Integrated device for casing damage well composite repair

A composite material and subsidy technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of high protection and requirements of the pipe body during the expansion process, increasing the difficulty of operation and handling, and inability to pull out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

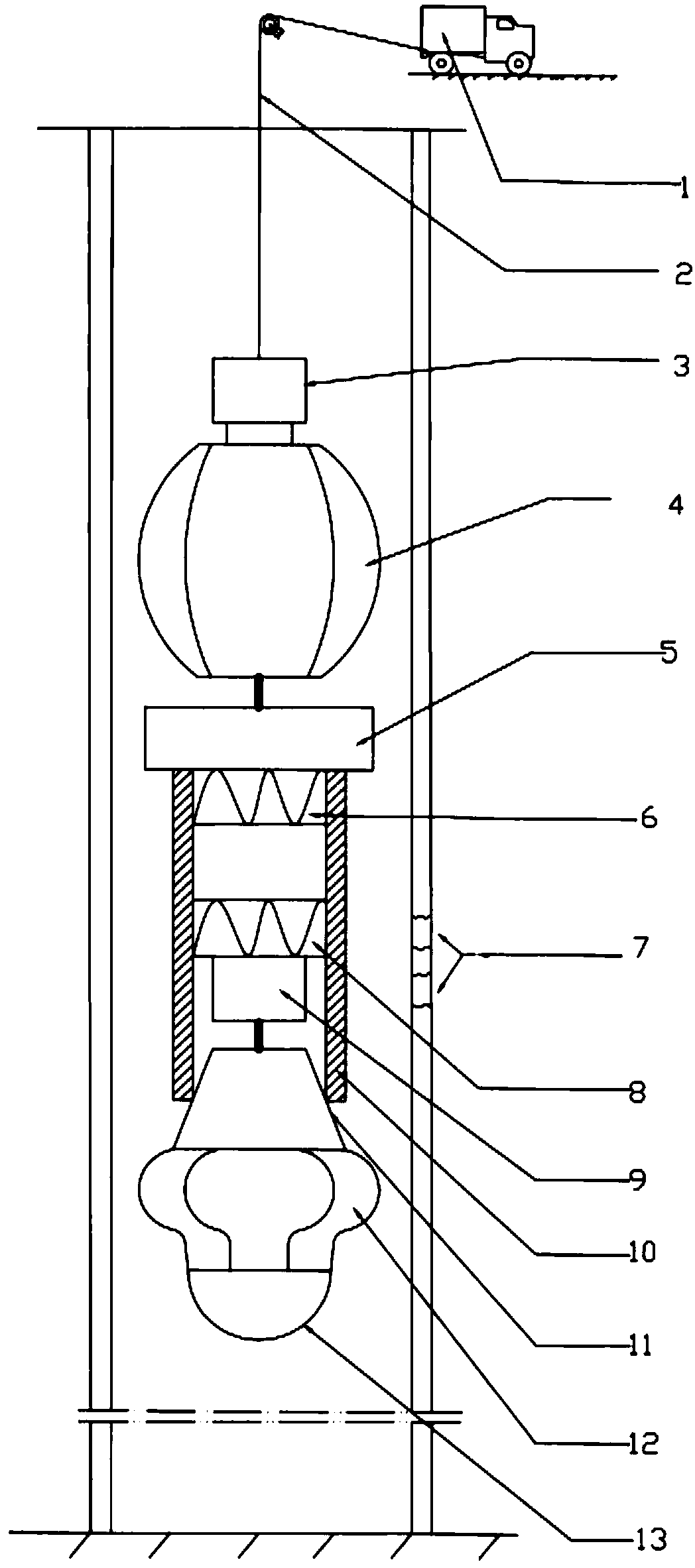

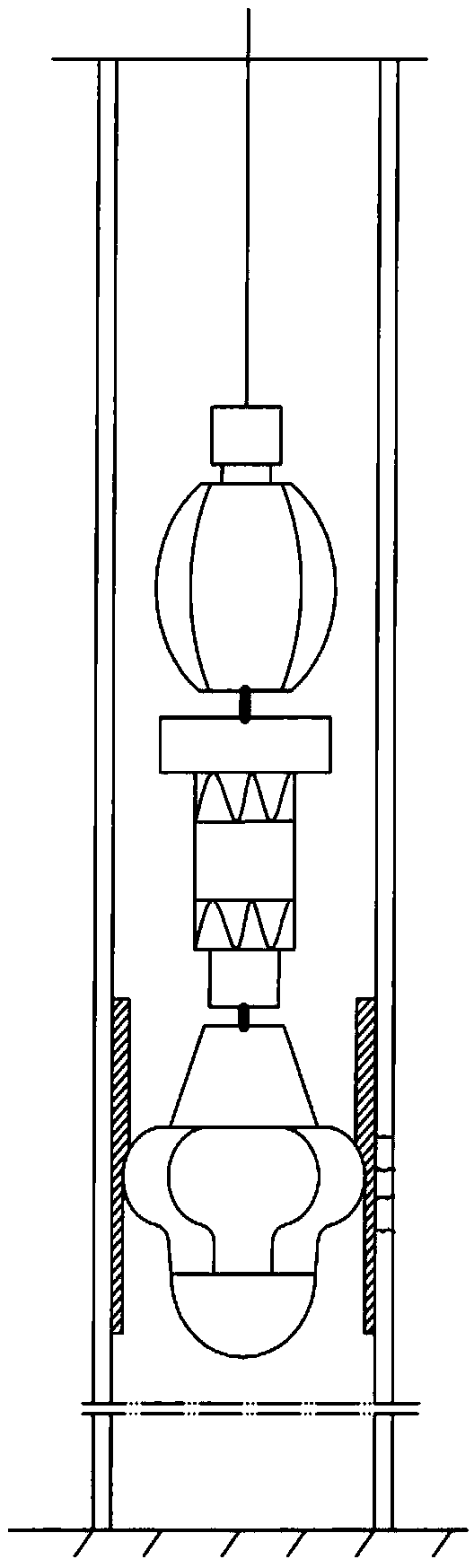

[0097] This embodiment provides an integrated device for composite material subsidy for casing damaged wells, and its structural schematic diagram is as follows figure 1 shown, from figure 1As can be seen in the figure, the device includes a cable setting tool, a cable heating tool and a hanging and throwing tool;

[0098] Wherein, the cable seating tool includes a centralizer 4, an electromagnetic expansion disc 5, a rigid expansion head 11, an elastic expansion head 12 and a plug 13;

[0099] The hanging and throwing tool includes an upper end hanging throwing tool, a middle end hanging throwing tool and a lower end hanging throwing tool;

[0100] One end of the upper end of the hanging tool is connected to the cable 2 through the upper safety joint 3, and the other end of the upper hanging tool is connected to the centralizer 4;

[0101] One end of the mid-end hanging tool is connected to the centralizer 4, and the other end is connected to the electromagnetic expansion d...

