Steel corbel pre-embedded structure and construction method thereof

A technology of steel corbels and corbels, which is applied in the construction of buildings, railways without foundation support structures, highways, and municipal fields. It can solve the problems of difficult dismantling of formwork, inability to reuse, waste of resources, etc., to speed up the dismantling time and simplify the dismantling of formwork Convenience, waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

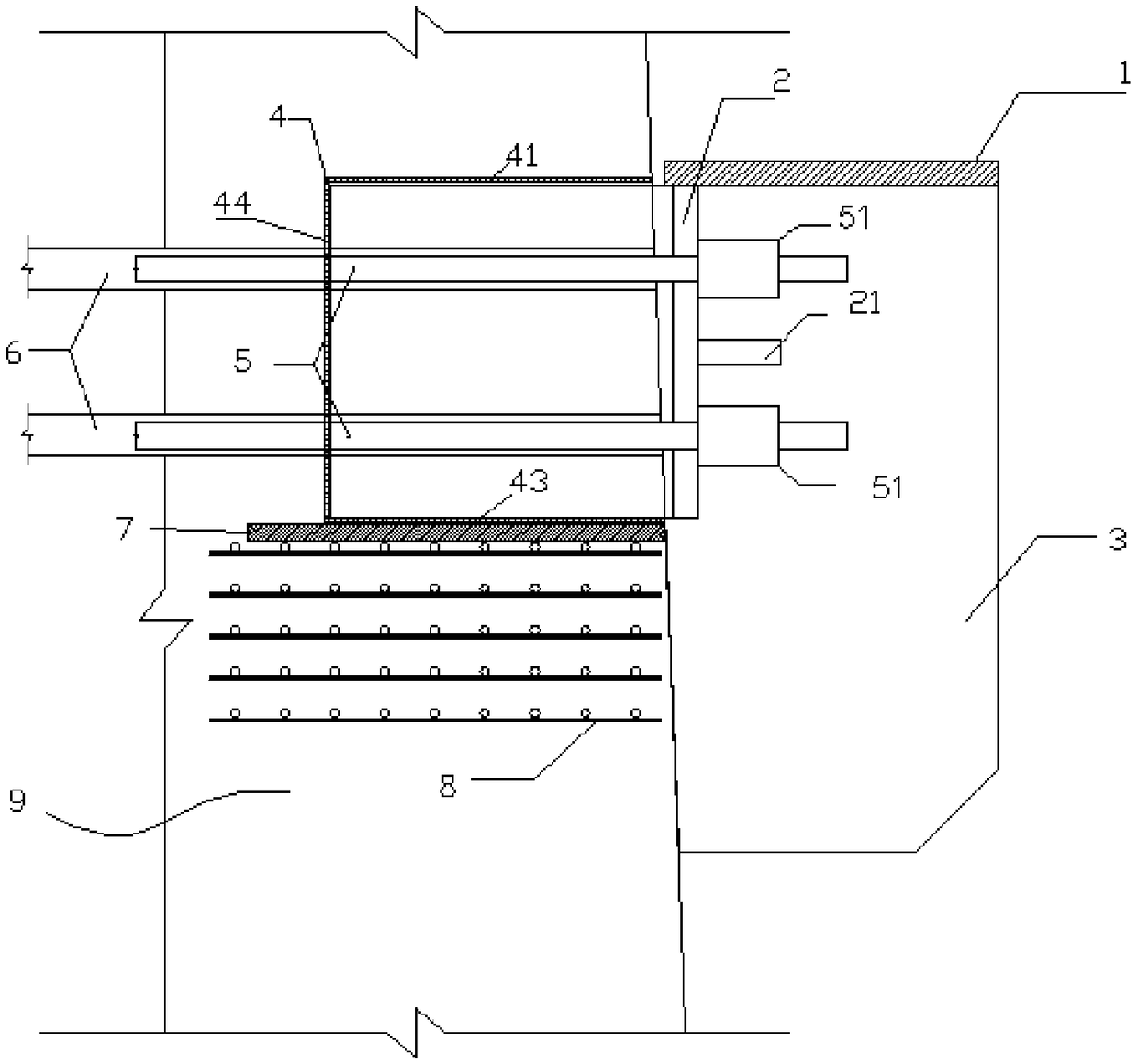

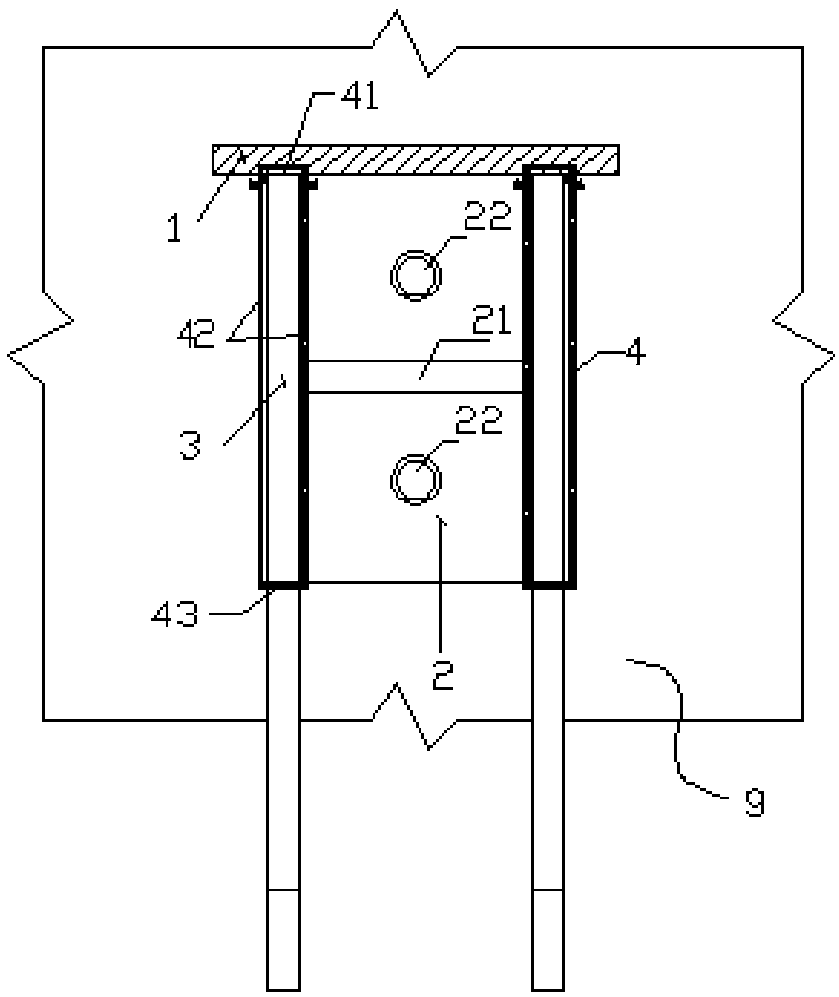

[0026] Embodiment 1: as attached Figure 1~2 As shown, a steel corbel pre-embedded structure, which includes a concrete column 9, a corbel horizontal steel plate 1, a corbel transverse connecting steel plate 2 and a corbel vertical steel plate 3, and the corbel vertical steel plates 3 are two symmetrically arranged Inverted L-shaped plate-shaped structure, the vertical corbel horizontally connected steel plate 2 is welded between the middle part of the corbel vertical steel plate 3, and one end of the corbel vertical steel plate 3 extends into the concrete column 9, and the corbel vertical The other end of the steel plate 3 is located on the side of the concrete column 9, the horizontal steel plate 1 of the corbel is welded and connected to the outer top of the vertical steel plate 3 of the corbel, and the embedded steel pipe 6 is arranged in the concrete column 9, and there is a steel pipe 6 in the embedded steel pipe 6 For the drawn and finished-rolled threaded steel 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com