Method for assembling and disassembling stacking base

A method for disassembly and assembly of stacking seats, which is applied in the field of disassembly and assembly of stacking seats, to achieve the effects of convenient installation and disassembly, improved space utilization, and improved universal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

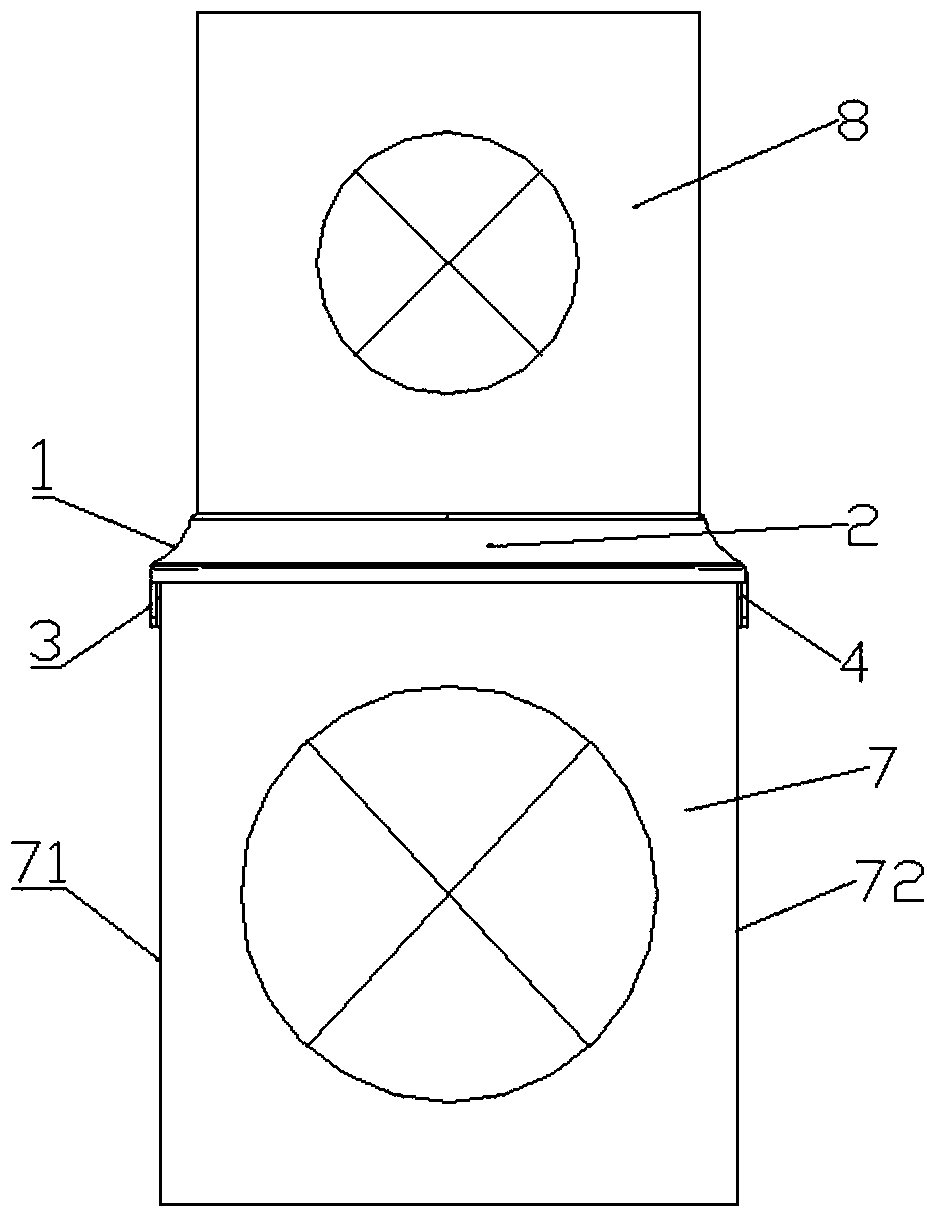

[0059] as attached Figure 1-2 As shown, a stacking seat, the stacking seat 1 is arranged between the lower machine 7 and the upper machine 8, the stacking seat 1 is clamped on the lower machine 7, and the stacking seat 1 includes a receiving seat 2, a fixed splint 3, and a movable splint 4. The receiving seat 2 cooperates with the top panel of the lower machine 7 and the bottom panel of the upper machine 8 respectively, the fixed splint 3 is fixedly connected with the receiving seat 2, and the fixed splint 3 cooperates with the first side panel 71 of the lower machine 7 , the movable splint 4 is detachably connected with the receiving seat 2, and the movable splint 4 cooperates with the second side panel 72 of the lower machine 7.

