Jaw crusher

A technology for jaw crushers and jaw plates, which is applied in the fields of dust removal, cleaning methods and tools, grain processing, etc., and can solve problems affecting the normal use of jaw crushers, threatening the physical and mental health of workers, and dust accumulation in jaw crushers, etc. problems, to achieve good environmental performance, reduce health damage, and improve the effect of smoke and dust environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

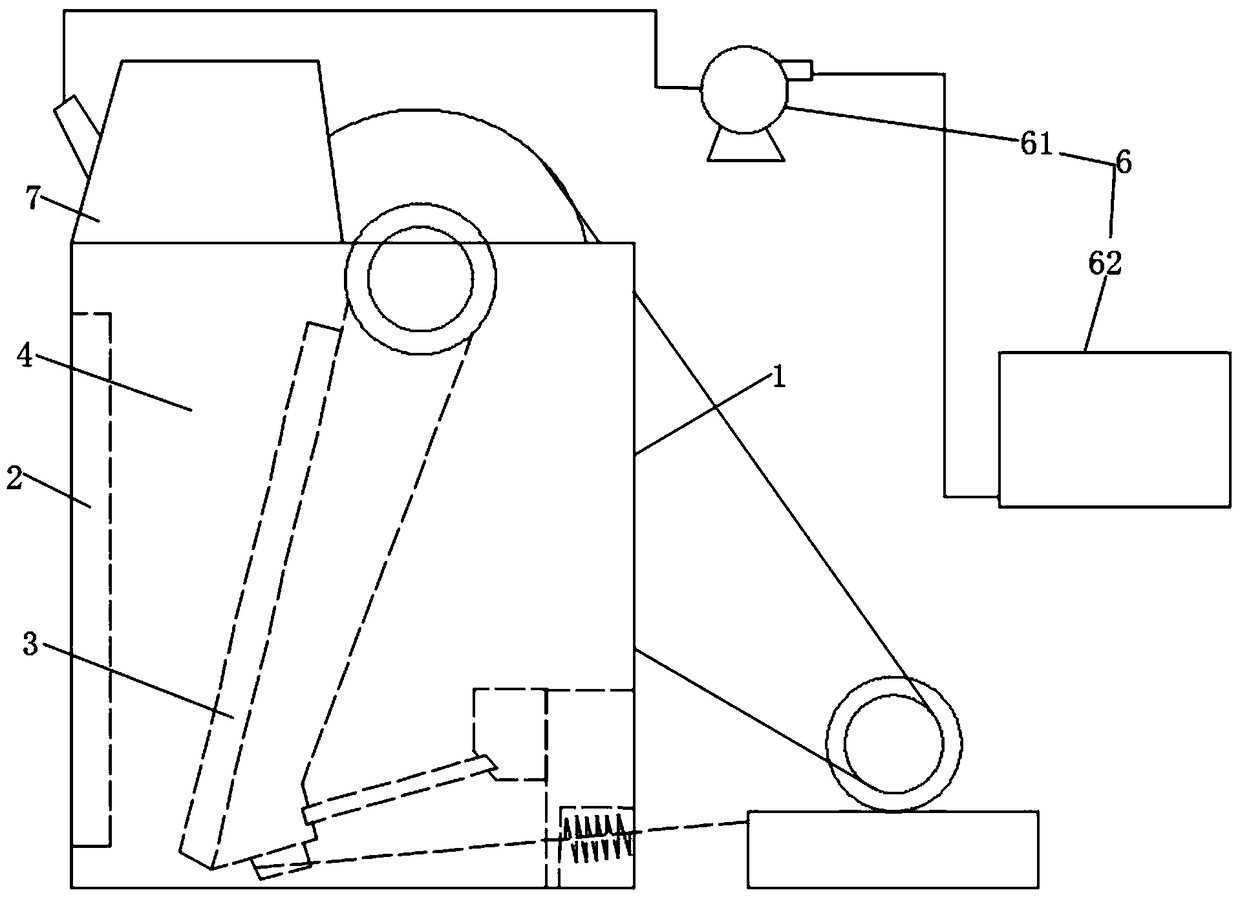

[0018] Example: such as figure 1 As shown, the jaw crusher of this embodiment includes a jaw crusher body and a dust removal device 6;

