Cleaning device for paint bottles of handicrafts

A technology for cleaning devices and handicrafts, applied in the field of handicrafts, can solve the problems of incomplete cleaning and large floor space, and achieve the effect of improving the utilization rate of the room and reducing the floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

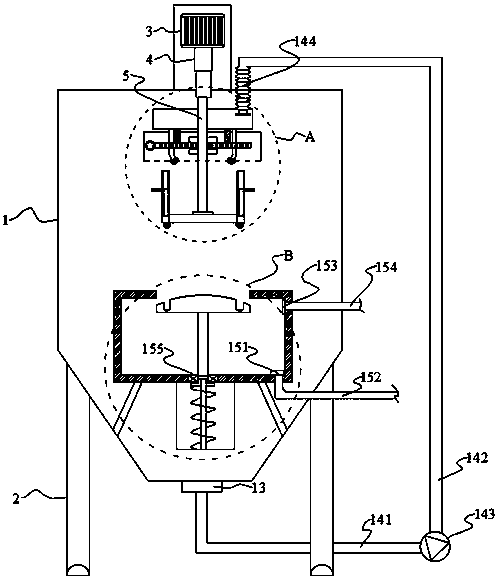

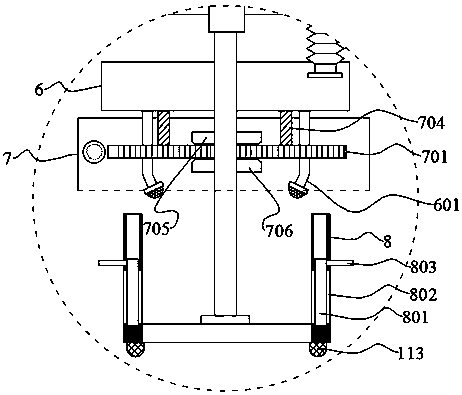

[0031] This embodiment includes a housing 1, the lower end of the housing 1 is provided with a water outlet 13, the lower end of the housing 1 is provided with a leg 2, and the upper end of the housing 1 is provided with a hydraulic cylinder 3, the hydraulic cylinder 3 The telescoping shaft 4 is connected with a connecting rod 5, and the lower end of the connecting rod 5 passes through the inner wall of the housing 1 and is connected with a cleaning box 8. The periphery of the connecting rod 5 is also provided with a water storage tank 6, and the water storage tank The lower end of 6 is connected with a plurality of nozzles 601; the bottom of the cleaning box 8 is also provided with a soaking box 9, and a support 10 is connected between the soaking box 9 and the housing 1, and the upper end of the soaking box 9 is provided with a cleaning box of the same size. 8 openings that match each other, the soaking box 9 is provided with a water baffle 11 that matches the size of the ope...

Embodiment 2

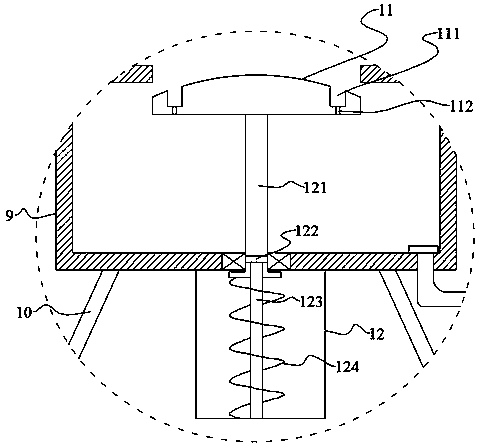

[0034]This embodiment is further optimized on the basis of Embodiment 1 as follows: the lifting device includes a hollow sleeve 121, a guide rod 123, a return spring 124, a limit block 122 and a storage box 12, and the hollow sleeve 121 The upper end is connected to the lower end of the water retaining plate 11. The lower end of the hollow sleeve 121 penetrates the outer wall of the soaking barrel and extends into the storage box 12. The storage box 12 is located at the lower end of the soaking box 9. The storage box 12 is provided with Guide rod 123, the lower end of the guide rod 123 is connected to the lower end inner wall of the storage box 12, the upper end of the guide rod 123 is inserted into the hollow sleeve 121 and connected to the stop block 122, and the return spring 124 sets Located outside the guide rod 123 , the return spring 124 is located between the hollow sleeve 121 and the inner wall of the lower end of the storage box 12 .

[0035] After adopting this tech...

Embodiment 3

[0037] This embodiment is further optimized on the basis of embodiment 2 as follows: a sealing ring 155 is arranged between the hollow sleeve 121 and the soaking tank 9 .

[0038] After adopting the outlined scheme, a sealing ring 155 is arranged between the hollow sleeve 121 and the outer wall of the soaking box 9, which effectively prevents the soaking liquid in the soaking box 9 from entering the storage box 12 when the hollow sleeve 121 moves up and down. Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com