Assembling machine for led lights with automatic ab silicone filling function

An LED lamp and assembly machine technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to realize automatic production and assembly, low production efficiency, large power consumption, etc., and achieve high production efficiency, short process, The effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

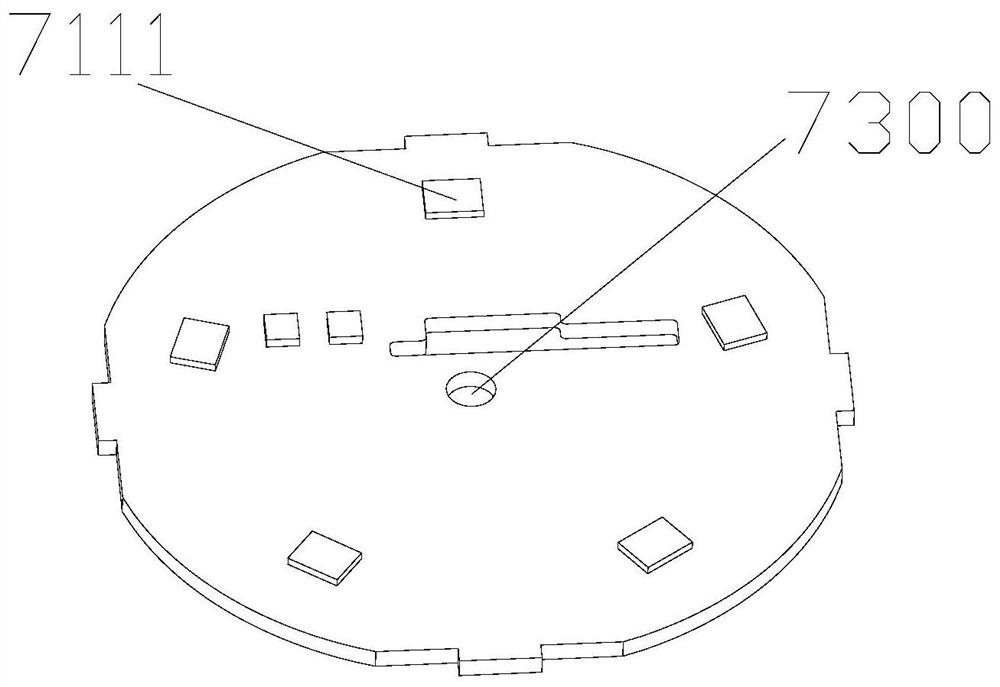

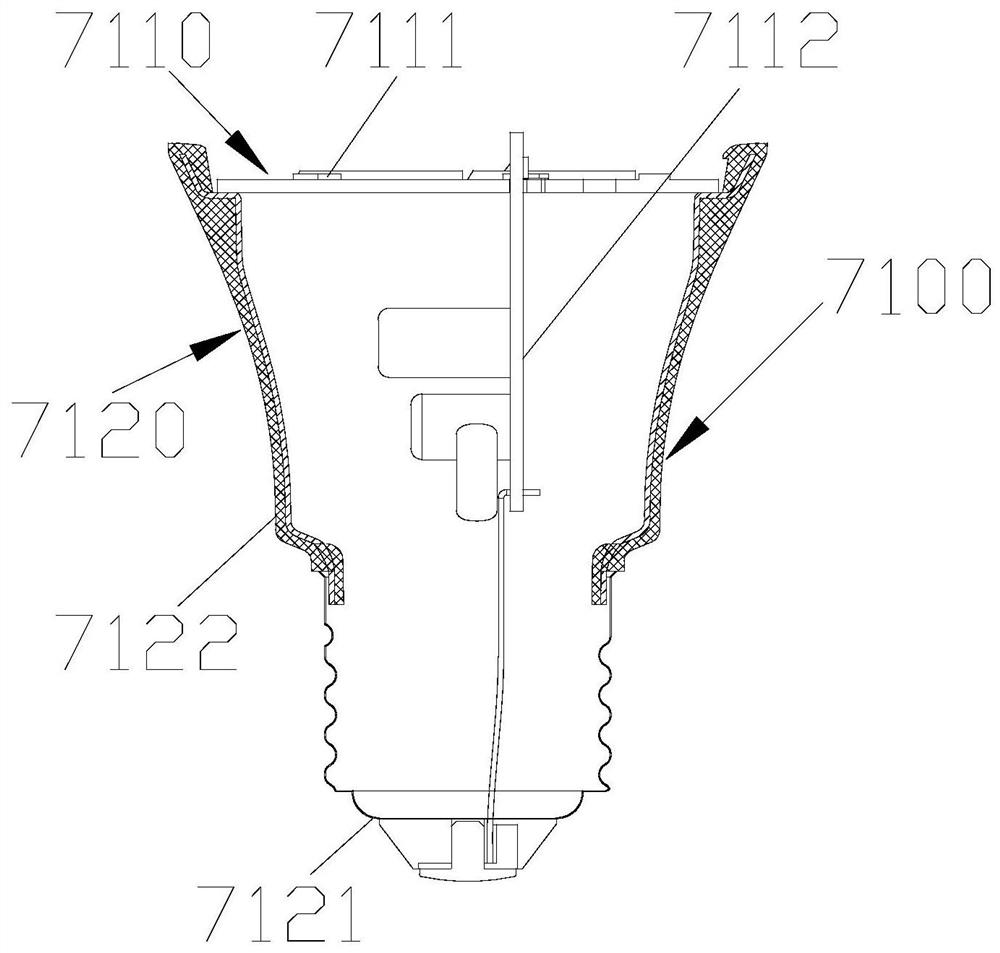

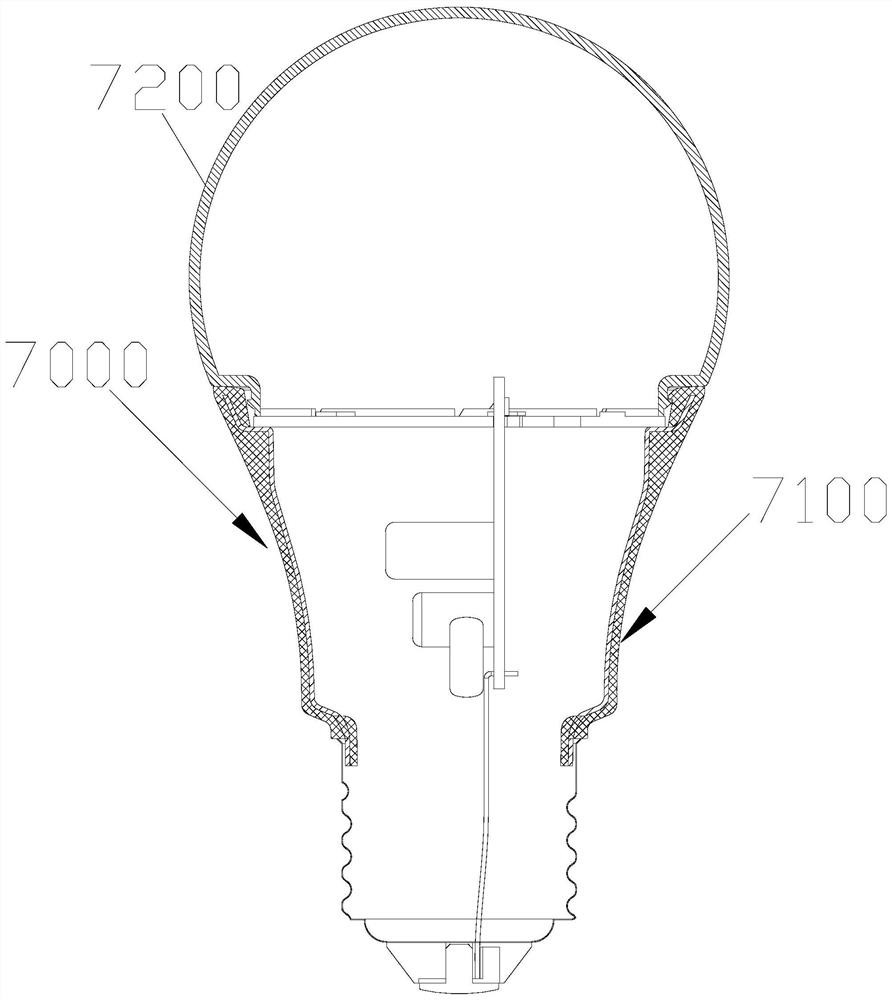

[0044] Such as Figure 1-6 As shown, the assembly method of this embodiment, wherein the LED lamp 7000 mainly includes a lamp holder 7121, a lamp housing 7122, a driving power supply 7112, a light source 7111, and a bulb 7200, the substrate of the light source 7111 is provided with a glue hole 7300, and the The assembly method of the LED lamp includes the following steps:

[0045] Step 1: Assemble the light source 7111 and the driving power supply 7112 into a photoelectric component 7110;

[0046] Step 2: Assemble the lamp holder 7121 and the lamp housing 7122 into a lamp holder lamp housing assembly 7120;

[0047]Step 3: Assemble the photoelectric component 7110 and the lamp housing component 7120 into the LED lamp body 7100, and then pour A and B glue into the interior of the LED lamp body 7100 through the glue hole 7300 on the substrate of the light source 7111;

[0048] Further, the third step is to heat the lamp cap 7121 of the LED lamp body 7100 while pouring AB glue i...

Embodiment 2

[0064] In this embodiment, the LED lamp body 7100 and the bulb 7200 can be assembled into a finished LED lamp 7000. The base plate of the light source 7111 is provided with a glue filling hole 7300. The assembly machine in this embodiment includes a turntable 1 and a turntable 1 The direction of rotation is sequentially set on the rotary table 1, the feeding mechanism 2, the glue applying mechanism 3, the glue filling mechanism 4, the bulb 7200 installation mechanism 5 and the unloading mechanism 6;

[0065] The turntable 1 is provided with a turntable 11 that can rotate intermittently, and the turntable 11 is provided with a plurality of processing stations 111 for placing the LED lamp main body 7100; Place the LED lamp main body 7100 on the adjacent processing station 111; the gluing mechanism 3 will smear packaging glue around the upper surface of the LED lamp main body 7100 when the turntable 11 is in a stationary period of rotation; the gluing mechanism 4 When the turntab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com