Comprehensive pre-pressing method and device for tied-arch bridge cross beam suspension construction beam lattice system

A beam-lattice system and tie-arch bridge technology, applied in bridges, arch bridges, bridge forms, etc., can solve problems such as the inability to use step-by-step preloading, easy to be restricted by traffic conditions or other environmental conditions under the bridge, and achieve heap load stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

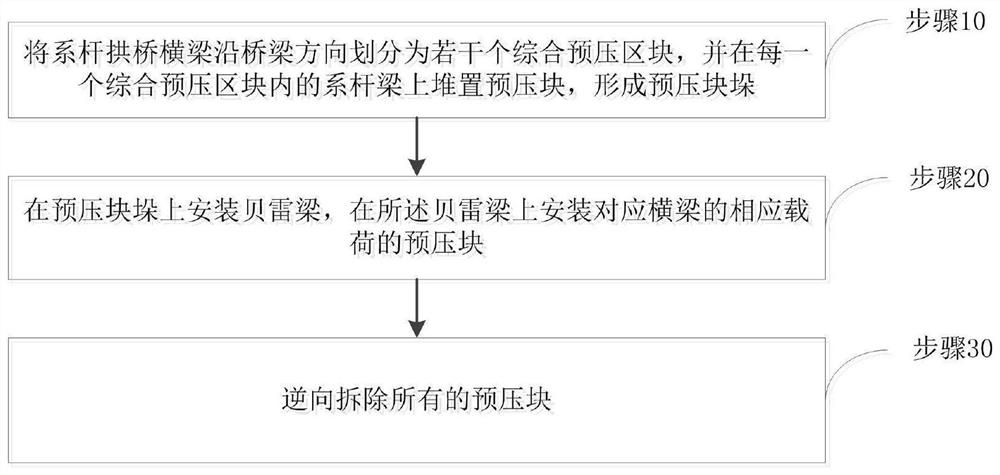

[0023] Such as figure 1 and 2 As shown, the embodiment of the present invention provides a comprehensive preloading method for the beam lattice system of the beam suspension construction of the tied arch bridge, comprising the following steps:

[0024] Step 10: Divide the tie girder of the tied arch bridge into several comprehensive preloaded blocks along the direction of the bridge, and stack preloaded blocks on the tie beams in each comprehensive preloaded block to form a stack of preloaded blocks .

[0025] The tie beam is composed of several tie beam supports. In order to facilitate the stacking of preloaded blocks on the tie beam, the tie beam is first divided into several comprehensive preload blocks along the direction of the bridge. In each comprehensive preload area On the tie beams in the block, the preloaded blocks are equivalently stacked according to the corresponding load or the preloaded blocks are stacked overloaded according to the specifications. The code ...

Embodiment 2

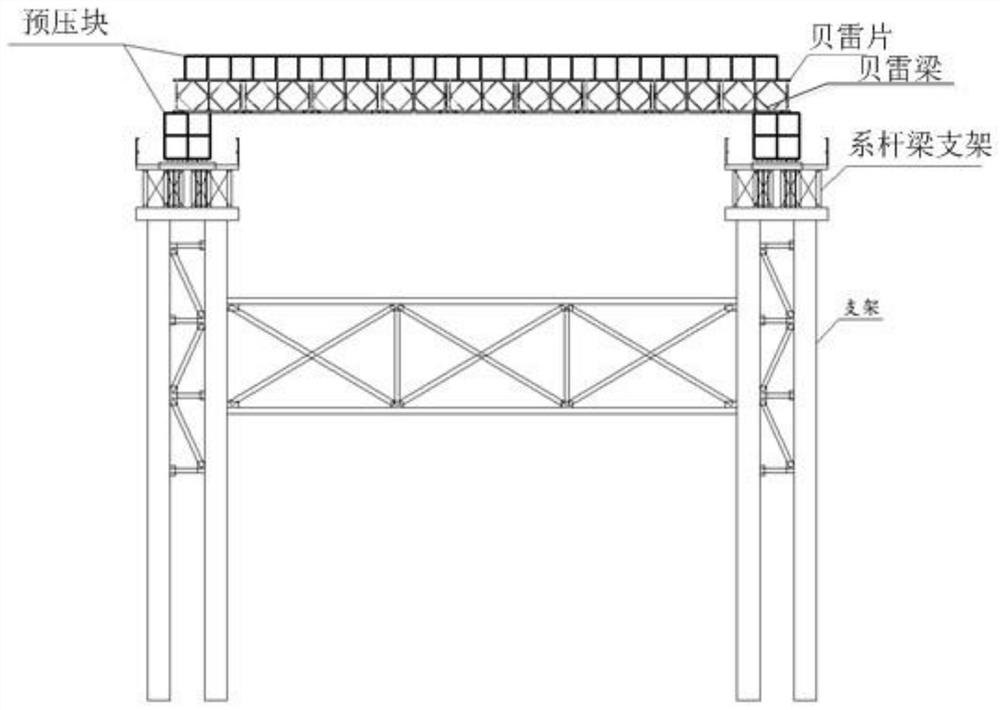

[0034] The present invention also provides a comprehensive preloading device for the beam lattice system of the beam suspension construction of the tied arch bridge, such as figure 2 As shown, it includes the bracket, the tie beam on the bracket, the pre-compression block and the Bailey beam installed on the pre-compression block stack. The tie beam is divided into several comprehensive pre-compression blocks along the direction of the bridge. The pre-compression block The stack of briquetting blocks is formed by a number of pre-compressing blocks stacked on the tie beam in each comprehensive pre-compressing block; pre-compressing blocks corresponding to the corresponding load of the beam are also installed on the Bailey beam.

[0035] Preferably, the pre-compacted block is a concrete cube pre-compacted block.

[0036] Preferably, the volume of the concrete cube pre-pressed block is 1m 3 .

[0037] The embodiment of the present invention corresponds to the above-mentioned c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com