Contact rail detecting system and using method thereof

A detection system and contact rail technology, applied in measuring devices, instruments, etc., can solve problems such as reflection prone to distortion, unsuitable for functional verification of contact rail systems, etc., and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

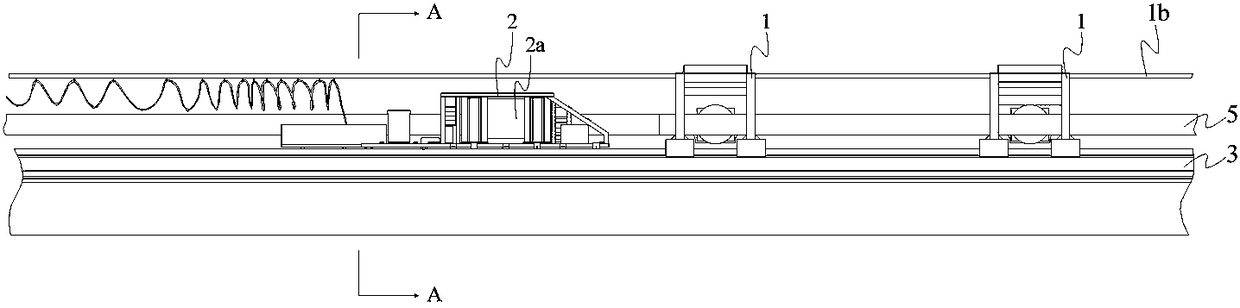

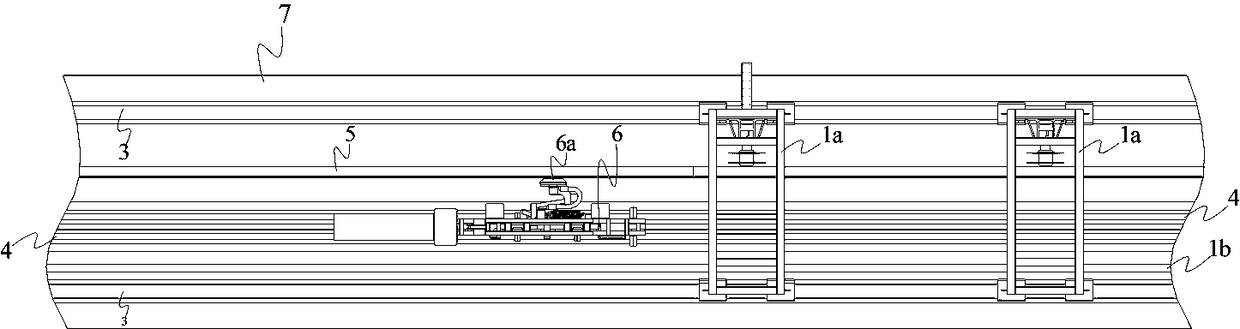

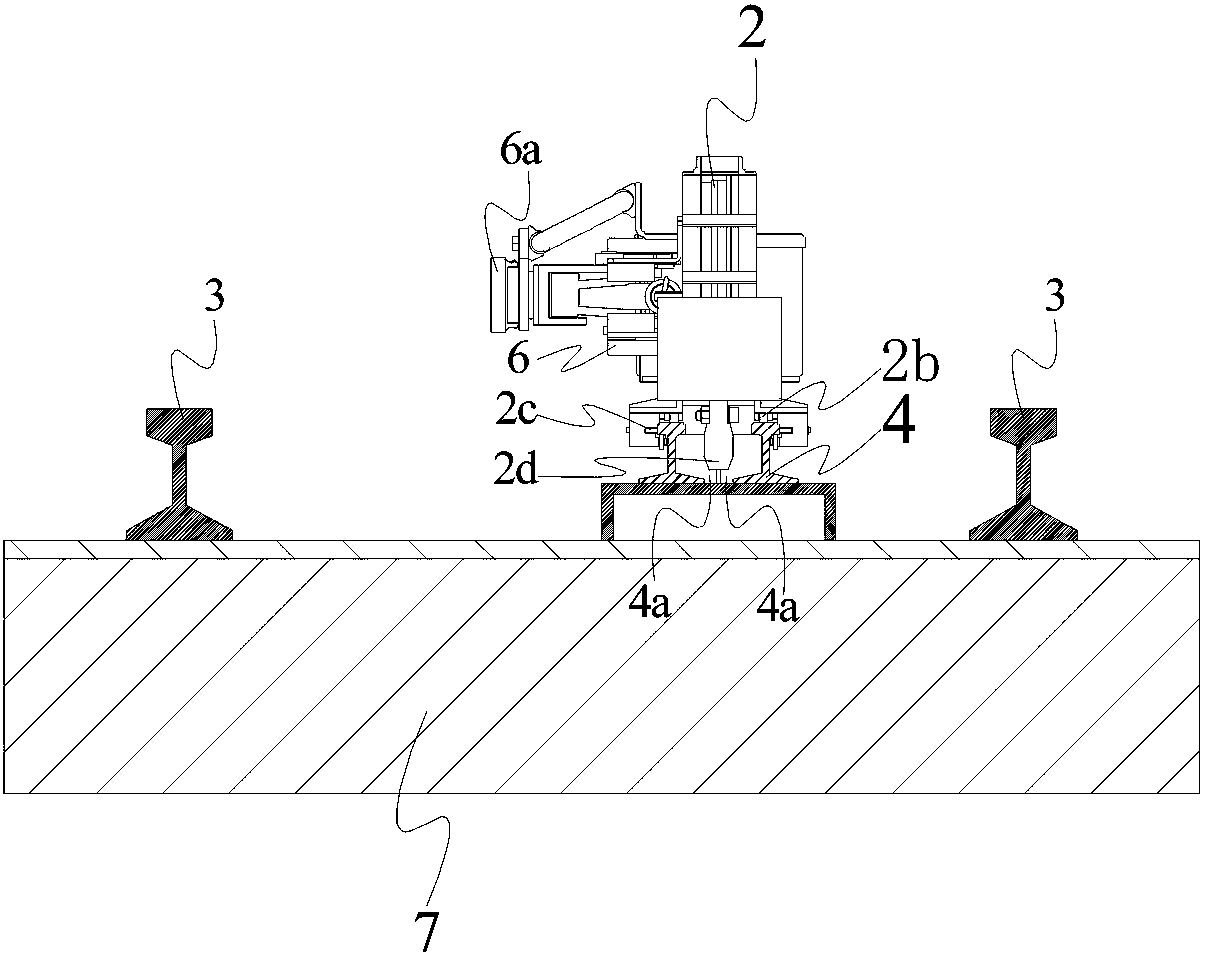

[0029] A contact rail detection system, the system includes a bracket module (1), a detection carrier (2), a launch module, an installation base (3), a running track (4), and a detection device; the contact rail is installed on the bracket module (1) , the bracket module (1) includes a bracket body (1a), a hanging wire bracket (1b); the sliding shoe device (6) is installed on the sliding shoe device installation position (2a) on the detection carrier (2), and the sliding shoe device (6) A current receiver or a device with some functions of the current receiver can be used; the detection carrier (2) is connected to the transmitter module, the bracket module (1) is installed on the installation base (3), and the installation base (3) is connected to the transmitter module. The running track (4) is fixed on the platform foundation (7), and the slider (6a) of the sliding shoe device (6) is positively pressed against the surface of the contact rail (5) with a certain force; the runn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com