Embodiment 2

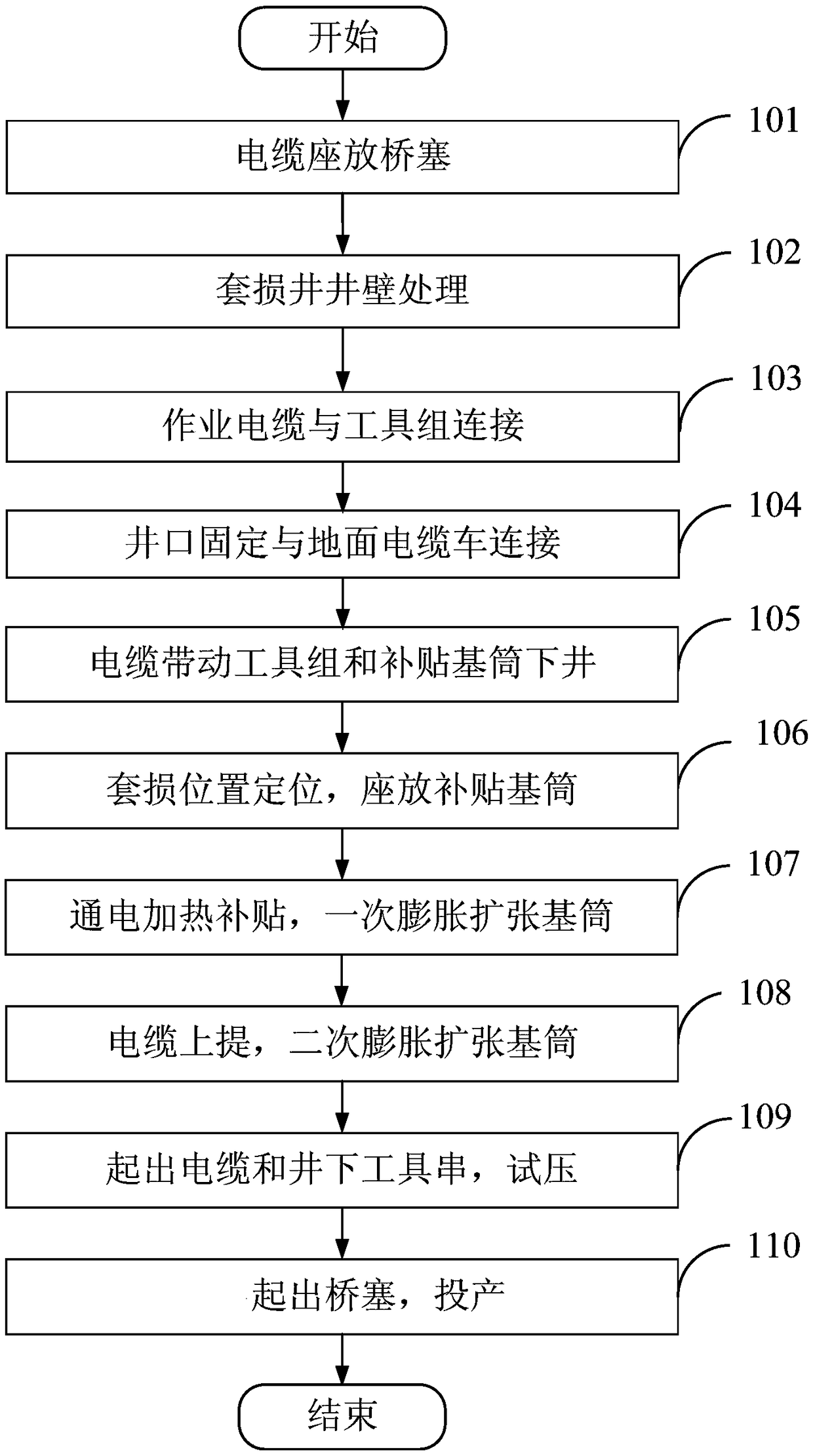

[0112] This embodiment provides a self-expanding subsidy method for oil well casing (with an outer diameter of ф93.9mm-ф450mm), which uses the integrated device (tool set ) to achieve, the specific process flow diagram of the method is as figure 2 shown, from figure 2 It can be seen that it includes the following specific steps,

[0113] Step 101: the cable seat is placed on the bridge plug, which specifically includes connecting the working cable to the cable bridge plug, lowering the cable bridge plug into a reliable position below the casing damage section in the well, and driving the bridge plug to set to separate the lower part of the well from the upper casing damage section;

[0114] Step 102: Scraper treatment, specifically including connecting the working tubing to a mechanical scraper, or connecting the cable to an electric scraper and running it into the well, and scraping the inner surface of the casing damage section to be subsidized to remove the attached corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap