Air conditioner anti-liquid return control method and air conditioner

A control method and technology for air conditioners, applied in heating and ventilation control systems, refrigerators, heating methods, etc., can solve problems such as compressor liquid hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In order to avoid liquid return to the compressor due to temperature and load changes during the operation of the air conditioner, resulting in liquid shock of the compressor and damage to the compressor, this embodiment provides an anti-liquid return control method for the air conditioner. 2 is heated to prevent liquid return; this embodiment is realized by passing the high-pressure gaseous refrigerant discharged from the compressor 2 into the heating tank 1 arranged at the bottom of the compressor 2, and using the high-pressure gaseous refrigerant to heat the bottom of the compressor 2 Anti back liquid.

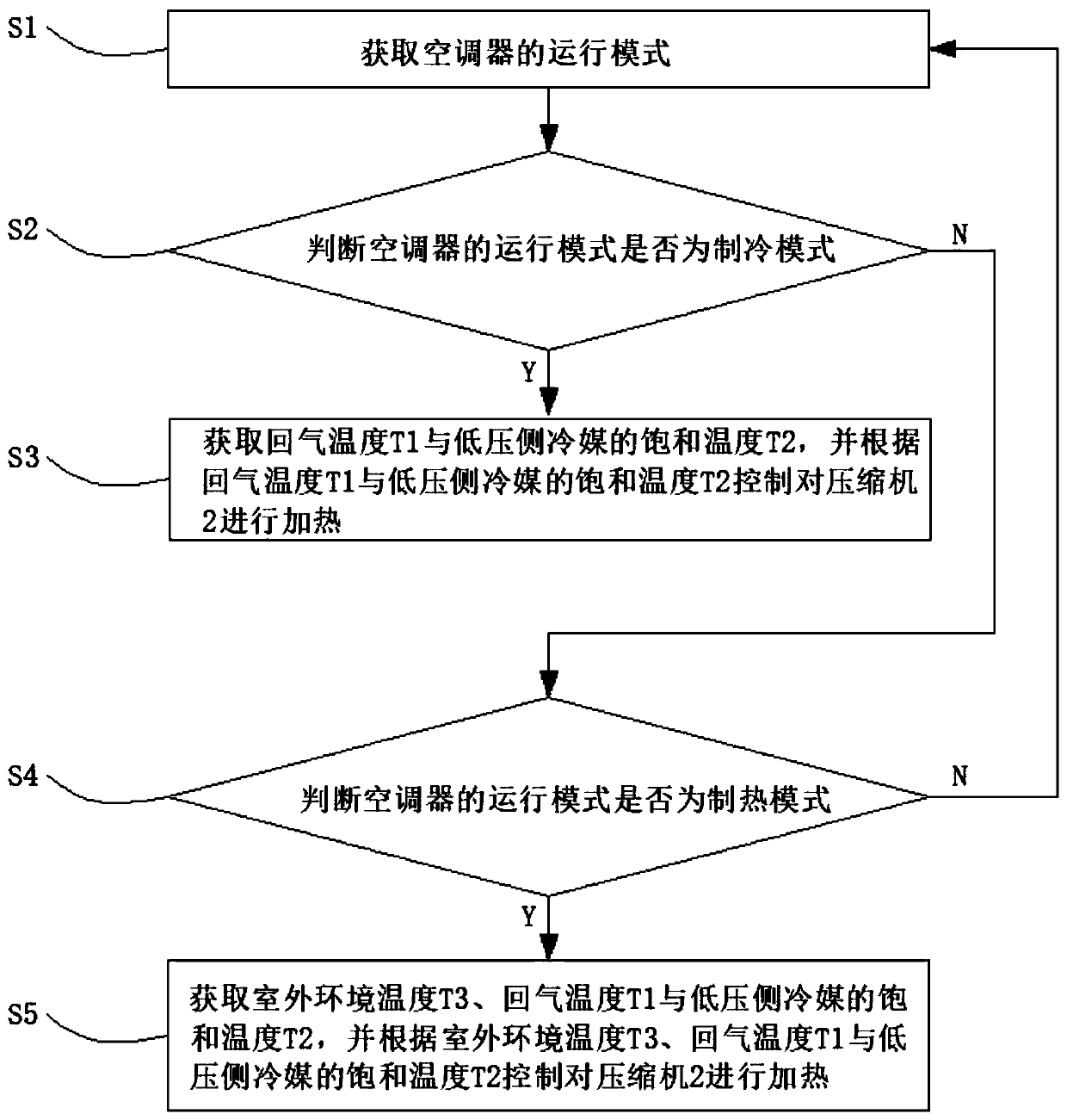

[0064] see figure 1 As shown, the air conditioner anti-liquid return control method provided in this embodiment includes:

[0065] S1: Obtain the operating mode of the air conditioner;

[0066] S2: Determine whether the operation mode of the air conditioner is cooling mode, if the operation mode of the air conditioner is cooling mode, then go to step S3, otherwise ...

