Roller blind assembly for a vehicle body, and method for assembling the roller blind assembly

A technology for vehicles and roller blinds, applied in the field of roller blind components, can solve the problems of laborious manufacturing, significant cost, complex manufacturing logistics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

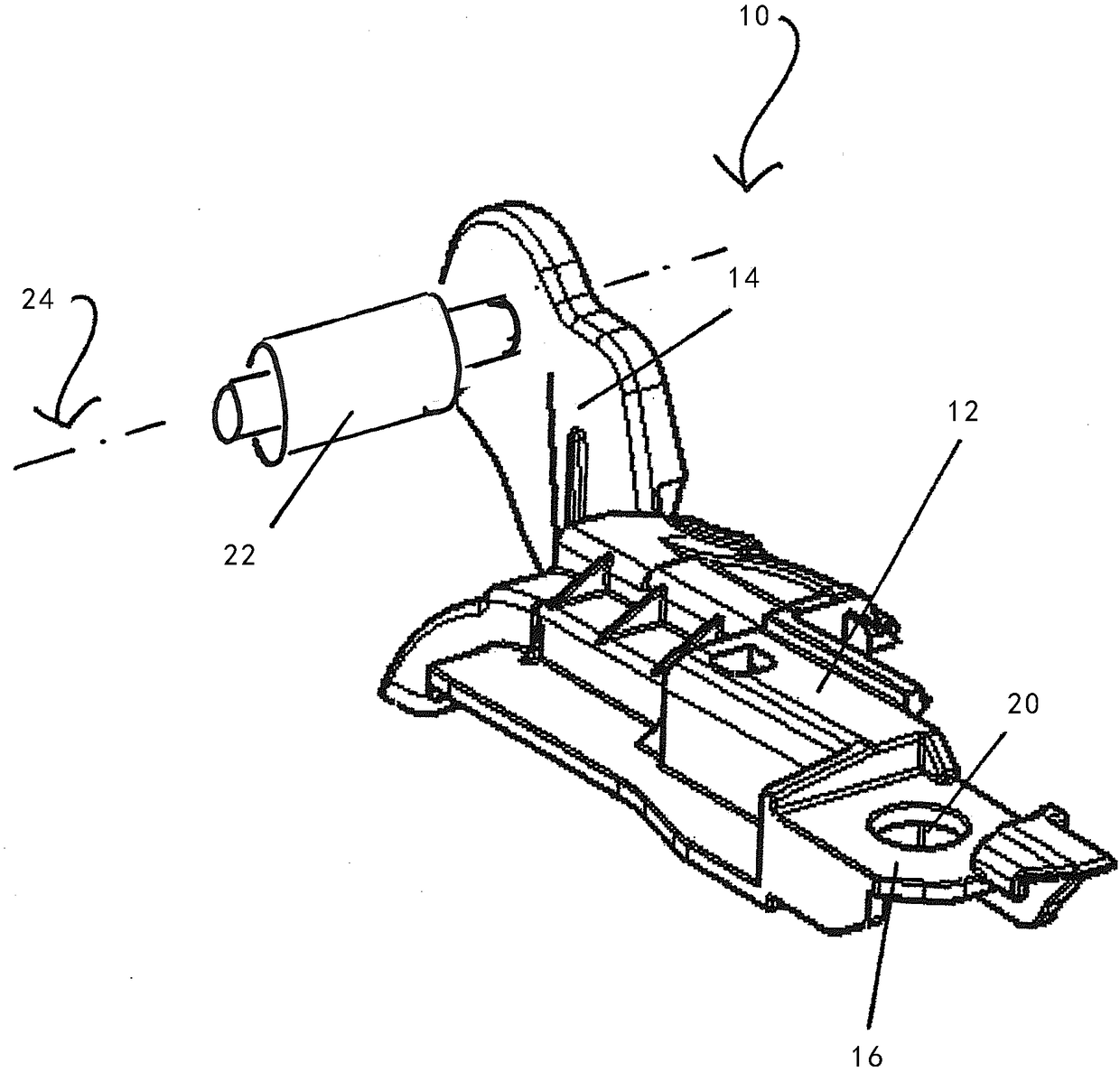

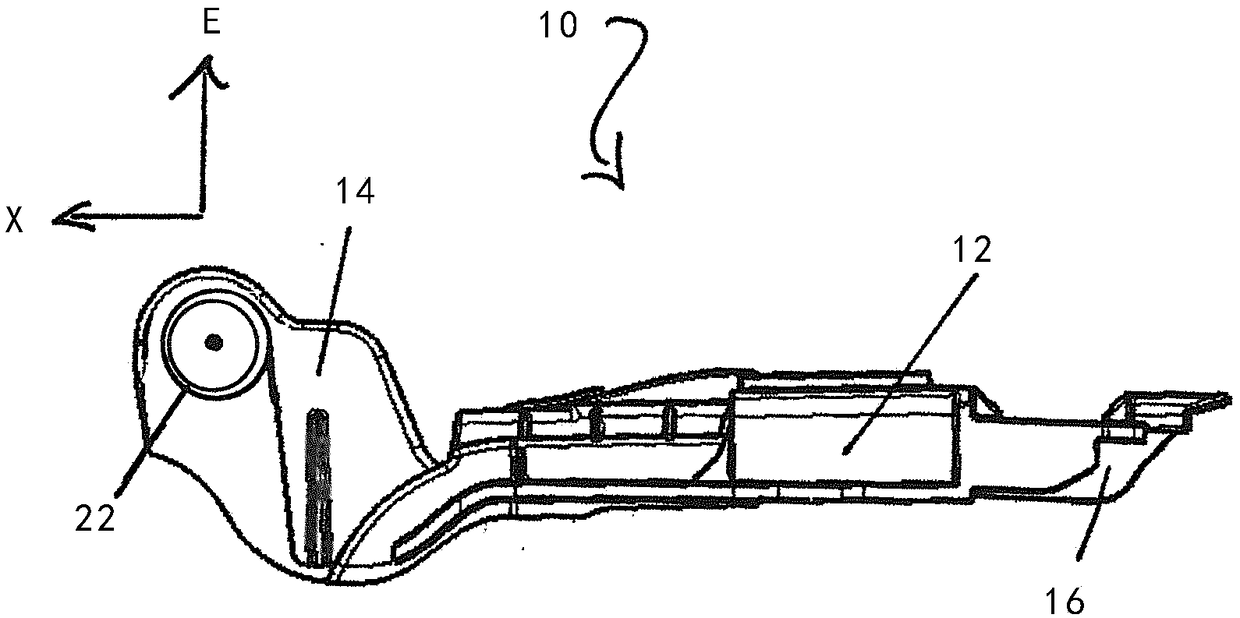

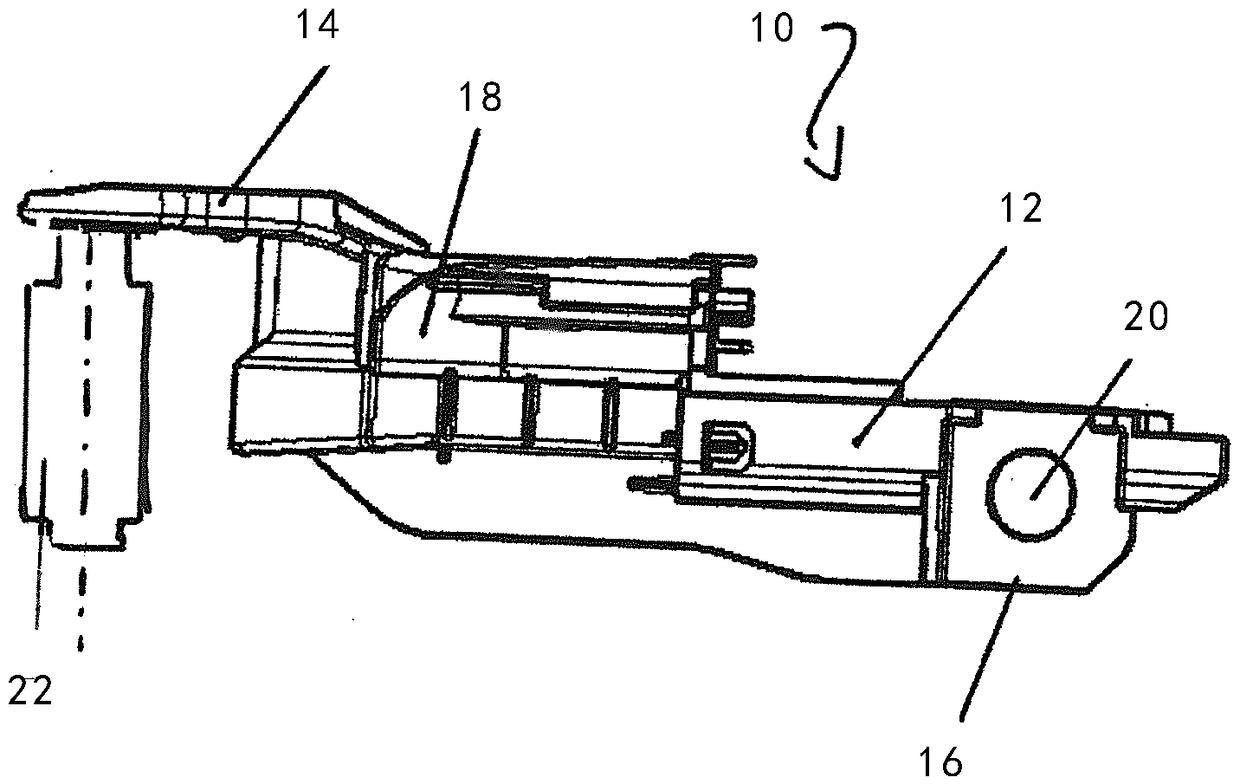

[0022] figure 1 A perspective view of a bearing element 10 according to the invention is shown. The support element 10 is used to support a winding reel, not shown in detail, for this purpose the support element 10 has a bearing pin 22 which is rotatably arranged on the support element 20 and is designed for engaging the winding reel in order to rotatably support the winding reel. Here, the bearing pin 22 can engage in a corresponding opening in the end face of the winding reel, and the bearing pin 22 is aligned substantially along the axis of rotation 24 of the winding reel, wherein the axis of rotation of the winding reel passes through the center of the bearing pin. Central axis extension.

[0023] According to the invention, the carrier element 10 has a standardized section 12 which is connected to a vehicle-specific section 14 . The carrier element 10 can be arranged by means of a standardized section 12 on a not shown guide rail or a likewise not shown frame. For thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com