Setting method of equipment management KPI system in refining and petrochemical enterprises

A device management, enterprise technology, applied in data processing applications, instruments, resources, etc., can solve problems such as low management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

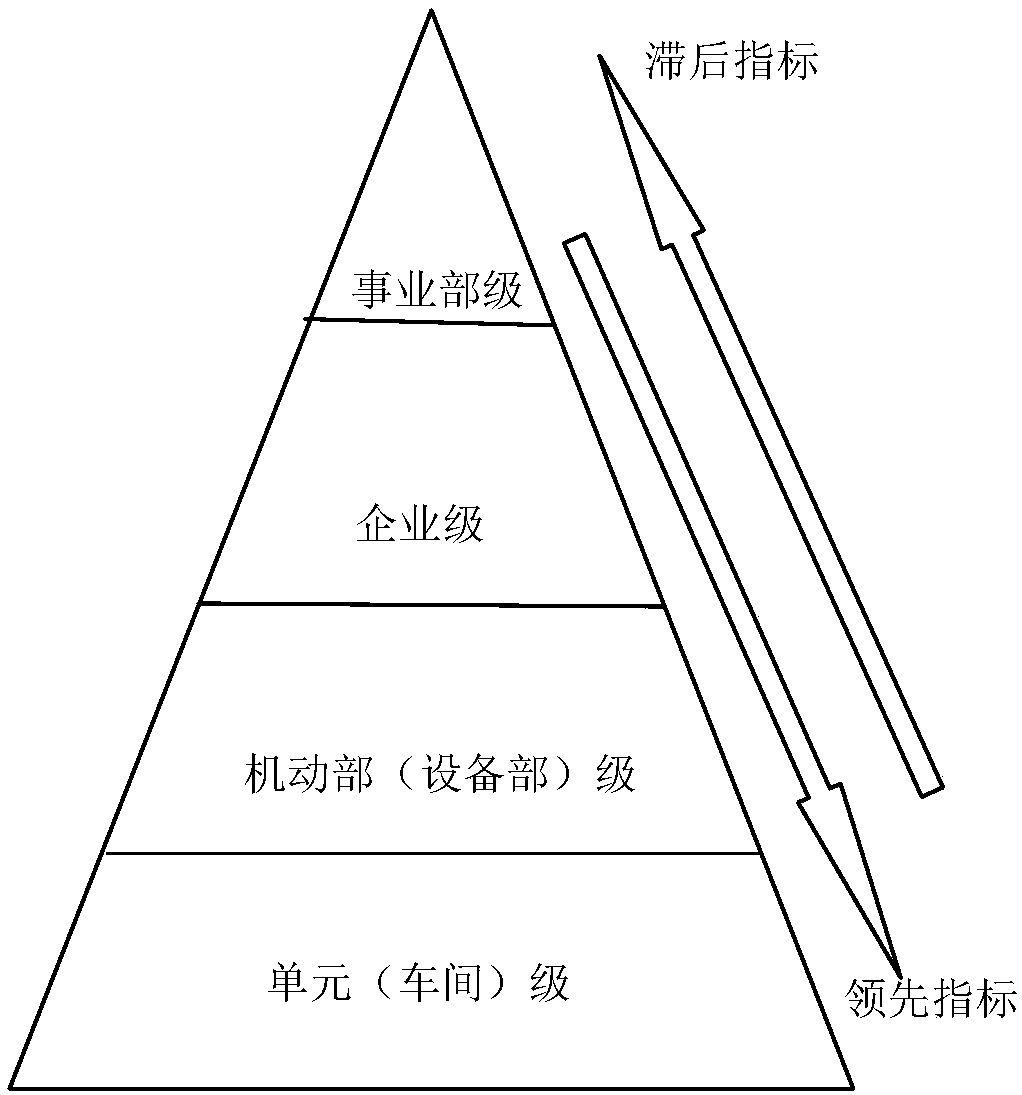

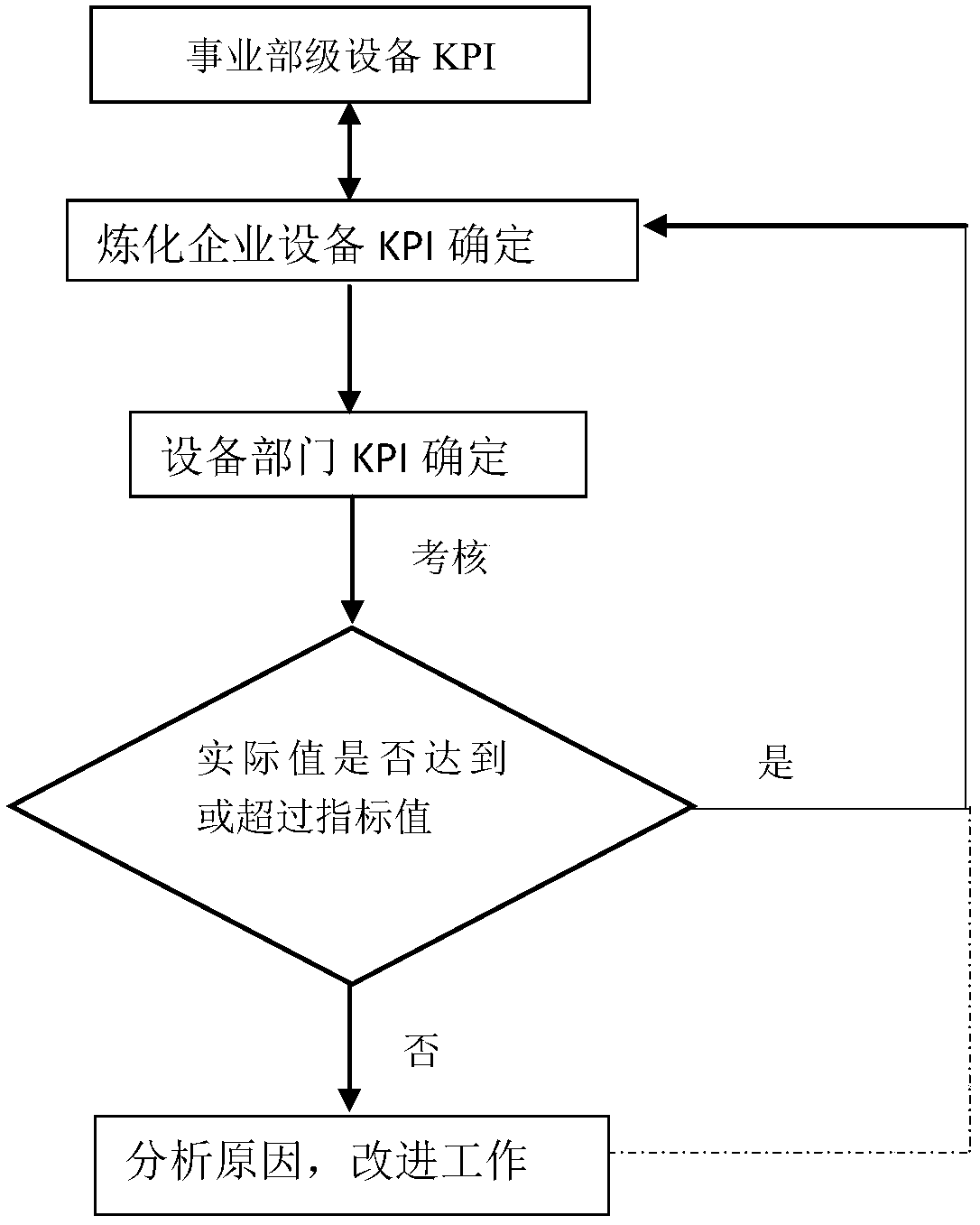

[0016] Such as figure 1 As shown, the setting of the equipment management KPI system of refining and chemical enterprises first considers the hierarchical setting, which is divided into four levels: refining business department, refining and chemical enterprise, mobile department (equipment department), and unit / workshop, which is compatible with the current management organization setting . In terms of content setting, considering the characteristics of modern management, specific index content and calculation methods are proposed from the aspects of economy, technology, reliability, safety, and integrity, and relevant indicators are set. Form the equipment management KPI system of refining and chemical enterprises from the two dimensions of level and content, and then guide the refining and chemical enterprises to set equipment management KPI indicators. The department-level indicators of the refining business can be compared with international companies and can be compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com