Air conditioner oil return control method and device and air conditioner

A technology of oil return control and air conditioner, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increased power consumption, performance waste, and reduced energy efficiency of unit operation, and achieve the effect of improving energy efficiency in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

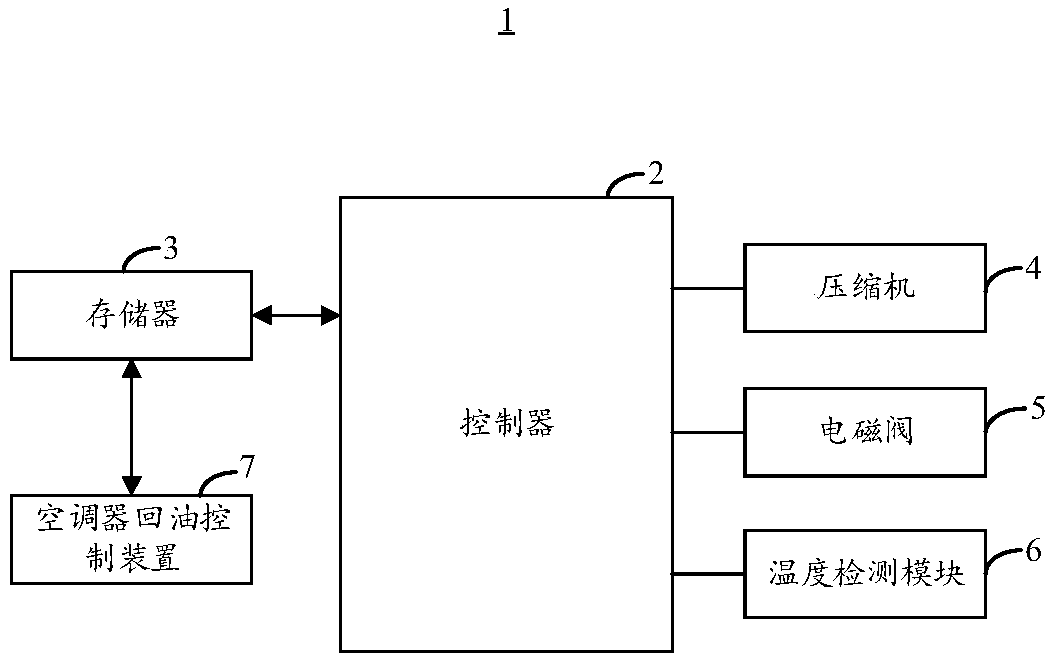

[0043] The embodiment of the present invention provides an air conditioner 1, which is used to adjust the indoor temperature, reduce the energy consumption of operation, and improve the efficiency. see figure 1 , is a functional block diagram of the air conditioner 1 provided by the embodiment of the present invention. The air conditioner 1 includes: a memory 3 , a controller 2 , a compressor 4 , a solenoid valve 5 , an oil return capillary, an oil separator, a temperature detection module 6 and an air conditioner oil return control device 7 . Wherein, the controller 2 is electrically connected with the memory 3, the temperature detection module 6, the compressor 4 and the solenoid valve 5, the oil return capillary is communicated with the oil separator through the solenoid valve 5, and the air conditioner oil return control device 7 includes at least one It may be stored in the memory 3 in the form of software or firmware.

[0044] The memory 3 can be used to store software...

