Circulating spraying cooling system for vertical type methyl alcohol storage tank

A technology of cyclic spraying and methanol, applied in tank trucks, liquid distribution, containers, etc., can solve the problems of high production cost, serious evaporation, loss of raw materials, etc., and achieve the effect of reducing waste, improving cooling effect and high economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

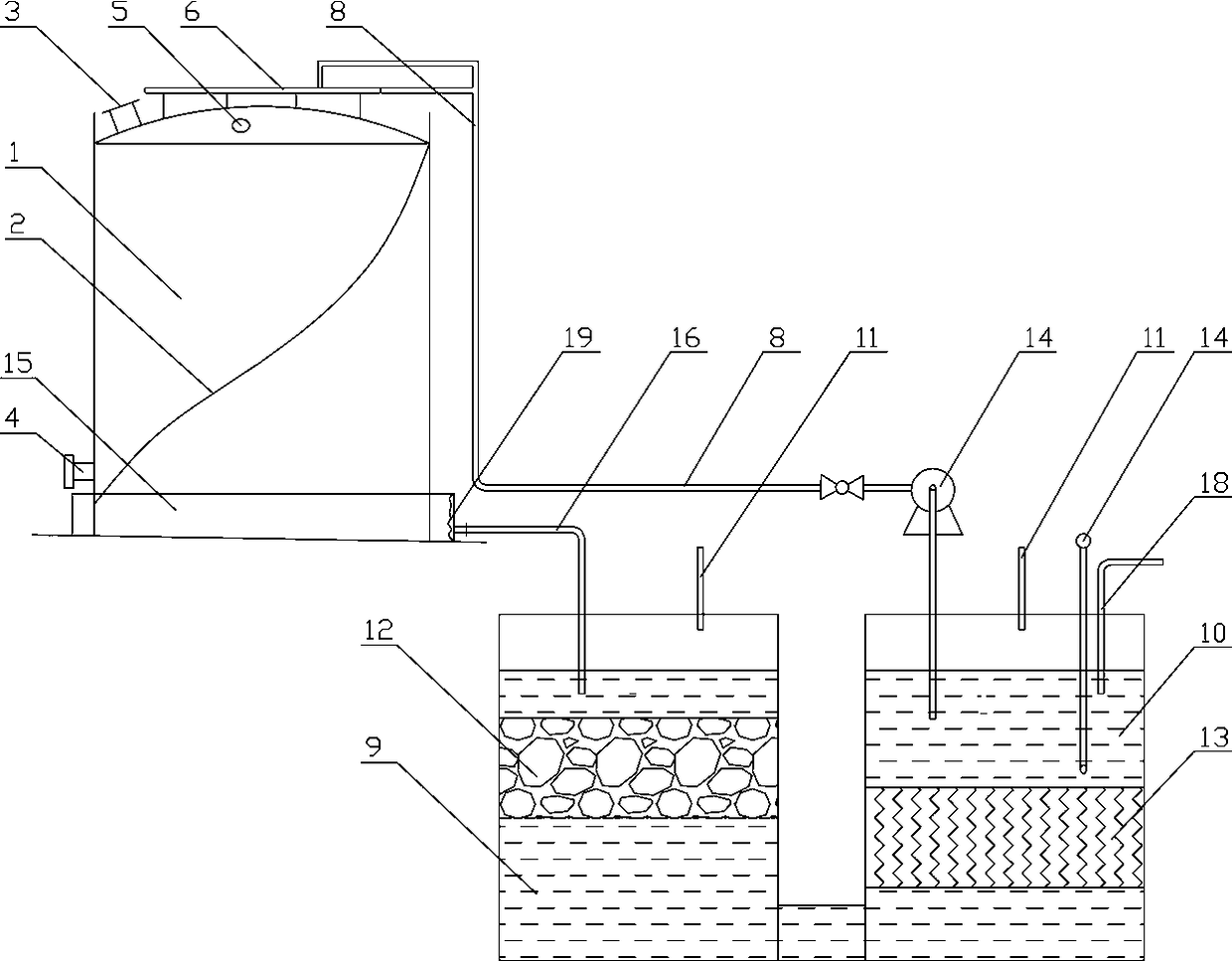

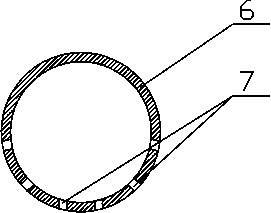

[0018] See Figure 1-2 The technical scheme of the present invention is: a vertical methanol storage tank circulating spray cooling system, which has a vertical methanol storage tank 1, and a spiral staircase 2 is provided between the bottom of the methanol storage tank 1 and the top of the methanol storage tank. The top of the storage tank 1 is provided with a feeding port 3 and a breathing valve 4, and the bottom of the tank is provided with a discharge port 5. In particular, the top of the methanol storage tank 1 is equipped with a cooling water spray device and a cooling water spray device The inner and outer rings of spray pipes 6 are distributed in a ring shape. The inner and outer sides of the inner and outer rings of spray pipes 6 are provided with a number of water spray holes 7 on both sides and at the bottom. The inner and outer rings of spray pipes 6 are connected to the water supply main 8; A circulating water storage tank A 9 and a circulating water storage tank B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com