Guiding installing structure for vending machine tray

A technology of vending machine and installation structure, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. Realize the effect of simple assembly structure of guide rail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

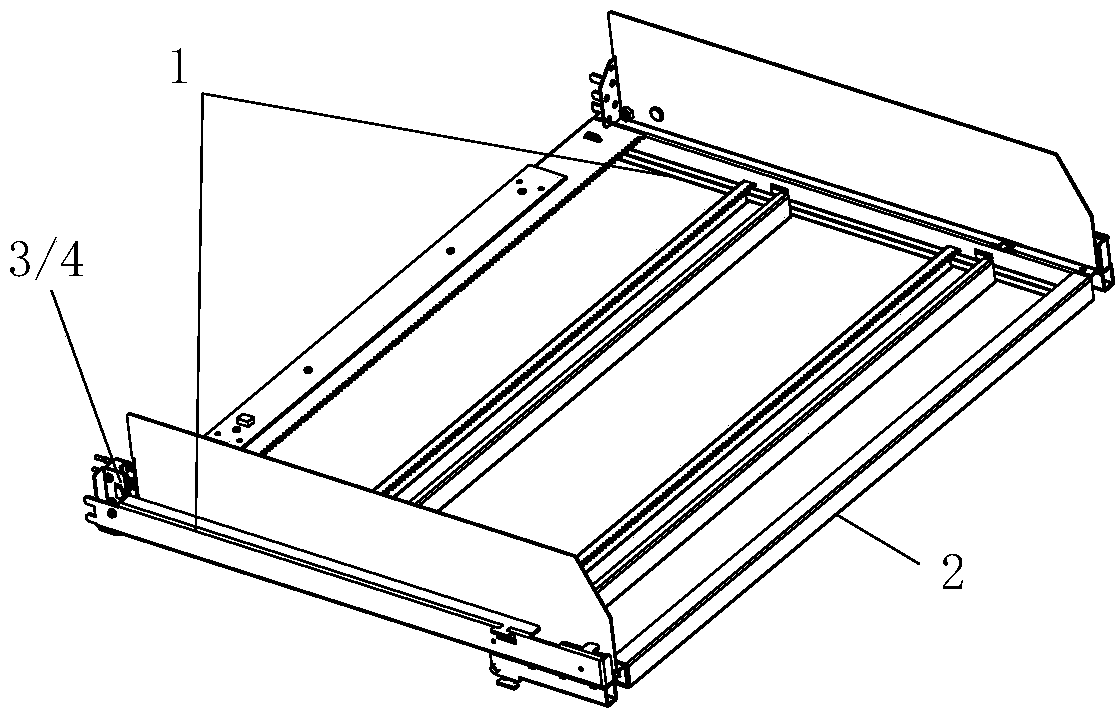

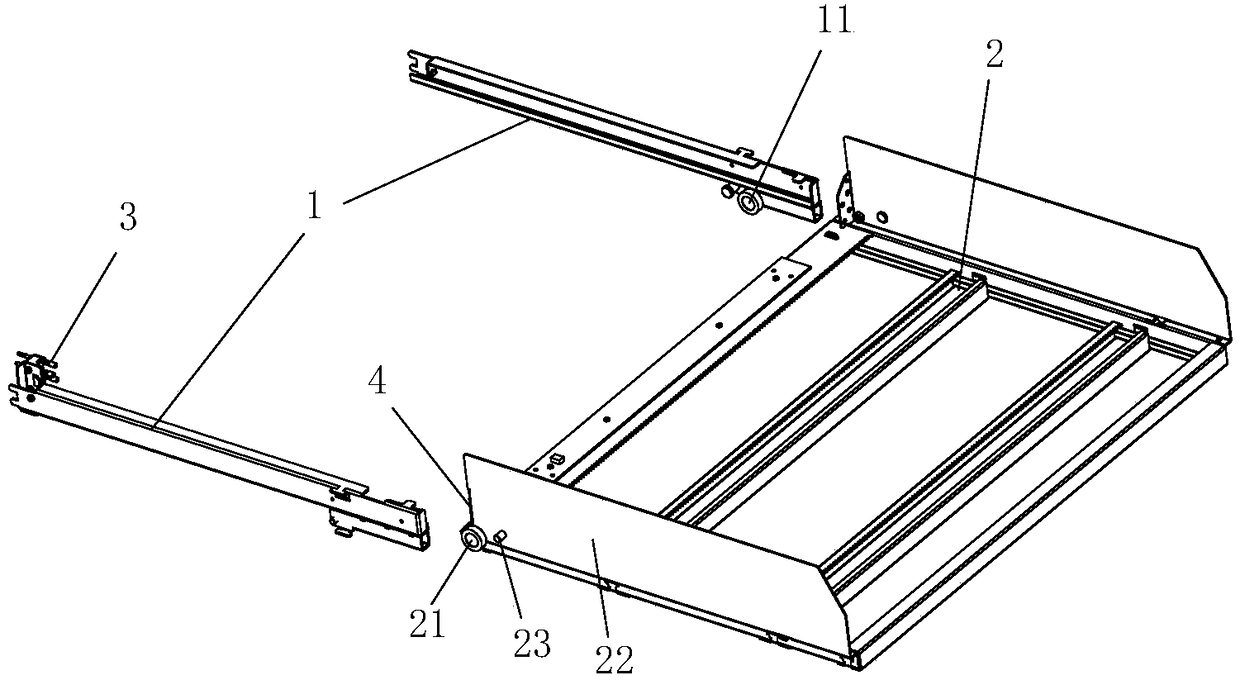

[0036] see figure 1 and figure 2 , a pallet structure for automatic vending machines in the illustration is a preferred solution for applying the present invention, the pallet 2 is assembled between two sets of parallel guide rails 1 through roller guides, and the guide rails 1 are fixed on the body of the automatic vending machine Inside, realize the installation of the tray inside the vending machine.

