Airborne mist spraying cooling system using radiant plate cooling circulation water

A technology for cooling circulating water and spray cooling, which is applied to machines, refrigerators, and refrigeration components that use refrigerant evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

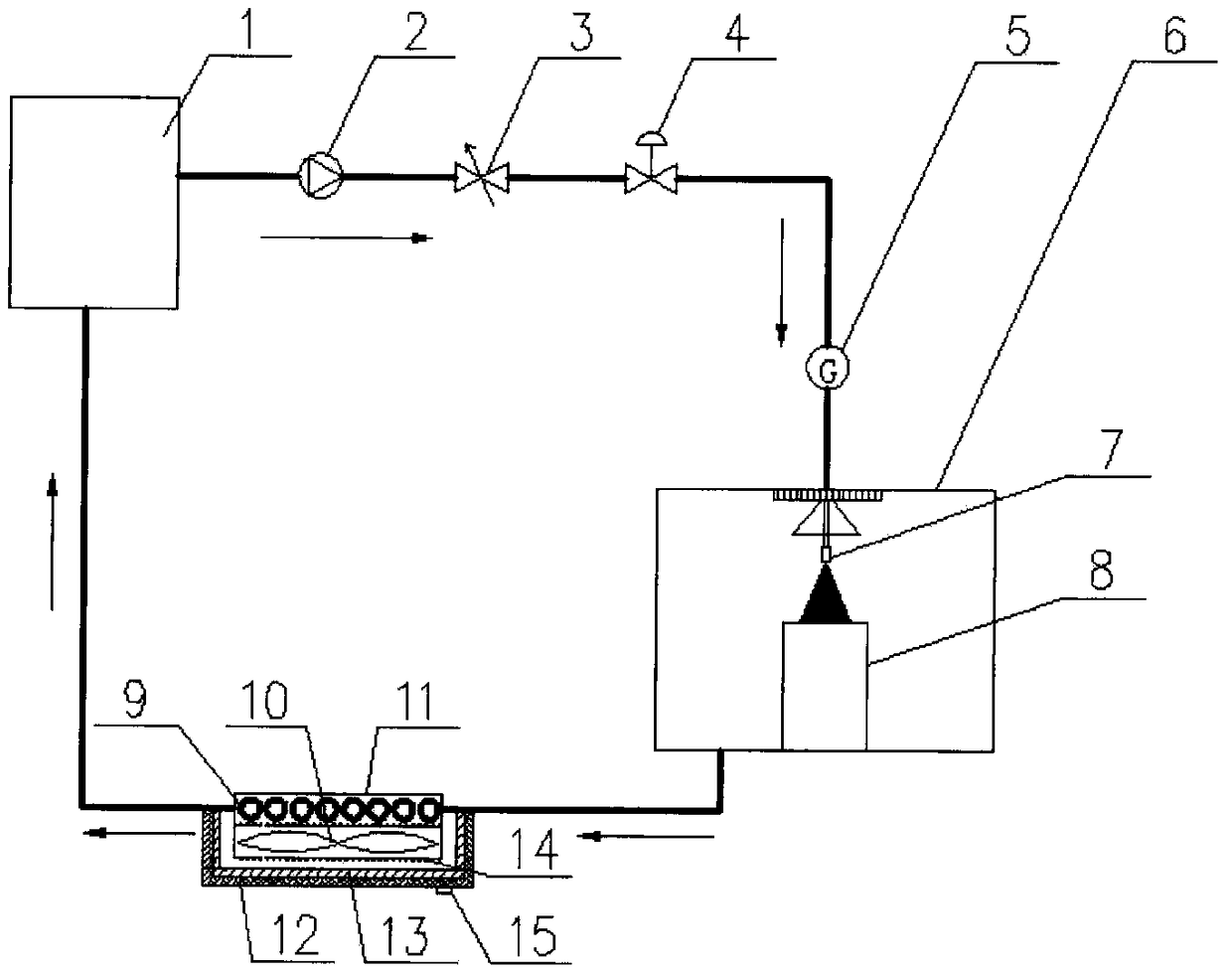

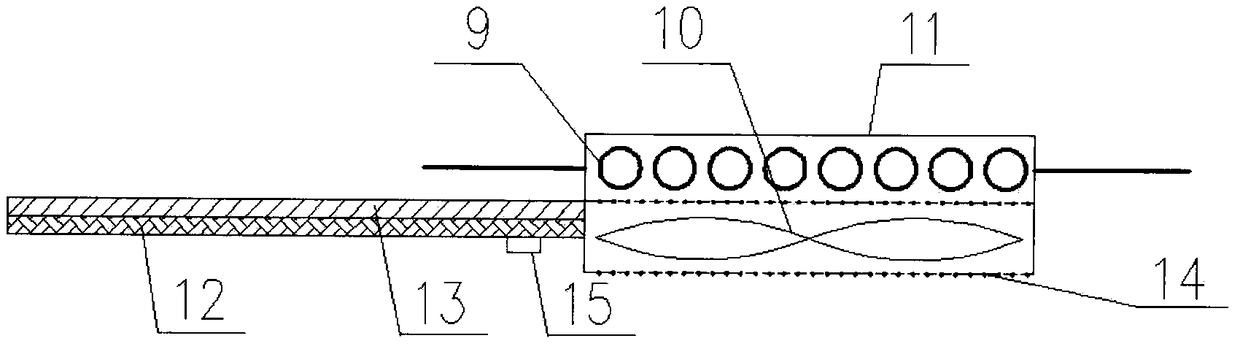

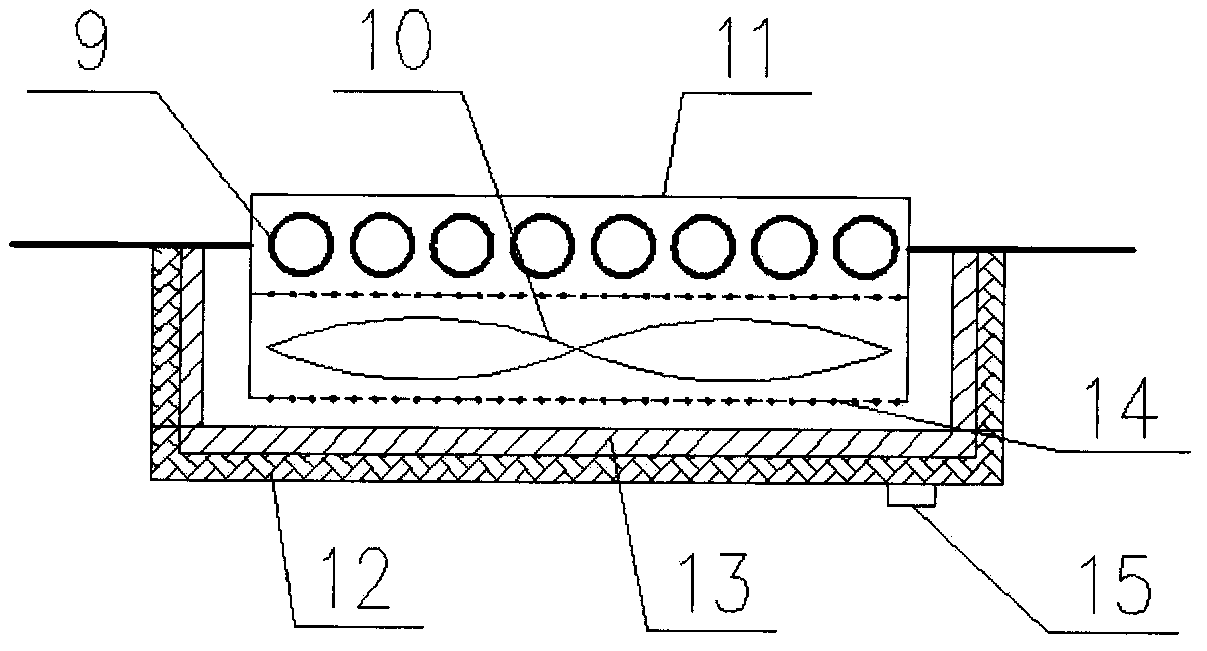

[0023] Such as figure 1 As shown, an airborne spray cooling system using radiant panels to cool circulating water mainly includes a water tank 1, a water pump 2, a flow regulating valve 3, a stop valve 4, a flow meter 5, a spray chamber 6, a nozzle 7, a surface to be cooled 8, Copper tube 9, fan 10, radiant plate heat exchanger 11, sealing layer 12, heat preservation layer 13, plastic support grid 14, shrink switch 15 of heat preservation device.

[0024] Before the aircraft takes off, the running time of the spray cooling system is obtained according to the flight time of the aircraft and the required cooling time of the equipment, and a certain amount of water is filled in the water tank 1 according to the running time. At this time, the flow regulating valve 3 and the shut-off valve 4 are both in the closed state.

[0025] After the aircraft takes off, when the electronic equipment or other surfaces need to be cooled, the shut-off valve 4 is opened, the water flow is adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com