Mechanical mounting and detaching tool and mounting and detaching method with same

A disassembly tool and mechanical technology, which is applied in the installation and disassembly field of installation tools and track fasteners, can solve the problems of unstable pressure, failure to maintain pressure, and reduce the service life of the hydraulic system, so as to increase the service life and avoid insufficient clamping force. Stabilize and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

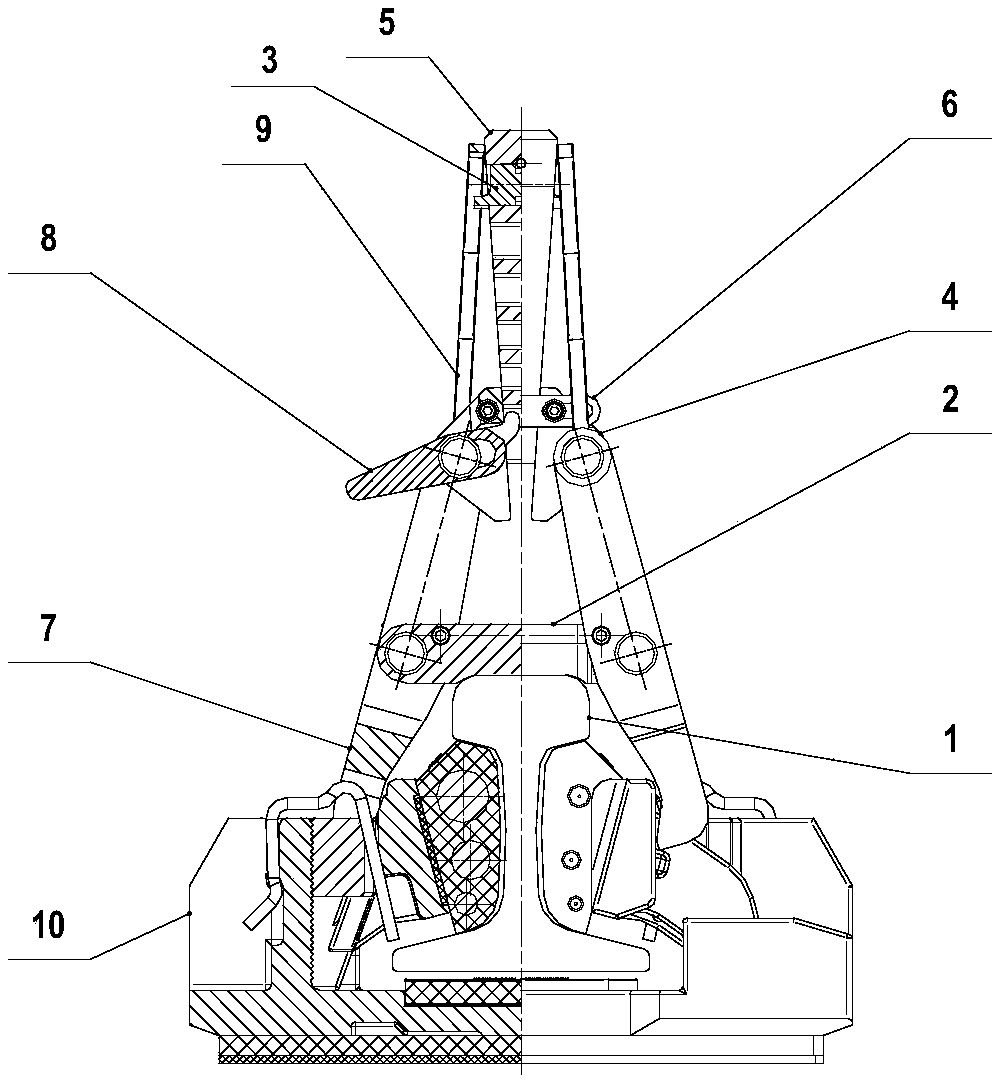

[0038] Such as figure 1 As shown, the present invention discloses a mechanical installation and disassembly tool, which includes two forks 7, and a spreading device is arranged at the upper ends of the two forks 7, and the spreading device can connect the forks 7 and the forks under the action of external force. The floating rail fastener 10 is tightly attached or separated, and then the floating rail fastener 10 is installed or disassembled.

