A Control Method for Eliminating Node Errors in Logistics System

A technology of a logistics system and control method, which is applied to conveyor control devices, conveyor objects, mechanical conveyors, etc., can solve the problems of accumulating errors affecting the normal operation of the system, frequent manual intervention in operation, etc., so as to improve operation efficiency and ensure normal operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

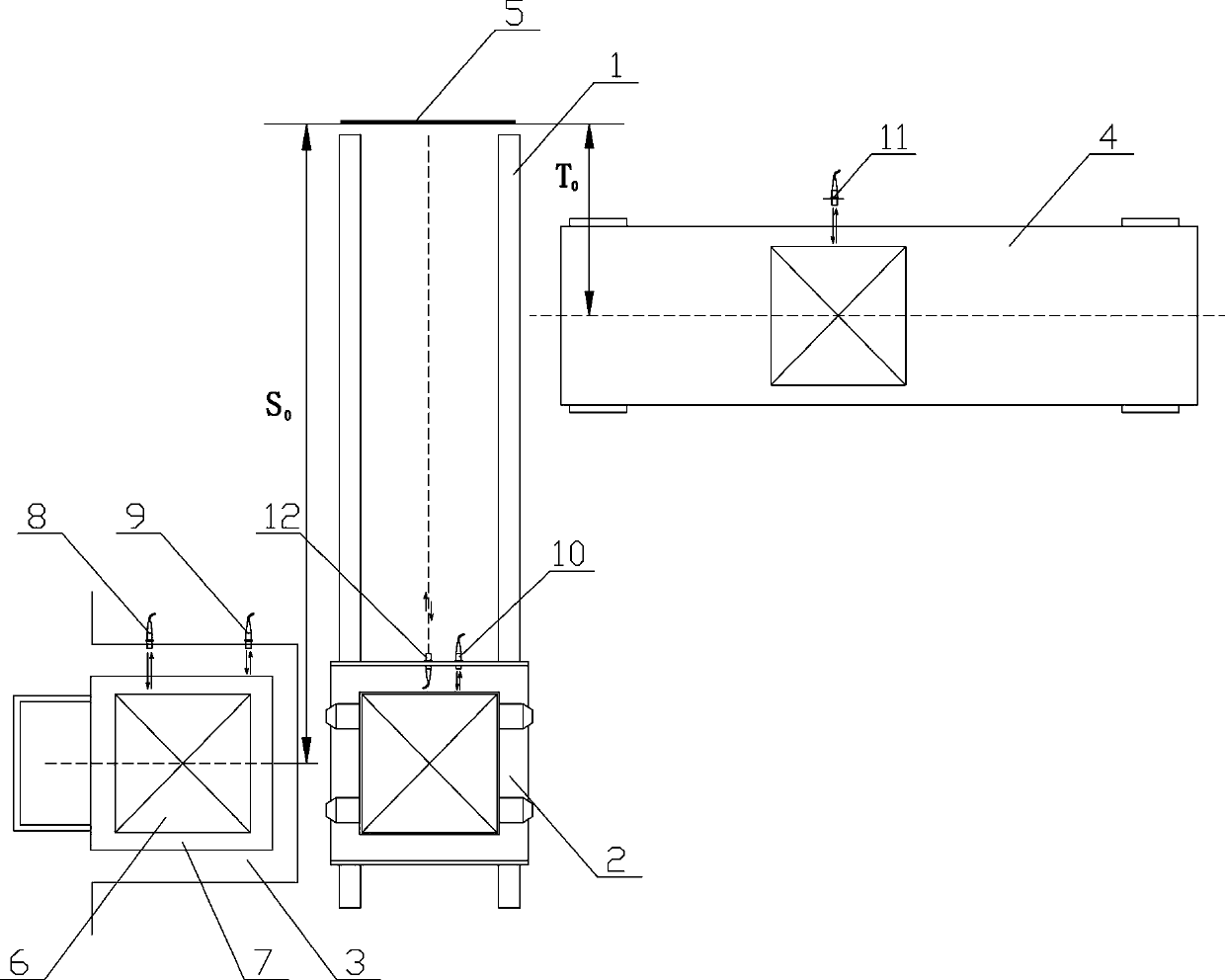

[0021] see figure 1 , a control method for eliminating node errors in a logistics system, the logistics system includes a shuttle track 1, a shuttle 2, and cargo spaces 3 and conveyor lines 4 arranged on both sides of the shuttle track 1, wherein the conveyor line 4 adopts Belt conveyor; a laser reflector 5 is installed on the right end of the shuttle track 1, and a carrier 7 for carrying goods 6 is parked on the cargo space 3, wherein the carrier 7 is a trolley; the right side of the cargo space 3 is installed There are photoelectric detection switch A8 and photoelectric detection switch B9, the photoelectric detection switch A8 and photoelectric detection switch B9 are respectively used to detect the placement position of the cargo and the carrier on the cargo space; the photoelectric detection switch C10 is installed on the right side of the shuttle car 2 , the photoelectric detection switch C10 is used to detect the placement position of the goods 6 on the shuttle car 2; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com