Sealing structure between batteries with multiple cells and forming method of the sealing structure

A single-cell battery and sealing structure technology, which is applied in the direction of sealing materials, structural parts, battery boxes/coatings, etc., can solve the problems of battery performance and quality that cannot be guaranteed, and achieve the effect of simple structure, high bonding strength and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

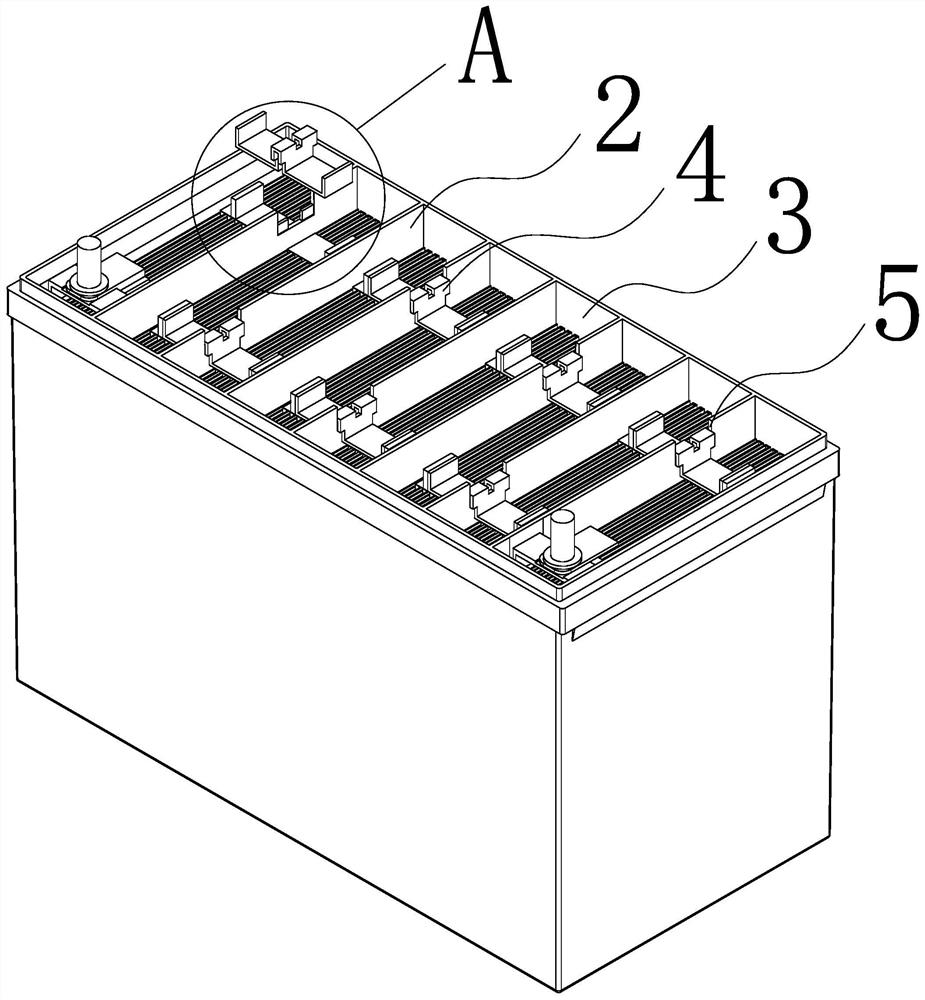

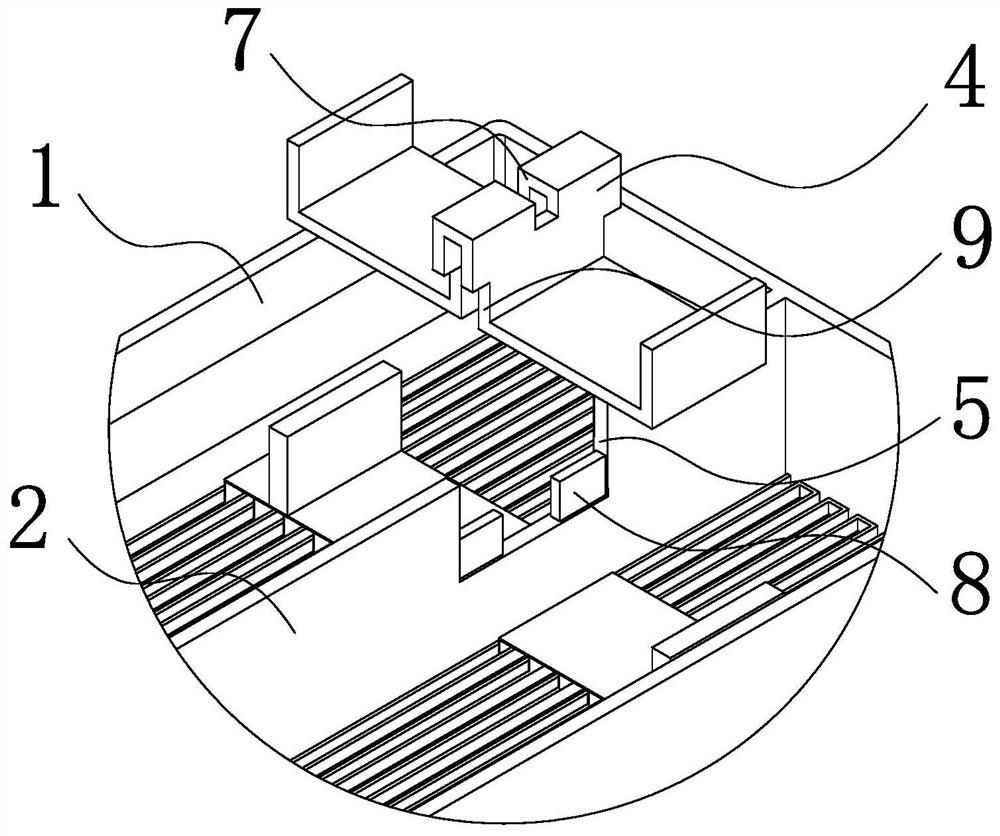

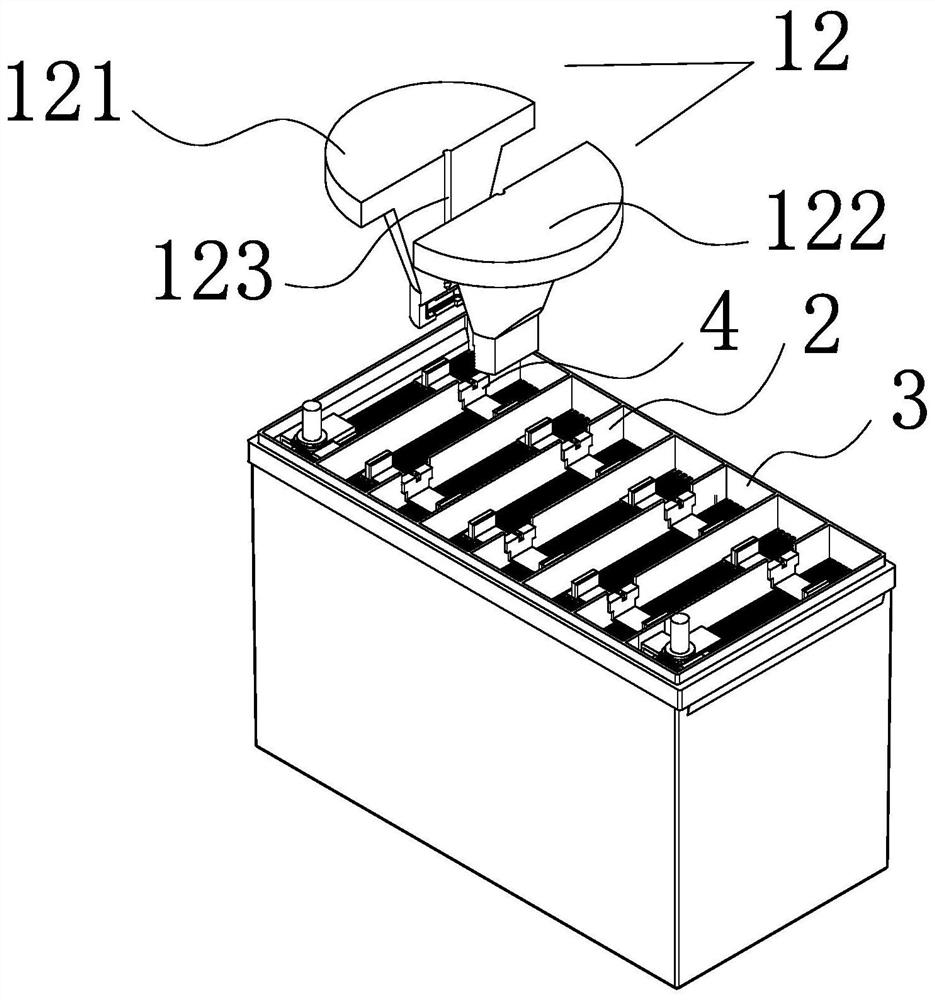

[0025] like figure 1 As shown, a sealing structure between batteries with multiple cells of the present invention includes a battery case 1 in the shape of a cuboid. In the cavity of the battery case 1, several longitudinal separators 2 are arranged equidistantly along the length direction. The battery case 1 The cavity is divided by the medial partition 2 to form several battery slots 3, and the two ends above the medial partition 2 are provided with square bridge gaps 5 that can accommodate the passage of the bridge connector 4, such as figure 2 and Figure 4 As shown, the bridge connector 4 is a U-shaped structure with the opening facing downwards. The U-shaped bridge connector 4 is clamped on both sides of the bottom of the bridge gap 5, and its open ends are respectively along the battery slot 3 on the corresponding side. The water on the top surface of the battery sheet extends outwards, and the bridge connector 4 corresponding to the bridge gap 5 is covered with a wra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com