Four-position stroke controller for part-turn valve electric device

A stroke controller and valve electric technology, which is applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems that the stroke setting value cannot be adjusted continuously, the manufacturing process is difficult, the structure is complicated, etc., and it can be checked and adjusted. The valve is intuitive, easy to operate, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

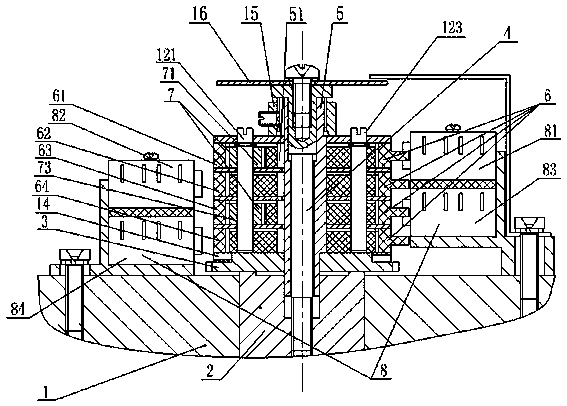

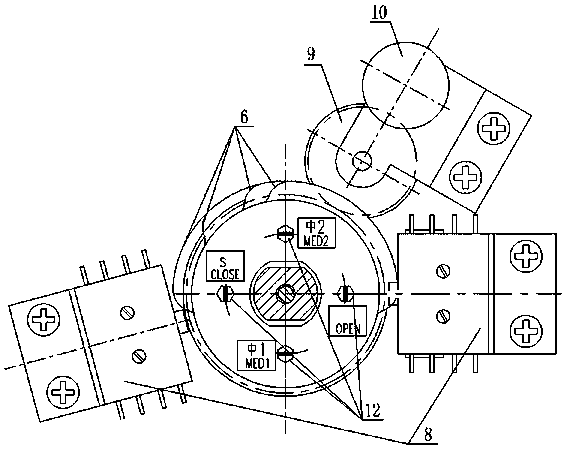

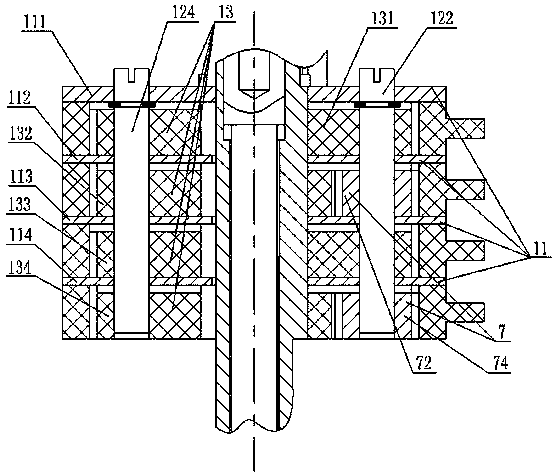

[0057] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0058] Such as Figure 1-4 The four-position stroke controller for the part-turn valve electric device shown includes box body 1, output shaft 2, degree opening gear 3, set screw 4, positioning sleeve 5, cam group 6, pinion group 7, micro-motion Switch group 8, transition gear 9, potentiometer 10, spacer group 11 and small shaft group 12;

[0059] The cam group 6 has a first cam 61 at the top, a second cam 62 at the second layer, a third cam 63 at the third layer and a fourth cam 64 at the bottom;

[0060] The pinion set 7 has a first pinion 71 , a second pinion 72 , a third pinion 73 and a fourth pinion 74 ;

[0061] The microswitch group 8 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com