Constant-pressure deep shale gas volume fracturing method

A volume fracturing and shale gas technology, which is applied in the field of oil and gas field exploration and development, can solve the problems of reduced conductivity, failure to realize volume fractures, and reduction of the geometric size of main fractures, and achieve enhanced shaping characteristics, which is conducive to popularization and application , Improve the success rate of fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

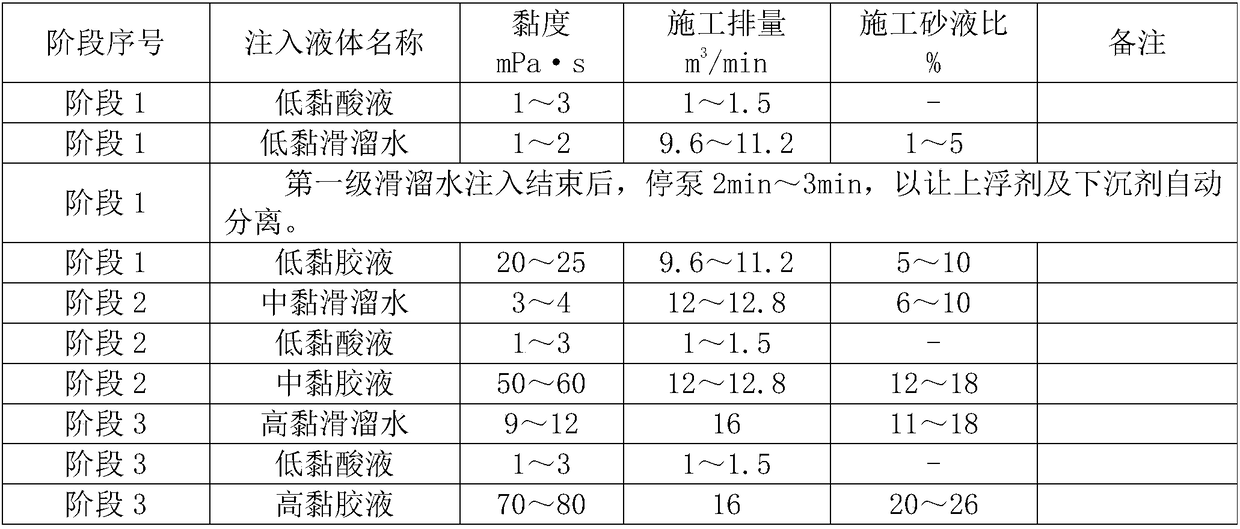

Embodiment 1

[0092]X exploration well, the present invention is further described in detail, and this well is a typical deep layer normal pressure shale gas well:

[0093] (1) Evaluation of key reservoir characteristic parameters

[0094] Using methods such as mud logging, well logging, and core analysis, the well was evaluated for lithology, mineral composition analysis, sensitivity, physical properties, rock mechanics, three-dimensional in-situ stress, and development of natural fractures.

[0095] (2) Compressibility evaluation and perforation position determination

[0096] Based on the evaluation of geological parameters in (1), the fine compressibility index evaluation of the well along the horizontal wellbore direction was carried out, and the best perforation position was determined.

[0097] (3) Perforation operation

[0098] The spiral perforation method is adopted, the length of each perforation cluster is 1m, the perforation density is 16 holes / m, the phase angle is 60°, and ...

Embodiment 2

[0111] Well Y,

[0112] (1) Evaluation of key reservoir characteristic parameters

[0113] Using methods such as mud logging, well logging, and core analysis, the well was evaluated for lithology, mineral composition analysis, sensitivity, physical properties, rock mechanics, three-dimensional in-situ stress, and development of natural fractures.

[0114] (2) Compressibility evaluation and perforation position determination

[0115] Based on the evaluation of geological parameters in (1), the fine compressibility index evaluation of the well along the horizontal wellbore direction was carried out, and the best perforation position was determined.

[0116] (3) Perforation operation

[0117] The spiral perforation method is adopted, the length of each perforation cluster is 1.5m, the perforation density is 16 holes / m, the phase angle is 60°, and the hole diameter is 10.5mm.

[0118] (4) Acid pretreatment operation

[0119] Displacement 1.0m 3 Under the condition of / min, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com