[0037] It should be noted that the front and rear directions referred to in this embodiment are defined relative to the installation and removal positions of the tray. For example, if the tray is loaded from the front end of the guide rail, pushed into the rear end of the guide rail and installed in place, it is not necessarily the same as There is a one-to-one correspondence between the front and back positions of the vending machine.

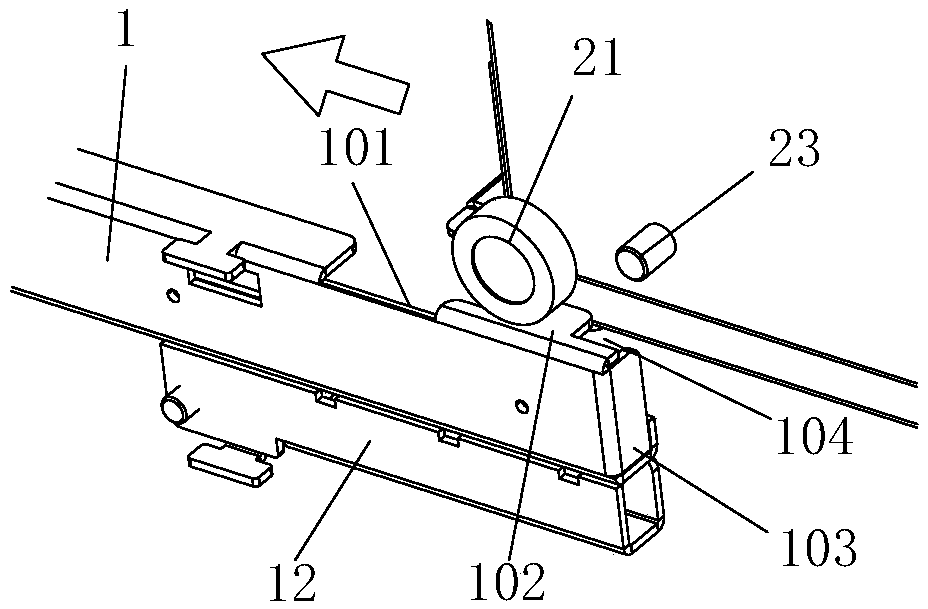

[0038] See respectively figure 1 , figure 2 , Figure 6 as well as Figure 8 , the pallet adopting the installation structure of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com