[0019] A static jaw plate 2 is vertically provided on the inner wall of the chassis 1 side of the jaw crusher body, and a movable jaw plate 3 is arranged inside the chassis 1. The movable jaw plate 3 is obliquely arranged on the side of the static jaw plate 2. The movable jaw plate 3 is connected to the driving device in transmission, and the driving device drives the upper end of the movable jaw plate 3 to swing close to or away from the above-mentioned static jaw plate 2, and a crushing chamber 4 is formed between the above-mentioned static jaw plate 2 and the above-mentioned movable jaw plate 3;

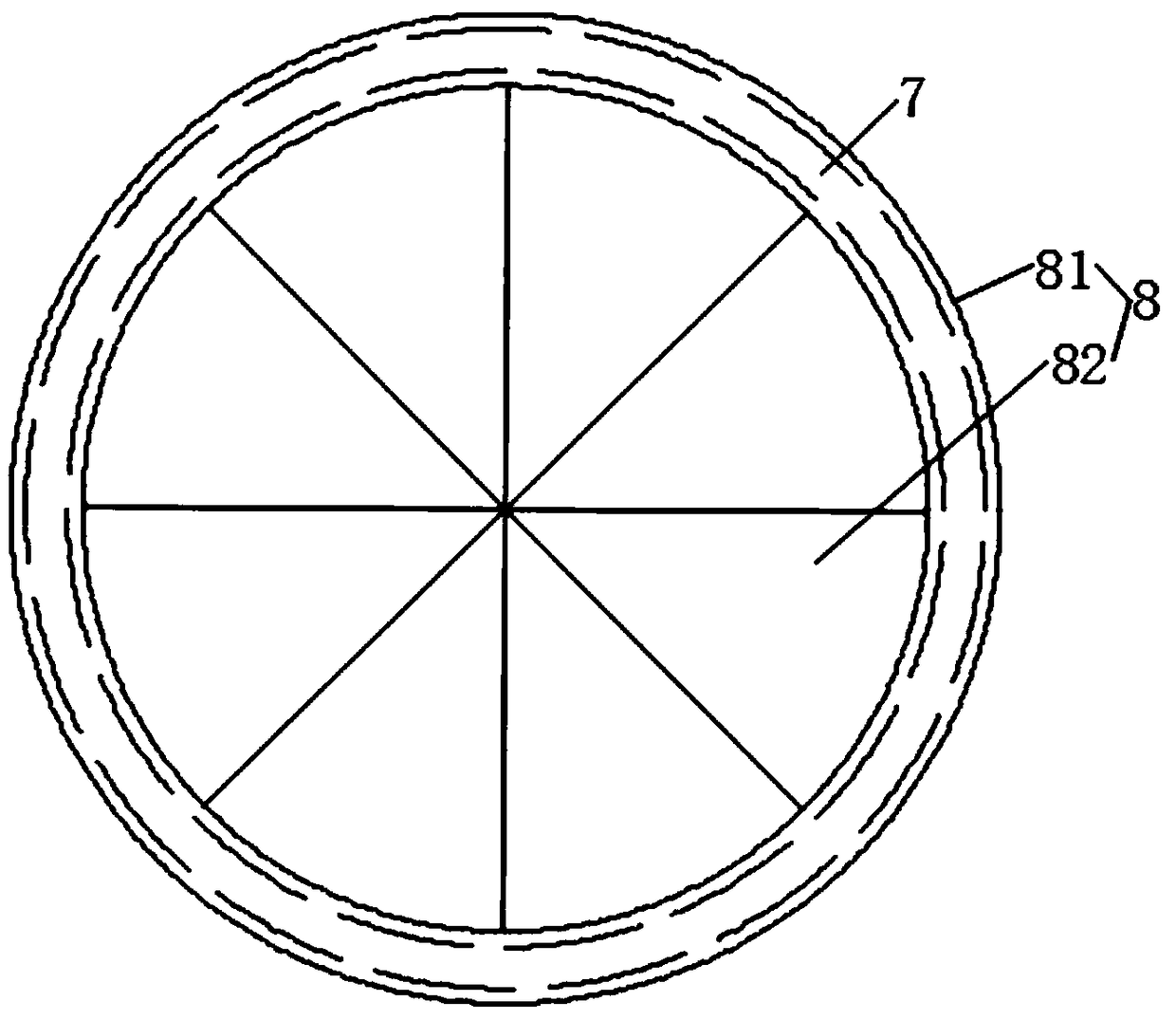

[0020] The upper end of the crushing chamber 4 is sealed and connected with a vertical feed pipe 7, and the upper end of the feed pipe 7 is covered with a flexible dust-shielding member 8, which can be opened or closed under the action of an exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com