Automatic assembling and disassembling system for flower pot module in vertical greening operation

A technology of vertical greening and automatic loading and unloading, which is applied in the field of vertical greening, can solve problems such as the far-reaching difference between operating efficiency and safety, and slow technological progress, and achieve the effect of avoiding unsafety, heavy load, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

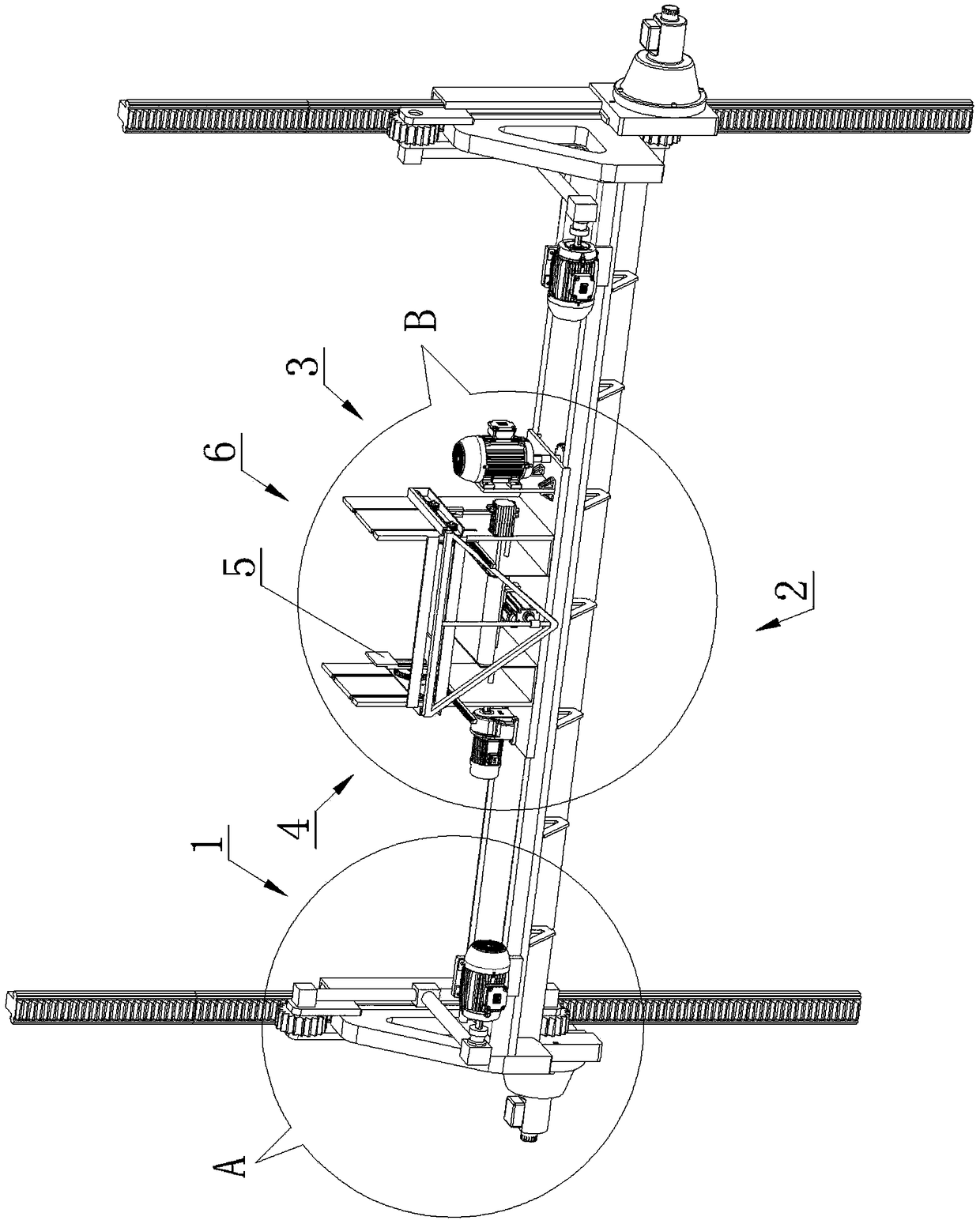

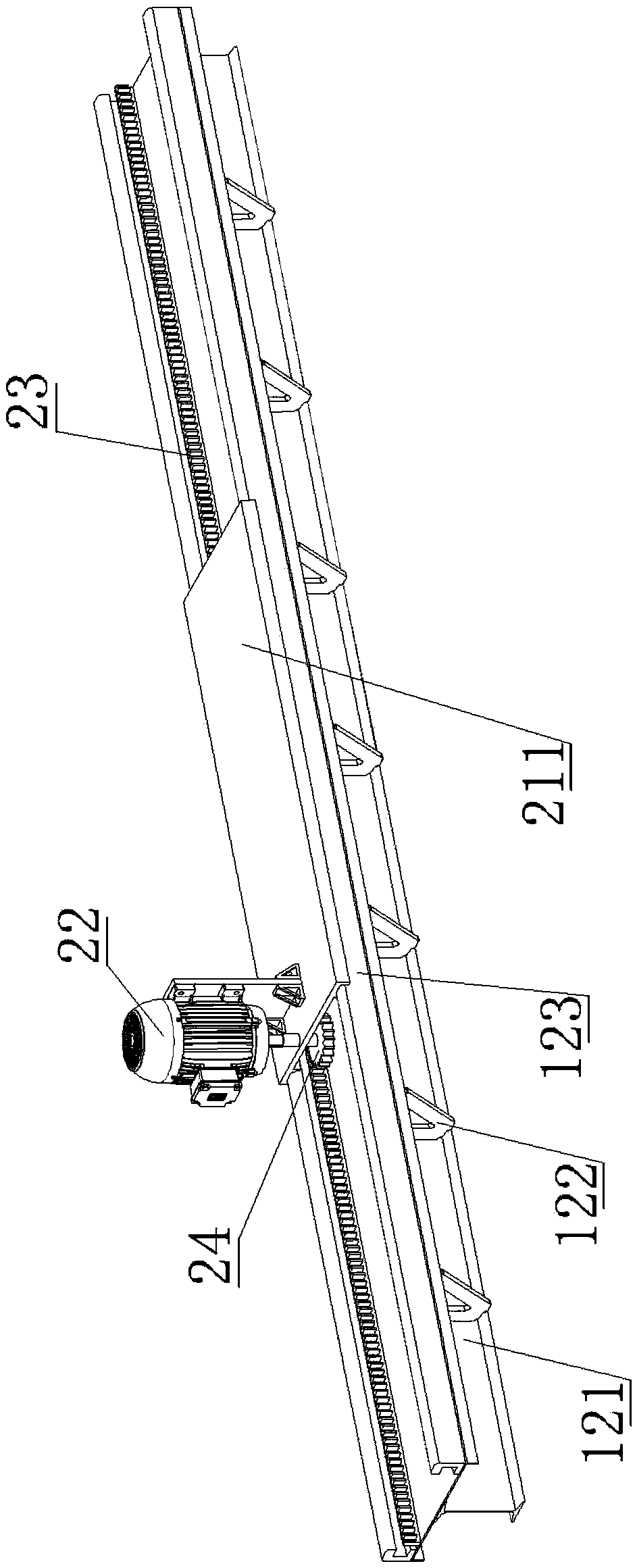

[0034] from Figure 1 to Figure 6 It can be seen that the automatic loading and unloading system for flowerpot modules in vertical greening operations of the present invention includes a lifting device 1, a translation device 2, a lifting device 3, a telescopic propulsion device 4 and a flowerpot seat for placing flowerpot modules 5, of which,

