Harvesting table of corn harvesting machine

A corn harvester and harvesting table technology, applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of long time wasted, cumbersome and time-consuming to adjust the ear picking board, so as to reduce crop losses, reduce losses, reduce Loss-avoiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

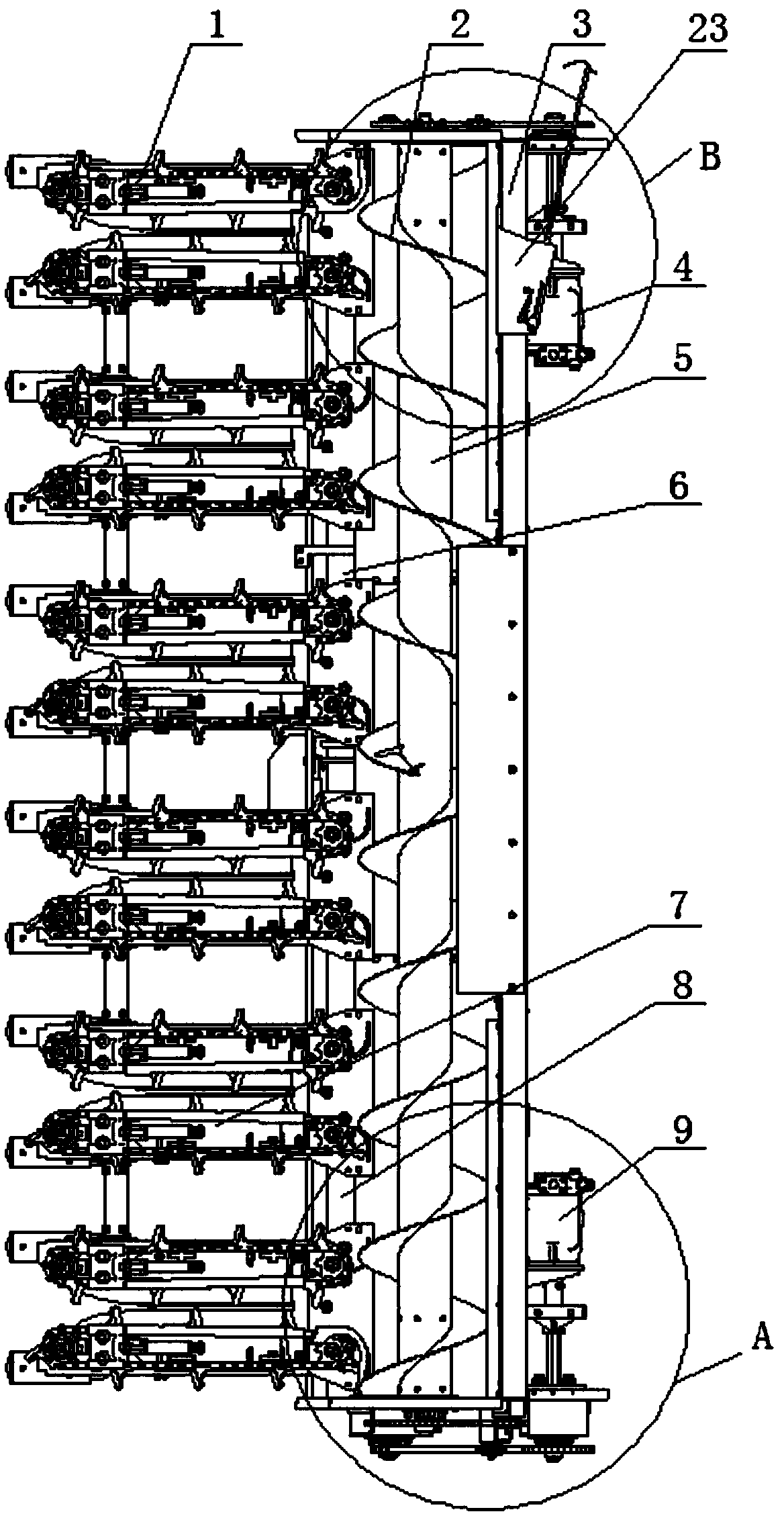

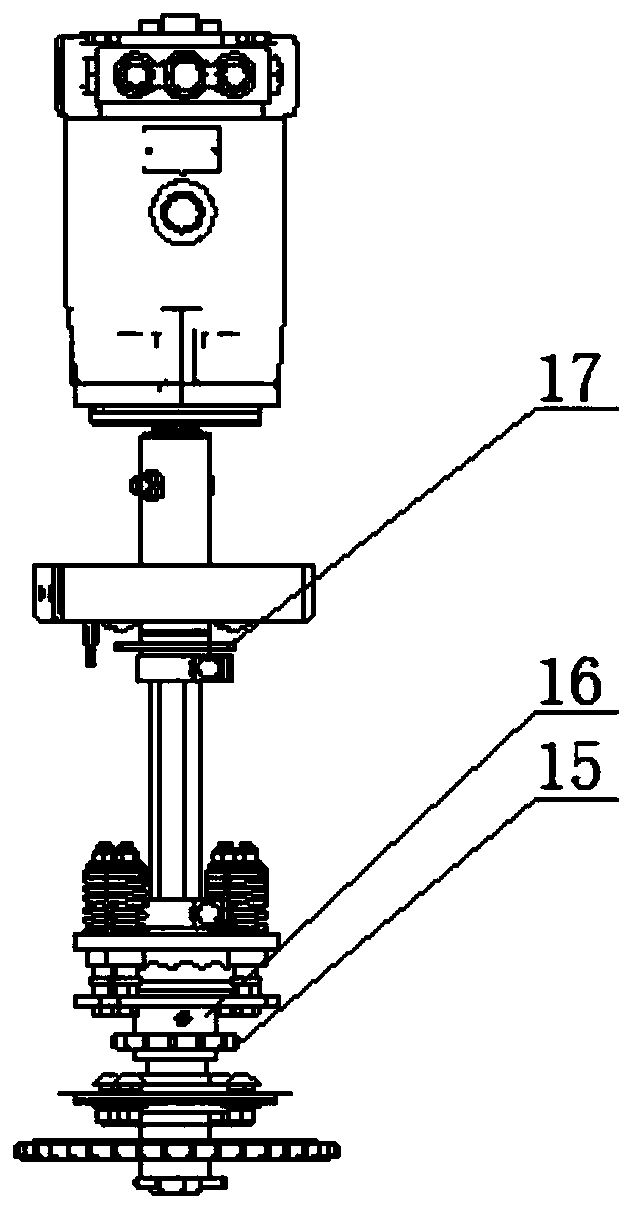

[0038] A corn harvester harvesting platform, such as figure 1 As shown, it includes the header frame body 3, the fringe picking mechanism 1 and the cage stirring mechanism 2, the fringe picking mechanism