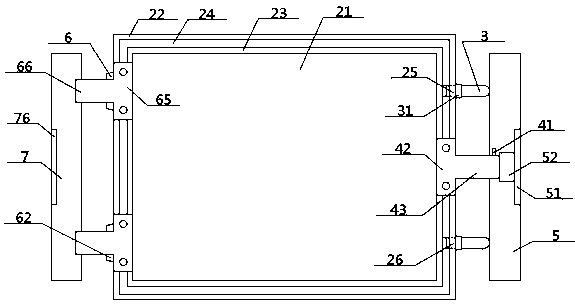

[0045] see Figure 1 to Figure 6 , a screen printing screen frame system that can be quickly positioned, including a screen frame 2 for screen printing; A concentric outer frame 22 is sleeved, and the bottom surfaces of the outer frame 22 and the inner frame 23 are all connected with the top surface of the frame bottom surface 21, and a concentric inter-frame groove 24 is sandwiched between the outer frame 22 and the inner frame 23, and the outer frame 22 Open the upper screw hole 25, the lower screw hole 26 on the right frame bar 221 of the upper screw hole 25, and the lower screw hole 26 is respectively provided with a distance-adjusting screw 3, and the inner end of the distance-adjusting screw 3 extends to the groove 24 between the frames Inside, the outer end of the pitch-adjusting screw 3 passes through the upper screw hole 25 or the lower screw hole 26 and extends to the outside of the outer frame 22, and the pitch-adjusting screw 3 is provided with a pitch-adjusting nu...

Embodiment 2

[0047] Basic content is the same as embodiment 1, the difference is:

[0048] The top surface of the right fixed plate 5 is vertically connected with the bottom edge of the right vertical plate 51, and the inner side of the right vertical plate 51 is provided with a downward pressure cylinder 52, and the output end of the downward pressure cylinder 52 is located at the top of the right fixed plate 5. Directly above the surface, the projection of the output end of the downward pressure cylinder 52 on the top surface of the right fixed plate 5 intersects with the horizontal extension line of the positioning plate 4 outer ends. The positioning plate 4 is a T-shaped structure, including positioning vertical bars 42 and positioning horizontal bars 43, the bottom surface of the positioning vertical bars 42 is connected with the top surface of the screen frame 2, and the right side of the positioning vertical bars 42 is connected with the positioning horizontal bar. The inner end of ...

Embodiment 3

[0050] Basic content is the same as embodiment 1, the difference is:

[0051] The left fixing part 6 includes an upper left inserting block 61 and a lower left inserting block 62 arranged up and down along the left frame bar 222, and an upper left groove 71 and a lower left groove 72 arranged up and down are arranged on the inner surface of the left fixing plate 7. To carry out the corresponding insertion fit with the upper left inserting block 61 and the lower left inserting block 62 . The inner surface of the left fixed plate 7 is connected with the inner ends of the upper left telescopic part 73 and the lower left telescopic part 74, the outer end of the upper left telescopic part 73 is connected with the left side part of the upper left groove 71, and the outer part of the lower left telescopic part 74 The end is connected with the left side of the lower left groove 72, and the upper left groove 71 and the right side of the lower left groove 72 are provided with notches 75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com