Shunt ring design method

A design method and shunt ring technology, which are applied in mechanical equipment, jet propulsion devices, gas turbine devices, etc., can solve the problems of reducing the ability and scope of stable operation, deterioration of the working state of the fan booster stage, and airflow impact, so as to shorten the calculation time. time, improve the air flow, and ensure the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

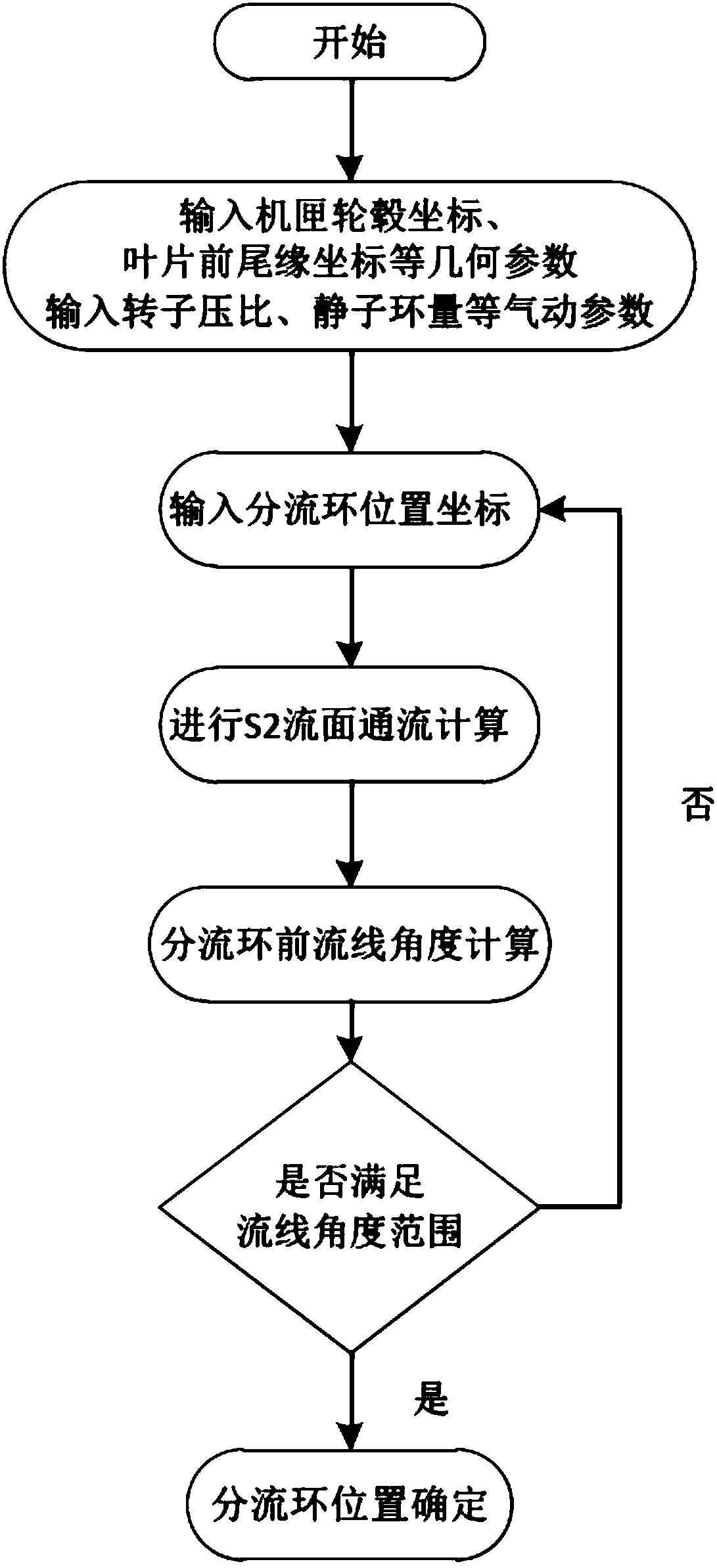

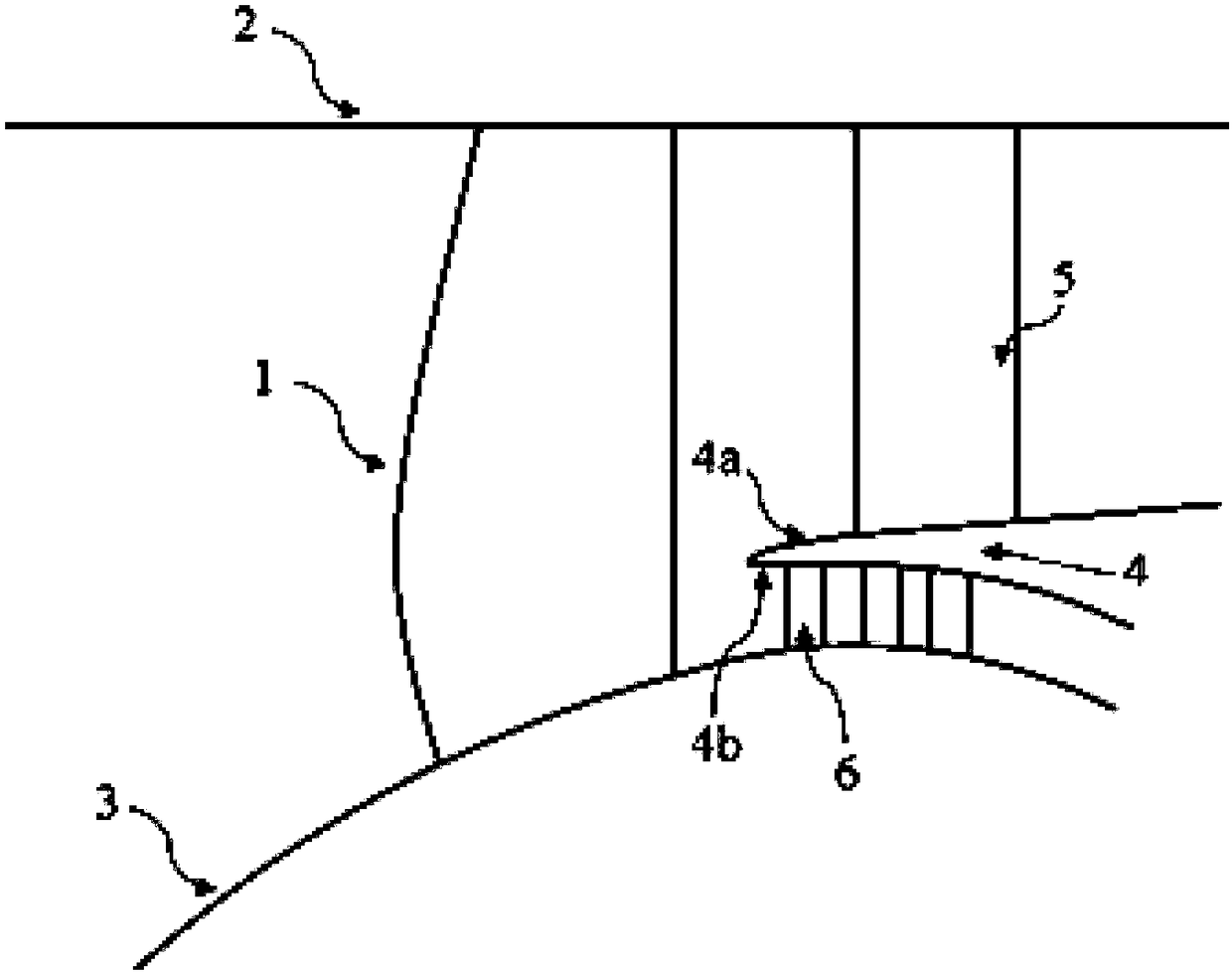

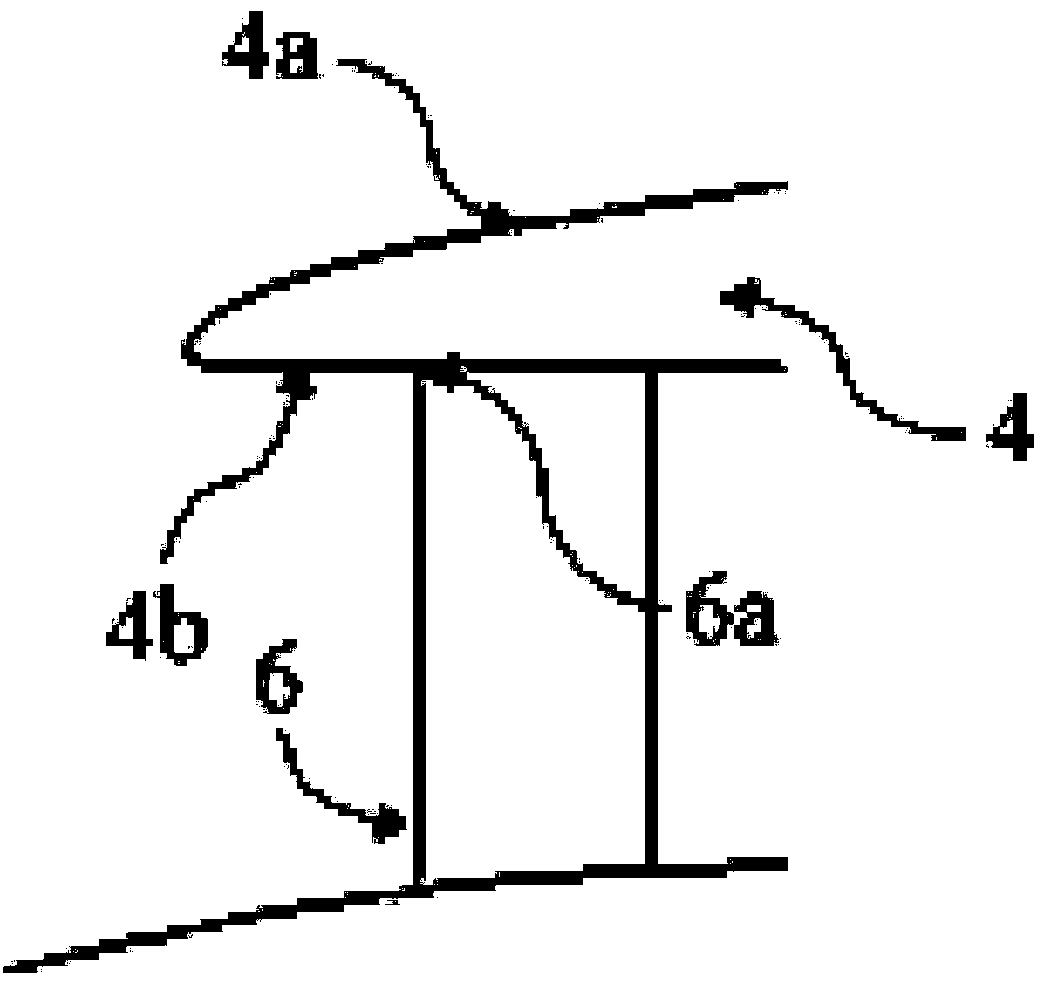

[0032] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0033] The specific embodiments of the present invention are for the convenience of further description of the concept of the present invention, the technical problems to be solved, the technical features constituting the technical solution and the technical effects brought about. It should be noted that the description of these embodiments does not constitute a limitation of the present invention. In addition, the technical features involved in the embodiments of the present invention described below may be combined with each other as long as they do not conflict with each other.

[0034] In order to simplify and solve the complex three-dimensional flow inside the turbomachinery, Mr. Wu Zhonghua proposed the quasi-three-dimensional idea of the S1 and S2 flow surface iteration theory in 1952. Among them, the flow su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com