Method for waste paperboard recycling

A cardboard and waste technology, applied in the field of waste cardboard recycling, can solve the problems of affecting processing, unable to break cardboard, unable to effectively separate waste cardboard iron scraps and other impurities, and achieve the effect of ensuring quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

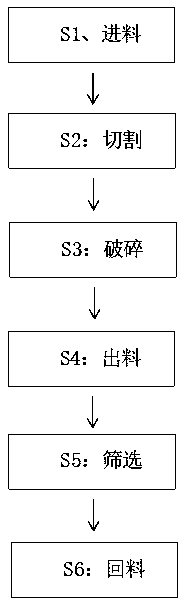

[0055] Such as figure 1 Shown, a kind of method that is used for waste cardboard recycling, this method comprises the following steps:

[0056] S1: Feeding: The discarded cardboard enters the inside of the shell through the feeding port, and under the action of gravity, falls freely and falls between the cutting pieces.

[0057] S2: Cutting: run the cutting motor, the cutting motor drives the first rotating shaft to rotate, the rotation of the first rotating shaft drives the cutting piece to rotate, cut the waste cardboard falling between the cutting pieces in step S1 into strips, and cut into strips The block-shaped waste cardboard provides downward force, and under the action of the force and gravity provided by the cutting sheet, the strip-shaped waste cardboard continues to fall.

[0058] S3: Crushing: Run the crushing motor, the crushing motor drives the second rotating shaft to rotate, the rotation of the second rotating shaft drives the roller to rotate, and the rotati...

Embodiment 2

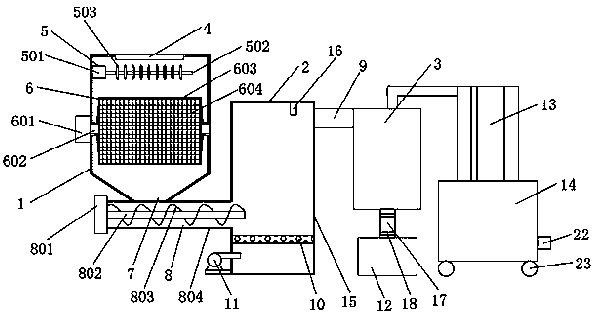

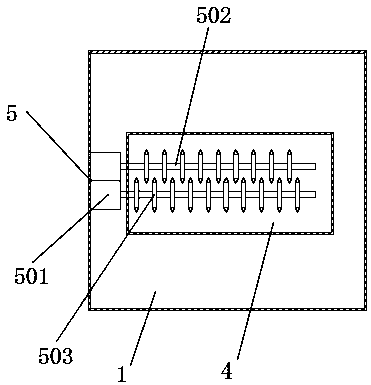

[0077] A waste cardboard recovery device, comprising a housing 1, a cylinder 2 and a cyclone separator 3, the upper part of the housing 1 is provided with a feed port 4, and the inside of the housing 1 adjacent to the feed port 4 is equipped with a cutting Assembly 5, a crushing assembly 6 is installed in the middle of the housing 1, a discharge port 7 is opened at the lower part of the housing 1, and a discharge assembly 8 is installed on the side of the housing 1 adjacent to the discharge port 7 .

[0078] The cylinder body 2 communicates with the discharge end of the discharge assembly 8, a discharge pipe 9 is installed on the upper side of the cylinder body 2, and an air distribution plate 10 is installed inside the cylinder body 2. The lower side of the body 2 is equipped with a fan 11, the outlet end of the fan 11 communicates with the lower side of the cylinder 2, the feed end of the cyclone separator 3 communicates with one side of the discharge pipe 9, and the cyclone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com