Rocket engine main thrust vacuum field calibration system

A rocket engine and on-site calibration technology, which is applied to the calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc., can solve problems such as the inability to strictly determine the relationship between the performance parameters of the engine and the complexity of the rocket engine’s working process. , to achieve the effect of fast loading speed, small workload and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

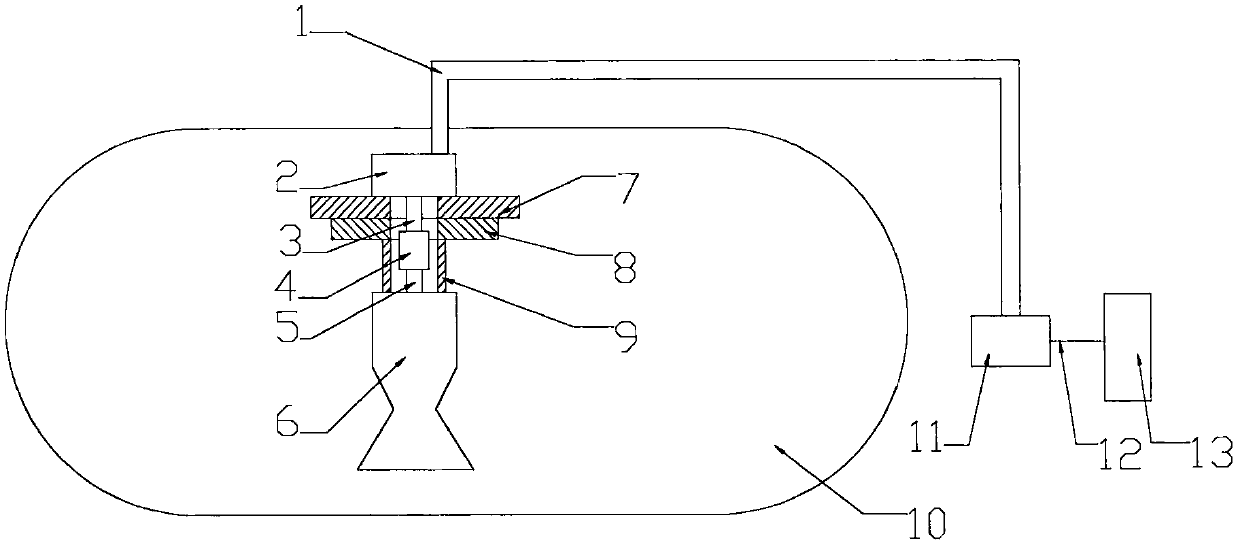

[0022] attached by figure 1 Given, the present invention is

[0023] The rocket engine main thrust vacuum on-site calibration system consists of the following parts: booster pipeline (1), hydraulic cylinder (2), loading rod A (3), standard force sensor (4), loading rod B (5), rocket engine ( 6), loading flange (7), main thrust sensor (8), adapter frame (9), vacuum chamber (10), servo motor (11), control cable (12), controller (13). Wherein the pressurized pipeline (1) is connected with the hydraulic cylinder (2) and is used for loading the hydraulic cylinder (2). The hydraulic cylinder (2) is connected to the loading rod A (3) and the loading flange (7), the loading rod A (3) is connected to the standard force sensor (4), and the standard force sensor (4) is connected to the loading rod B (5) connected, the loading rod B (5) is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com