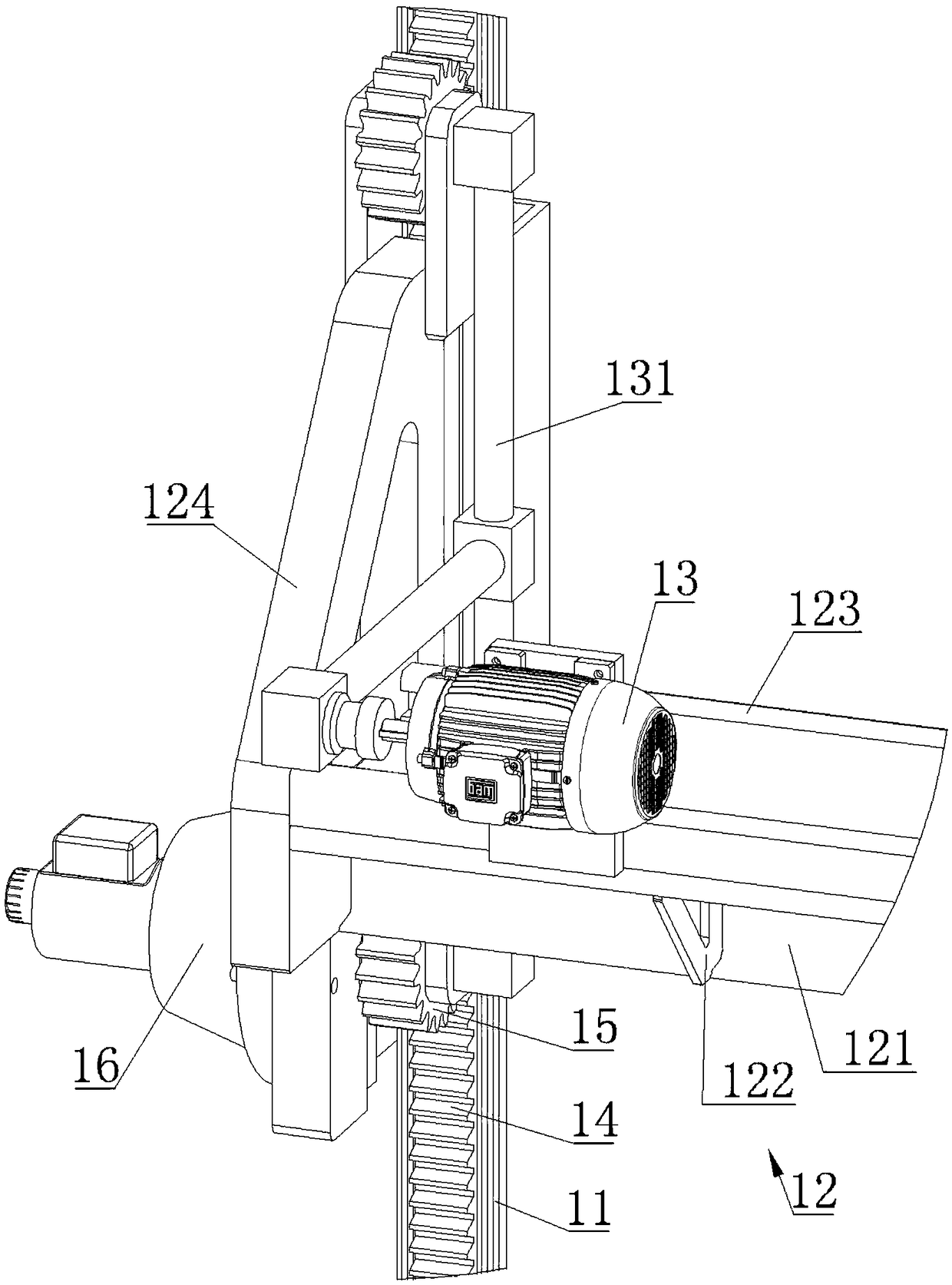

[0035] Elevating device 1 comprises column 11, lifting table 12, lifting motor 13, tooth bar 14, gear 15 and anti-falling safety device 16, and column 11 has two and is installed on the metope of high-rise outer wall parallel to each other, and the transverse of column The section is inverted T-shaped,

[0036]Lifting table 12 comprises I-beam 121, triangular stiffener plate 122, horizontal travel axis 123, triangular support 124 and some fastening wheels 125, and triangular stiffener 122 is evenly welded on the front and rear sides of I-beam 121 bottom, and I-beam 121 Form the bottom support member of the whole lifting device 1 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com