[0039] Preferably, a connecting frame 2 is arranged between the two clamping forks 7 , the two ends of the connecting frame 2 are hingedly connected with the clamping forks 7 , and the lower part of the clamping forks 7 is arranged in cooperation with the floating rail fastener 10 .

[0040] Preferably, the spreading device includes a slanting block 4 arranged on the upper end of the fork 7, the slanting block 4 is hingedly fixed to the fork 7, and a limiting rod 6 is set between the two slanting blocks 4, so that Both ends of the limi...

Embodiment 2

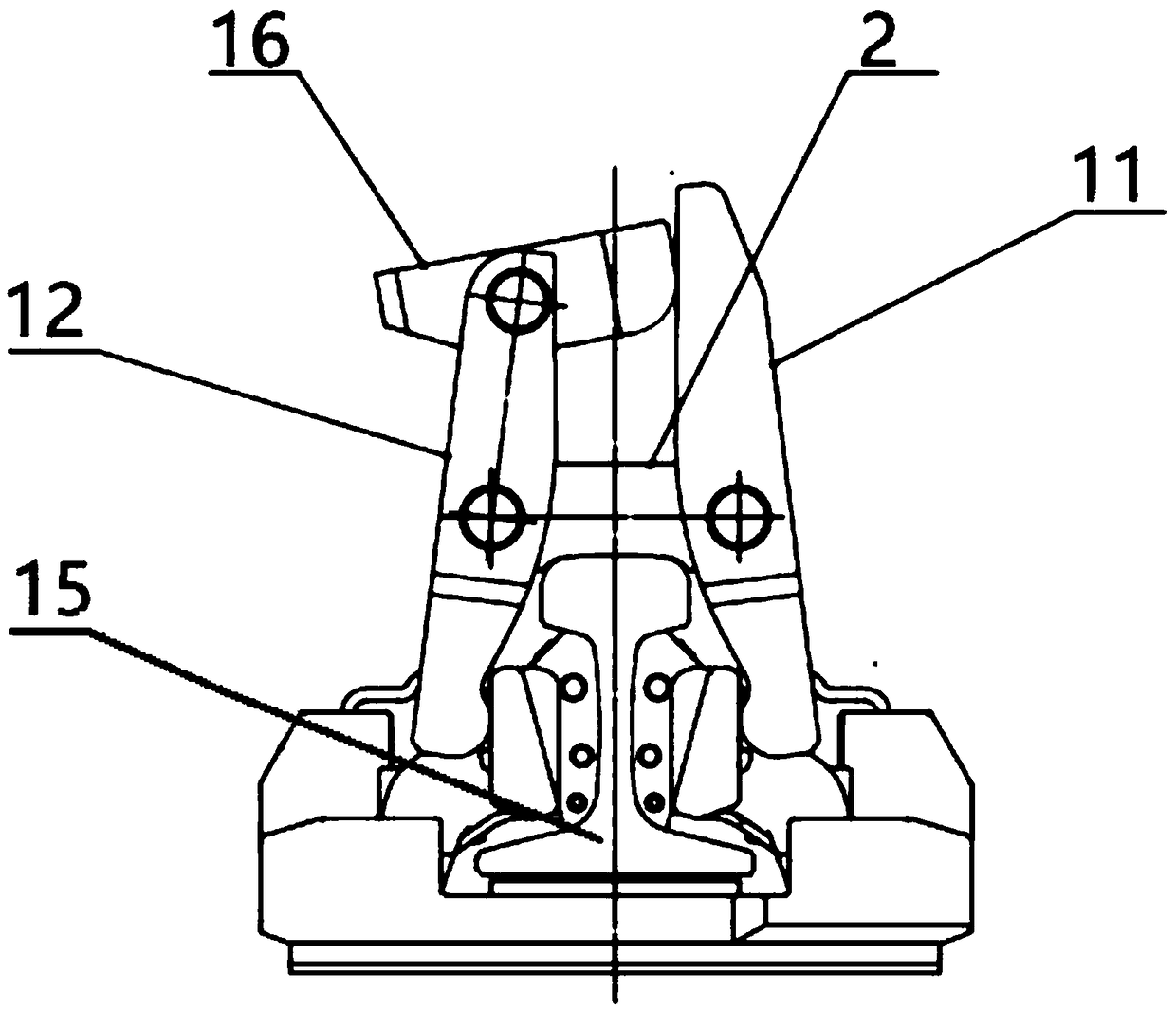

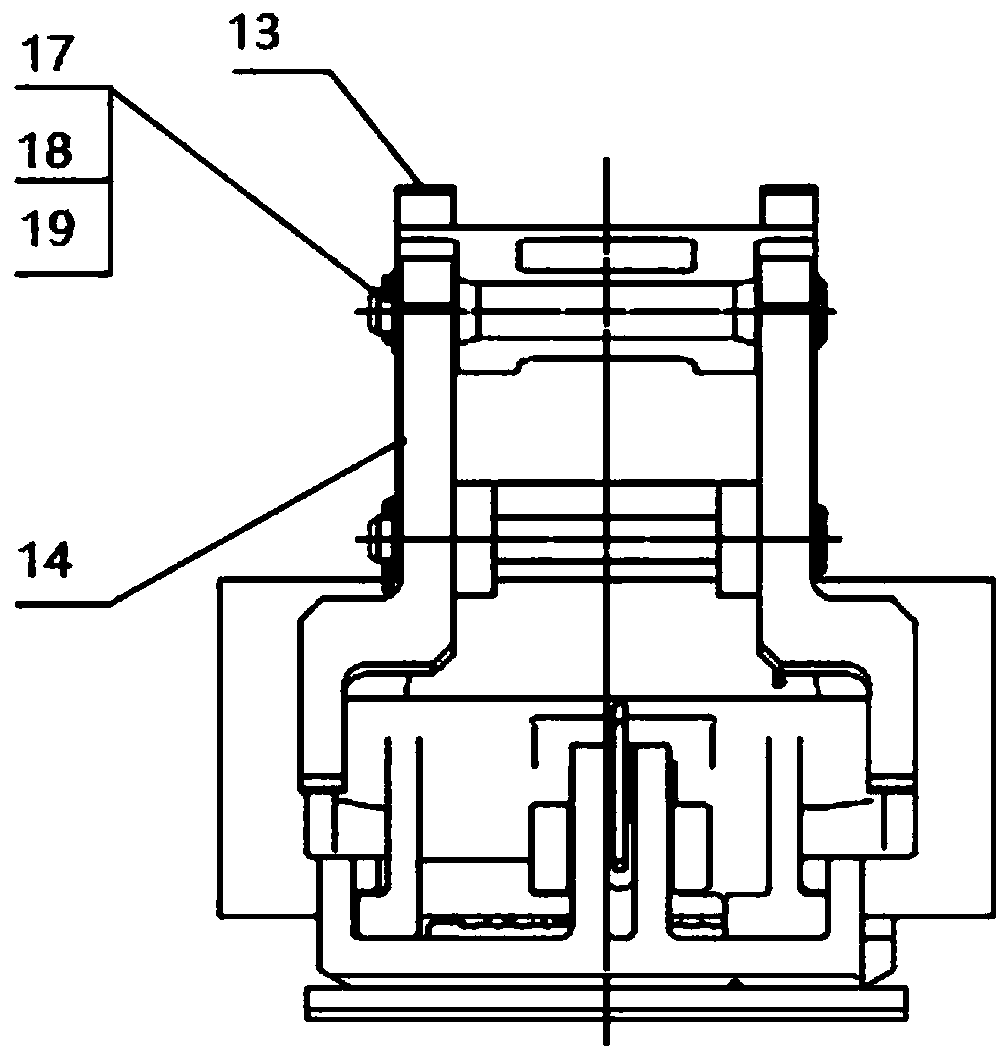

[0063] Such as Figure 2-4 As shown, the mechanical installation and removal tool of the present invention includes a brace device, and a first connecting rod 17 is arranged between the brace devices, and the brace device includes a first brace 11, a second brace 12 , the third strut 13 and the fourth strut 14, the first strut 11, the second strut 12, the third strut 13 and the fourth strut 14 pass through the second connecting rod 18, the third connecting rod 19 Two clamping forks 7 are formed, the lower part of the clamping forks 7 is set in cooperation with the floating rail fastener 10, and a spreading device is arranged on the upper ends of the two clamping forks 7, and the spreading device can connect the clamping forks 7 and the floating rail under the action of external force. The rail fastener 10 is attached or separated.

[0064] As an example of the present invention, the described stretching device is a hammer support block 16, the hammer support block 16 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com