includes the fringe picking drive shaft and some fringe picking components 7, and the fringe picking mechanism is installed on the header frame body through the fringe picking drive shaft , The cage-stirring mechanism is installed on the header frame body by the cage-stirring drive shaft 5 .

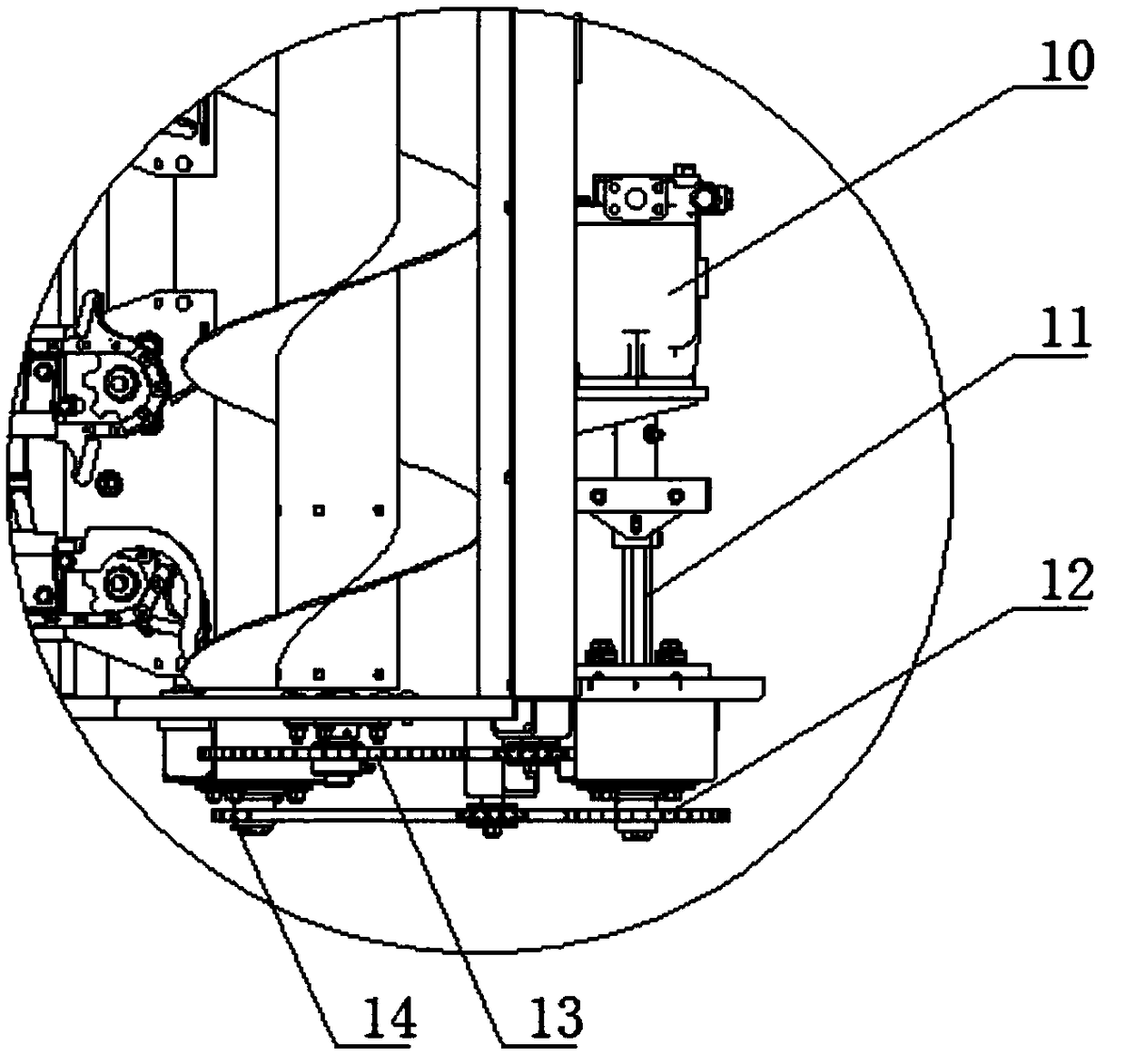

[0039]The innovation of the harvesting platform of the corn harvester is that the left input shaft drive assembly 9 and the right input shaft drive assembly 4 are respectively installed at the two ends of the header frame body. Picking fringe drive sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com