Embodiment 2

[0078] The air conditioner in this embodiment includes a heating tank 1, and the heating tank 1 is arranged at the bottom of the compressor 2; a second exhaust pipeline 9 is connected between the air inlet of the heating tank 1 and the exhaust port of the compressor 2, A third exhaust pipeline 10 is connected between the exhaust port of the heating tank 1 and the condenser 4; the bottom of the compressor 2 is heated by passing the high-temperature and high-pressure refrigerant discharged from the compressor 2 into the heating tank 1 .

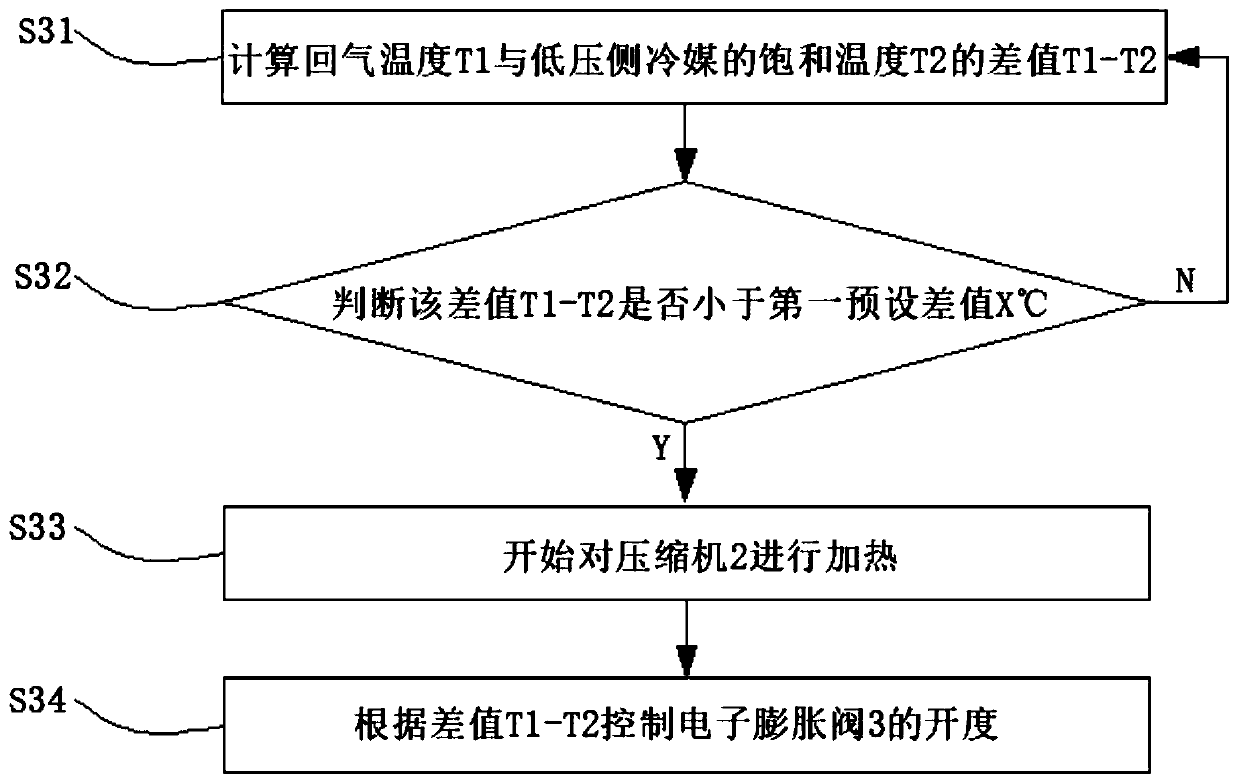

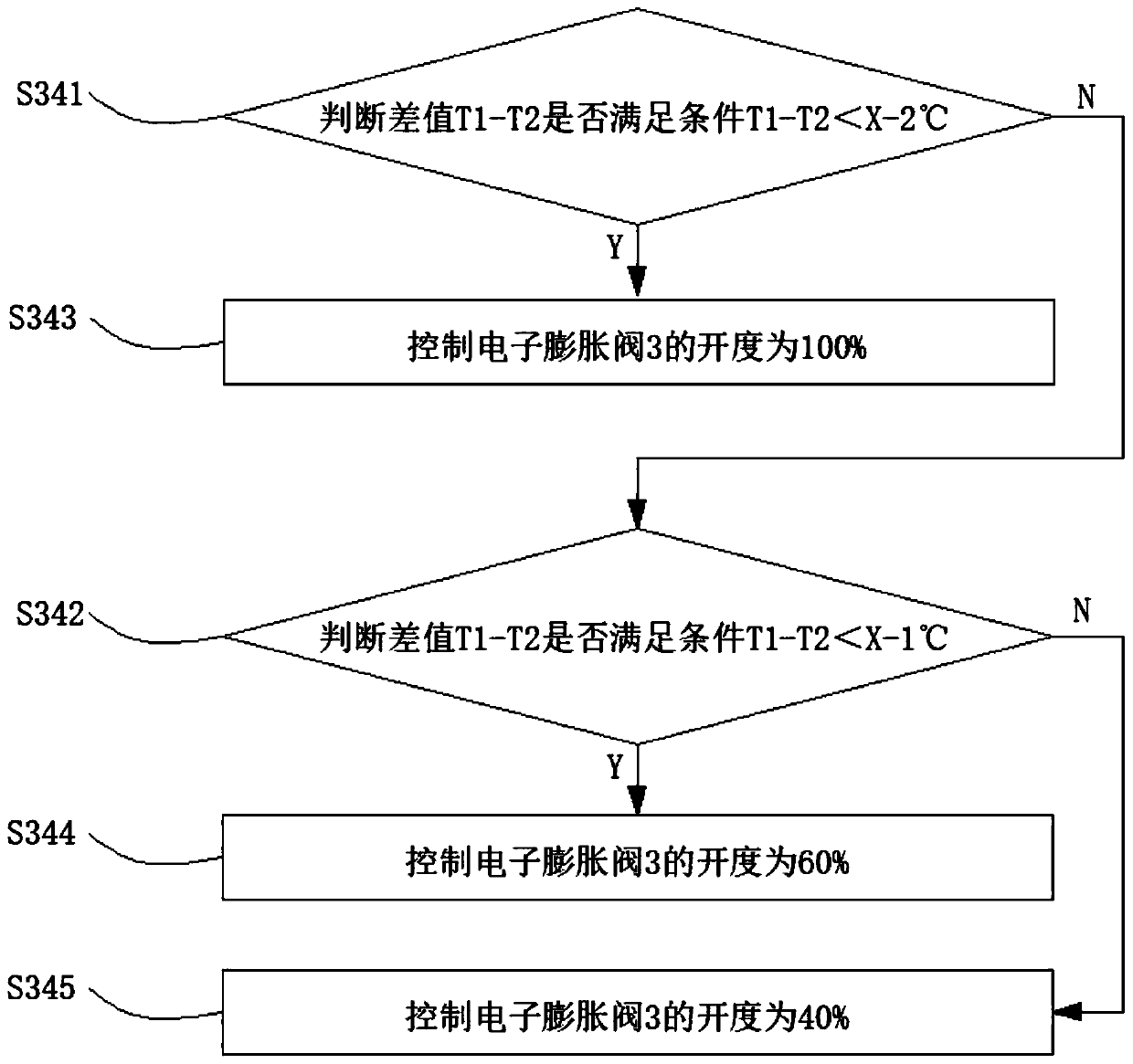

[0079] see figure 2 As shown, on the basis of Embodiment 1, controlling the heating of the compressor 2 according to the return air temperature T1 and the saturation temperature T2 of the low-pressure side refrigerant includes:

[0080] S31: Calculate the difference T1-T2 between the return air temperature T1 and the saturation temperature T2 of the low-pressure side refrigerant;

[0081] S32: Judging whether the difference T1-T2 is smaller t...

Embodiment 3

[0099] On the basis of embodiment 2, see Figure 4 As shown, in this embodiment, controlling the heating of the compressor 2 according to the outdoor ambient temperature T3, the return air temperature T1 and the saturation temperature T2 of the low-pressure side refrigerant includes:

[0100] S51: Judging whether the outdoor ambient temperature T3 is lower than the first preset temperature δ°C, if it is judged that the outdoor ambient temperature T3 is lower than the first preset temperature δ°C, go to step S52, otherwise go to step S53;

[0101] S52: Start heating the compressor 2, and control the opening of the electronic expansion valve 3 according to the outdoor ambient temperature T3;

[0102] S53: Judging whether the outdoor ambient temperature T3 is lower than the second preset temperature γ°C, if it is judged that the outdoor ambient temperature T3 is lower than the second preset temperature γ°C, go to step S54, otherwise go to step S51;

[0103] S54: Control the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com