[0060] Wherein, the lower machine 7 and the upper machine 8 can be any one of conventional washing machines or clothes dryers, at least including the top panel, bottom panel, front panel, rear panel and two side panels common in the prior art, Ho...

Embodiment 2

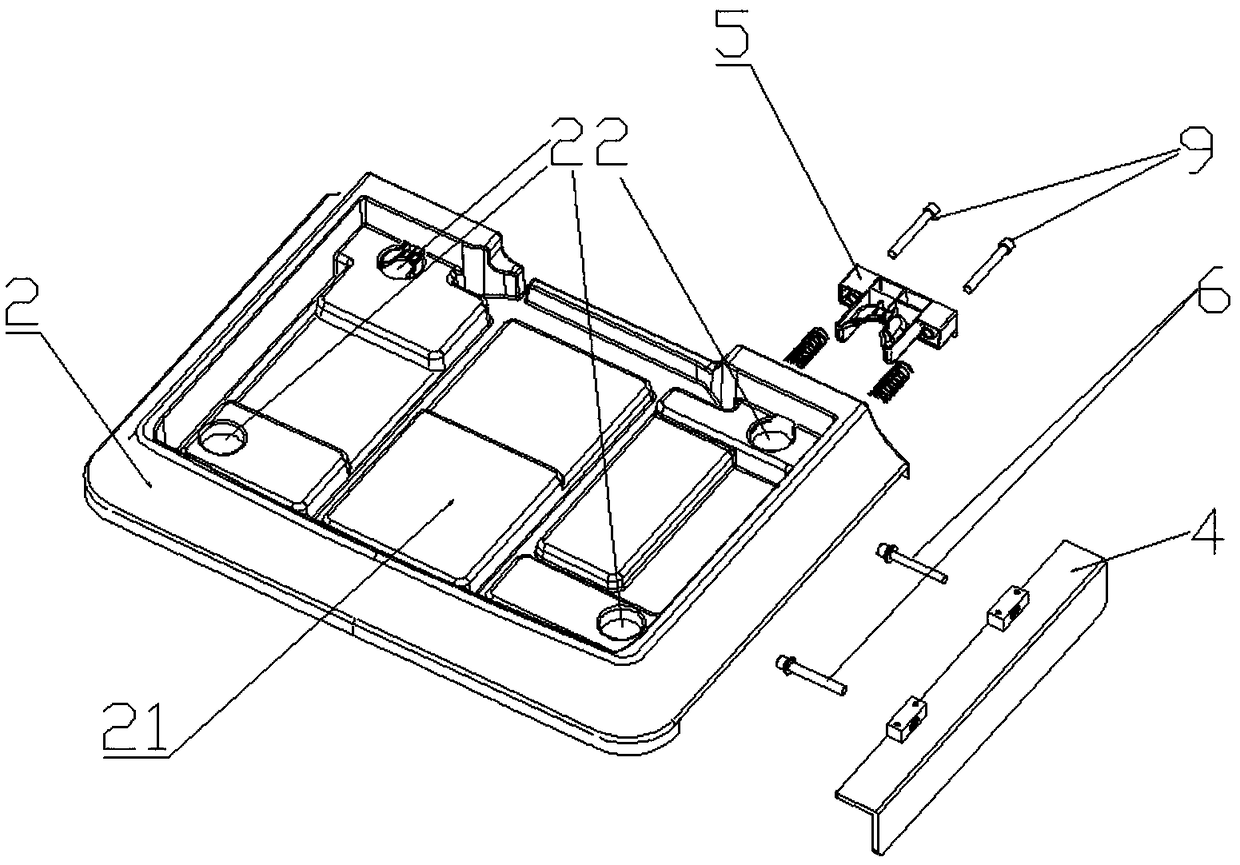

[0066] In order to further illustrate the detachable structure between the receiving seat 2 and the movable splint 4, as attached Figure 3-6 As shown, the receiving seat 2 is provided with a first locking hole 23 on the side connected to the movable splint 4;

[0067] Movable splint 4 comprises side plate 41, assembly plate 42;

[0068] The side plate 41 is connected with the assembly plate 42, and the side plate 41 cooperates with the second side plate 72 of the lower machine 7;

[0069] The assembly plate 42 is provided with an assembly reinforcement part 43, and the assembly reinforcement part 43 is provided with a second locking hole 44;

[0070] The first locking hole 23 cooperates with the second locking hole 44 , and the receiving seat 2 is connected with the movable splint 4 through the locking bolt 6 .

[0071] Preferably, the side plate 41 is matched with the second side plate 72, and the mating surface of the side plate 41 is completely attached to the mating sur...

Embodiment 3

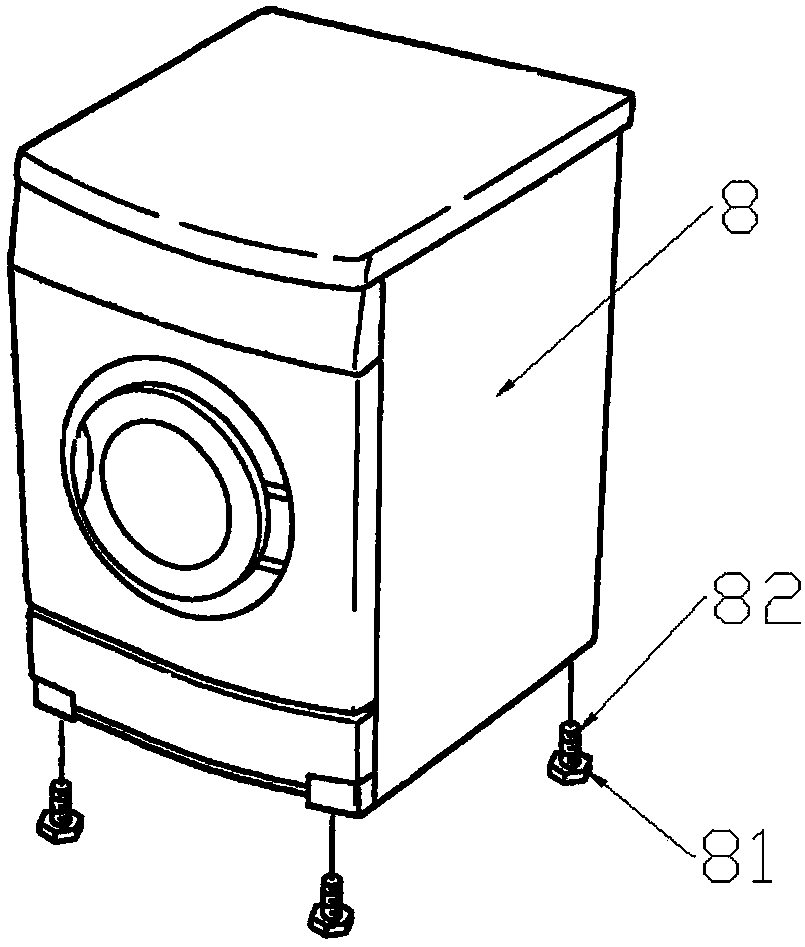

[0079] In order to ensure that the stacking base 1 can be easily and firmly fixed to the upper machine 8, as shown in the attached Figure 2-9 As shown, this embodiment further describes the connection structure between the stacking base 1 and the upper machine 8 .

[0080] In this embodiment, the upper machine 8 is the same as the washing machine / dryer in the prior art, and the bottom panel of the upper machine 8 is provided with a support foot 81, and the support foot 81 is fixedly connected to the bottom panel of the upper machine 8 by a stud 82 superior.

[0081] The receiving seat 2 is provided with a housing part 21 on the side facing the upper machine 8, and the housing part 21 is matched with the bottom panel of the upper machine 8, and a supporting foot receiving groove 22 is provided in the housing part 21 for accommodating the upper machine. 8 supporting feet 81.

[0082] By placing the upper machine 8 on the receiving seat 2, the supporting feet 81 of the upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com