no. 2 example

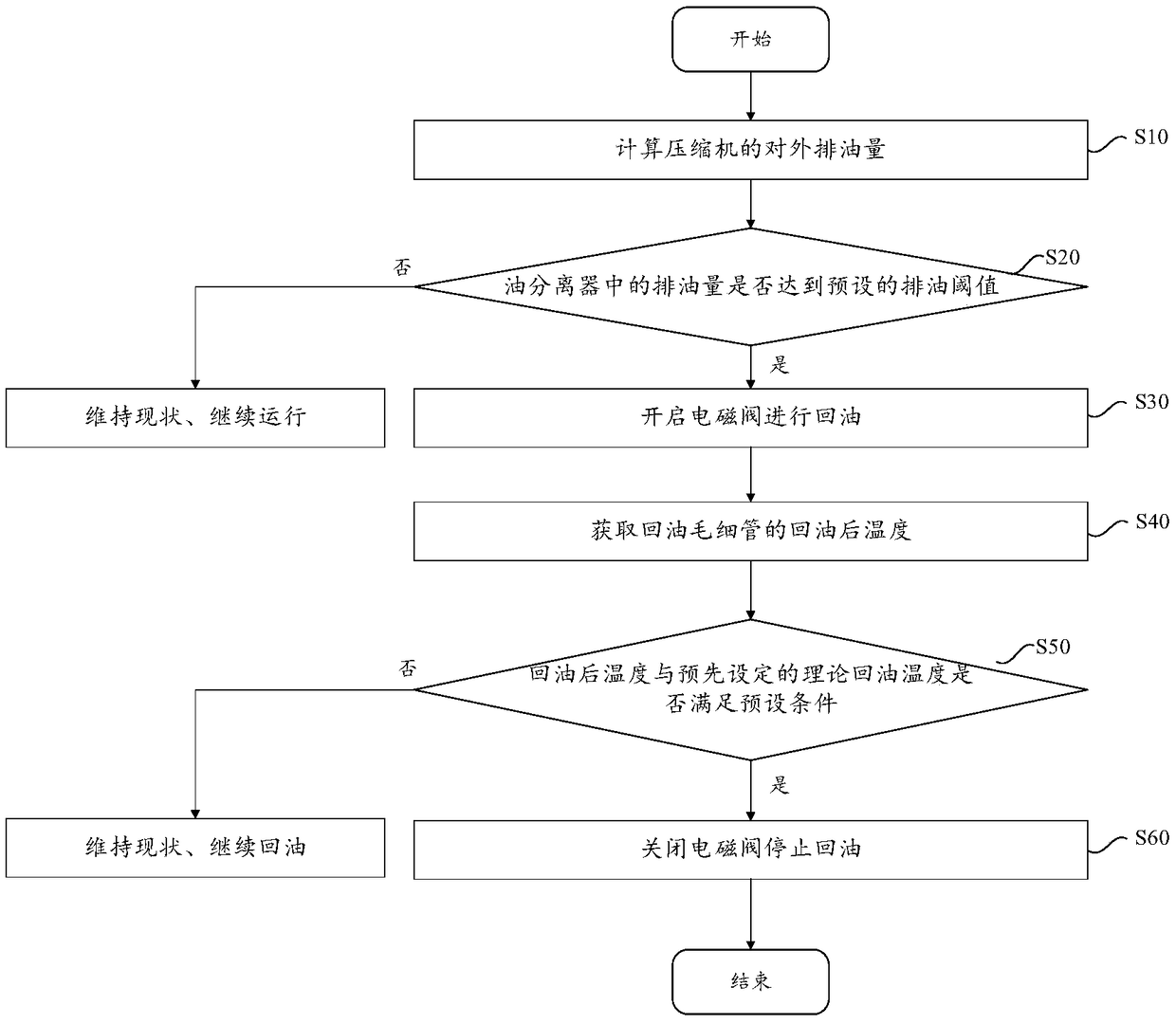

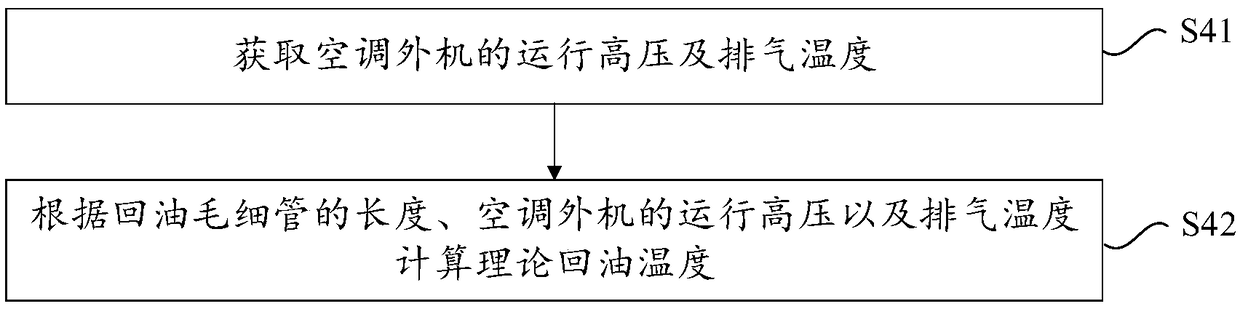

[0050] This embodiment provides a method for controlling the oil return of an air conditioner, which is used to control the oil return of the oil separator, so as to prevent the refrigerant from returning to the compressor 4 through the oil return capillary, resulting in waste of performance and increased power consumption. see figure 2 , figure 2 A schematic diagram of a method for controlling oil return of an air conditioner provided in this embodiment is shown, and the method for controlling oil return of an air conditioner includes the following steps: S10-S60.

[0051] Step S10: Calculate the oil discharge amount of the compressor 4 to the outside.

[0052] The compressor 4 needs compressor oil to lubricate its various components during operation. During the operation of the system, the compressor oil will be discharged from the compressor 4 together with the refrigerant (refrigerant), for example, to an oil separator. The external oil discharge amount of the compress...

no. 3 example

[0073] see Figure 4 , Figure 4 An air conditioner oil return control device 7 provided in a preferred embodiment of the present invention. It should be noted that the basic principles and technical effects of the air conditioner oil return control device 7 provided in this embodiment are basically the same as the air conditioner oil return control method provided in the second embodiment above. For a brief description, this embodiment For the parts not mentioned in the example part, reference may be made to the corresponding content in the above-mentioned embodiments.

[0074] The air conditioner oil return control device 7 includes an oil discharge calculation unit 8 , a judging unit 9 , a start oil return unit 10 , a temperature acquisition unit 11 , a temperature calculation unit 12 and a stop oil return unit 13 .

[0075] Wherein, the oil discharge amount calculation unit 8 is used for according to the oil discharge rate of the compressor 4, the operation frequency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com