Pneumatic feeding machine

A bait feeder and pneumatic technology, applied in climate change adaptation, fish farming, application, etc., can solve the problems of poor feeding effect, adverse effects on hand joints, and large workload, so as to increase the range of feeding, and increase the range of feeding. The effect of wide feeding range and preventing bait accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

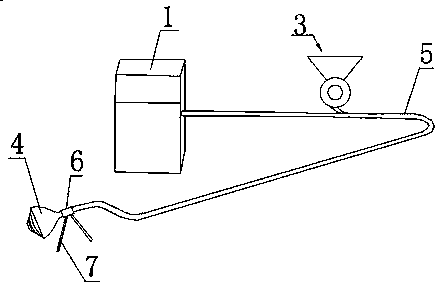

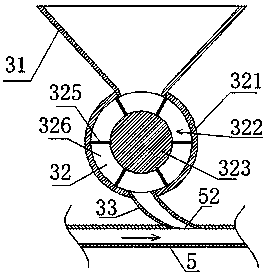

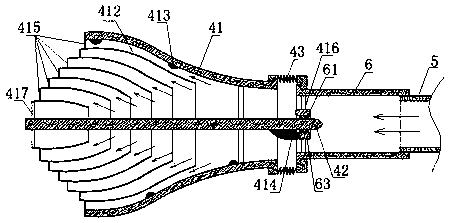

[0023] see Figures 1 to 4 , a pneumatic bait feeding machine, comprising a feeding pipe 5 and a fan 1, a feeder 3 and a sprayer 4 arranged in sequence; the fan 1 communicates with the front end of the feeding pipe 5 to input compressed air into it; the sprayer The feeder 4 communicates with the end of the feed pipe 5 to spray bait outward; the feeder 3 bypasses the feed pipe 5 in the middle of the feed pipe 5 and fills it with bait; the feeder 3 includes The feeding hopper 31, the material distribution chamber 32 and the material introduction pipe 33 arranged in sequence from top to bottom; The swivel 322 with sealing fit; the bottom of the feeding hopper 31 is connected to the inside of the outer cylinder 321 from the upper part of the outer cylinder 321; the upper end of the feeding pipe 33 is connected to the inside of the outer cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com