Online full-automatic wall thickness measurement device for nodular cast iron pipe

A nodular cast iron pipe, fully automatic technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of inability to meet the quality monitoring requirements of large-scale production lines, low detection efficiency, and limited detection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0032] In the present invention, unless otherwise specified, the orientation words included in the term such as "up, down, left, right, front, back, inside and outside" only represent the orientation of the term in the normal use state, or the common name understood by those skilled in the art. , and should not be construed as a limitation of this term.

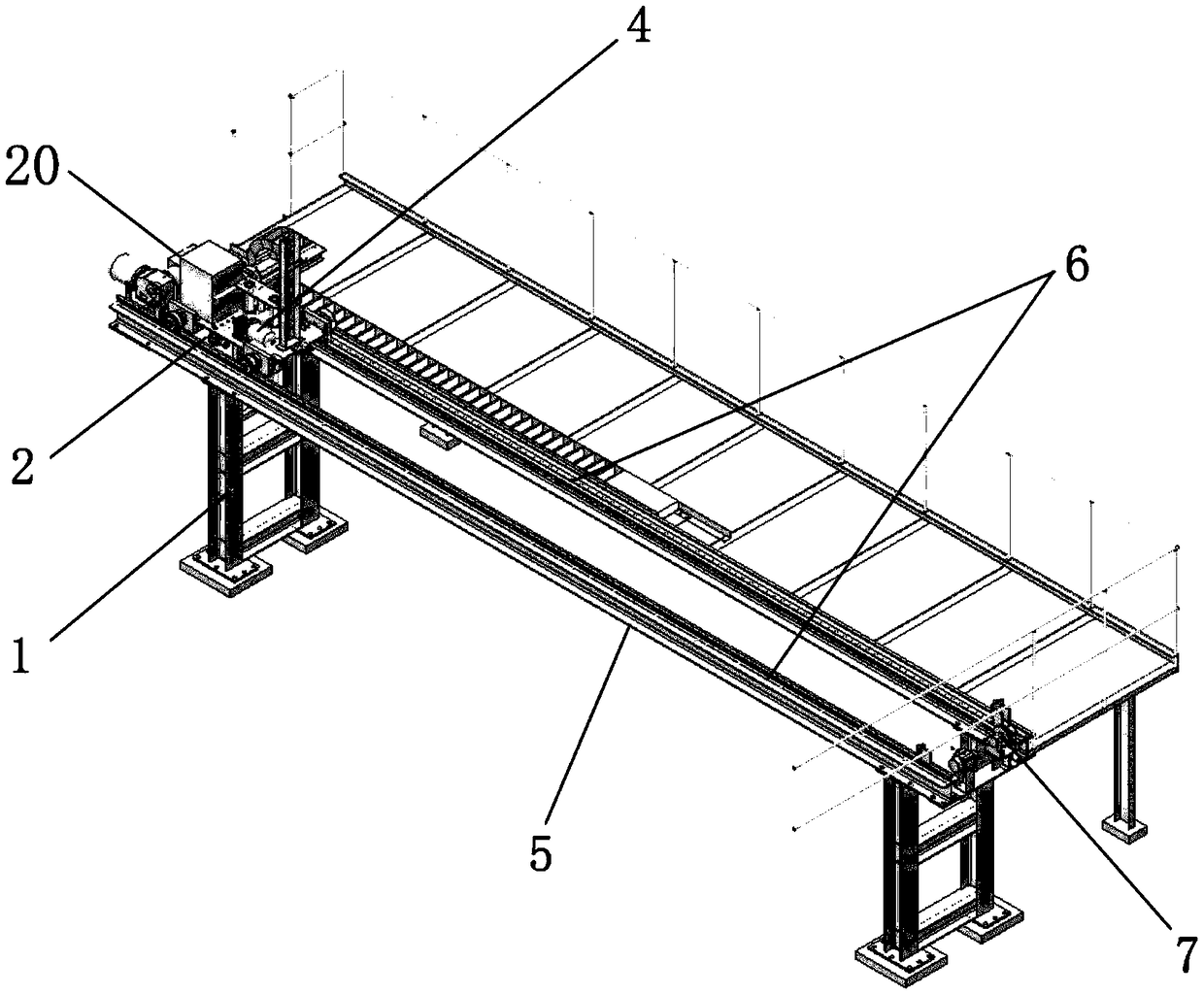

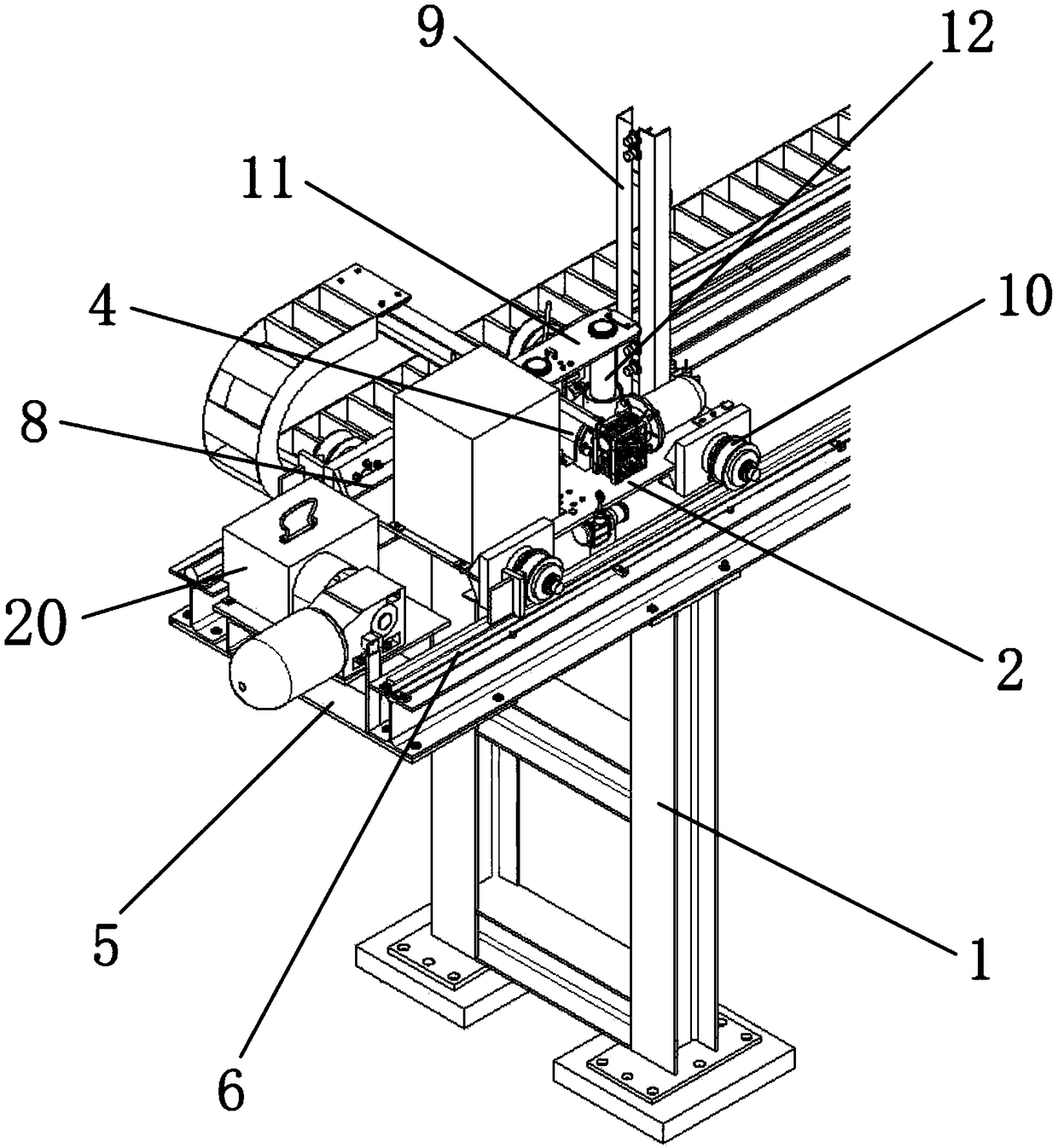

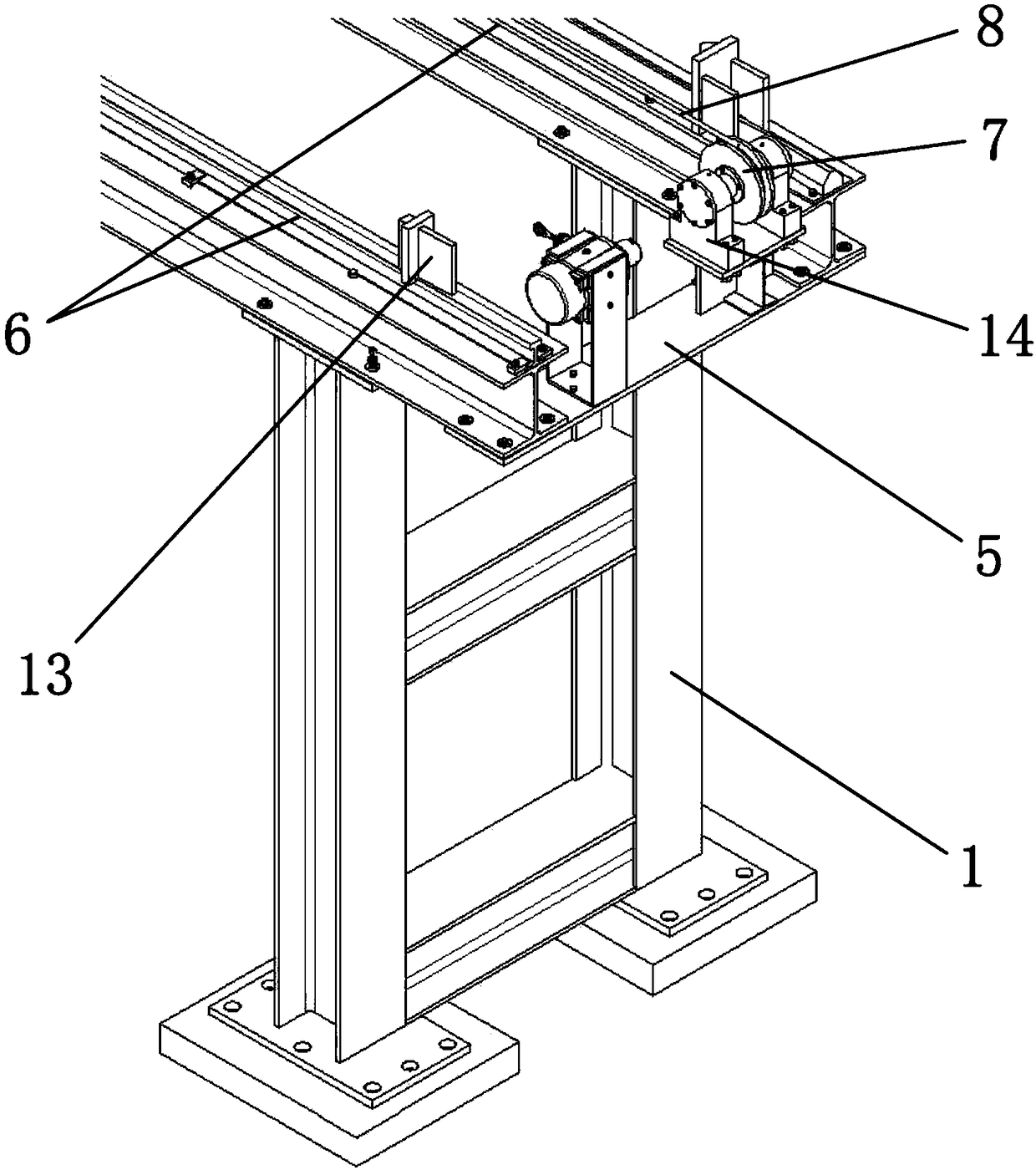

[0033] See attached Figure 1-5 The online automatic wall thickness detection equipment for ductile iron pipes shown in the figure, the online automatic wall thickness detection equipment for ductile iron pipes includes a steel frame body 1 and a car body 2, the top of the steel frame body 1 is provided with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap