High-temperature steam afterheat recycling device based on lead paste smelting

A high-temperature steam and waste heat recovery technology, which is applied in the direction of process efficiency improvement, application, waste heat treatment, etc., can solve environmental heat pollution, waste energy and other problems, and achieve the effects of ensuring effect and quality, reducing emission concentration, and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

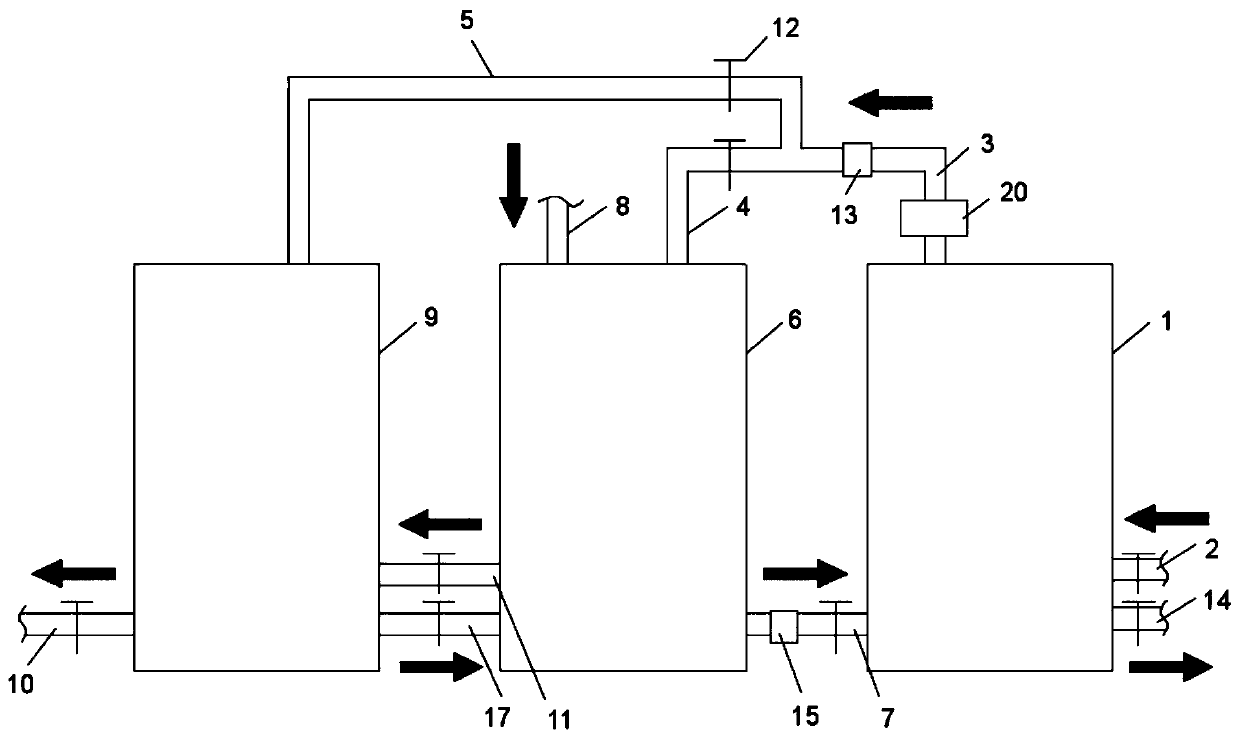

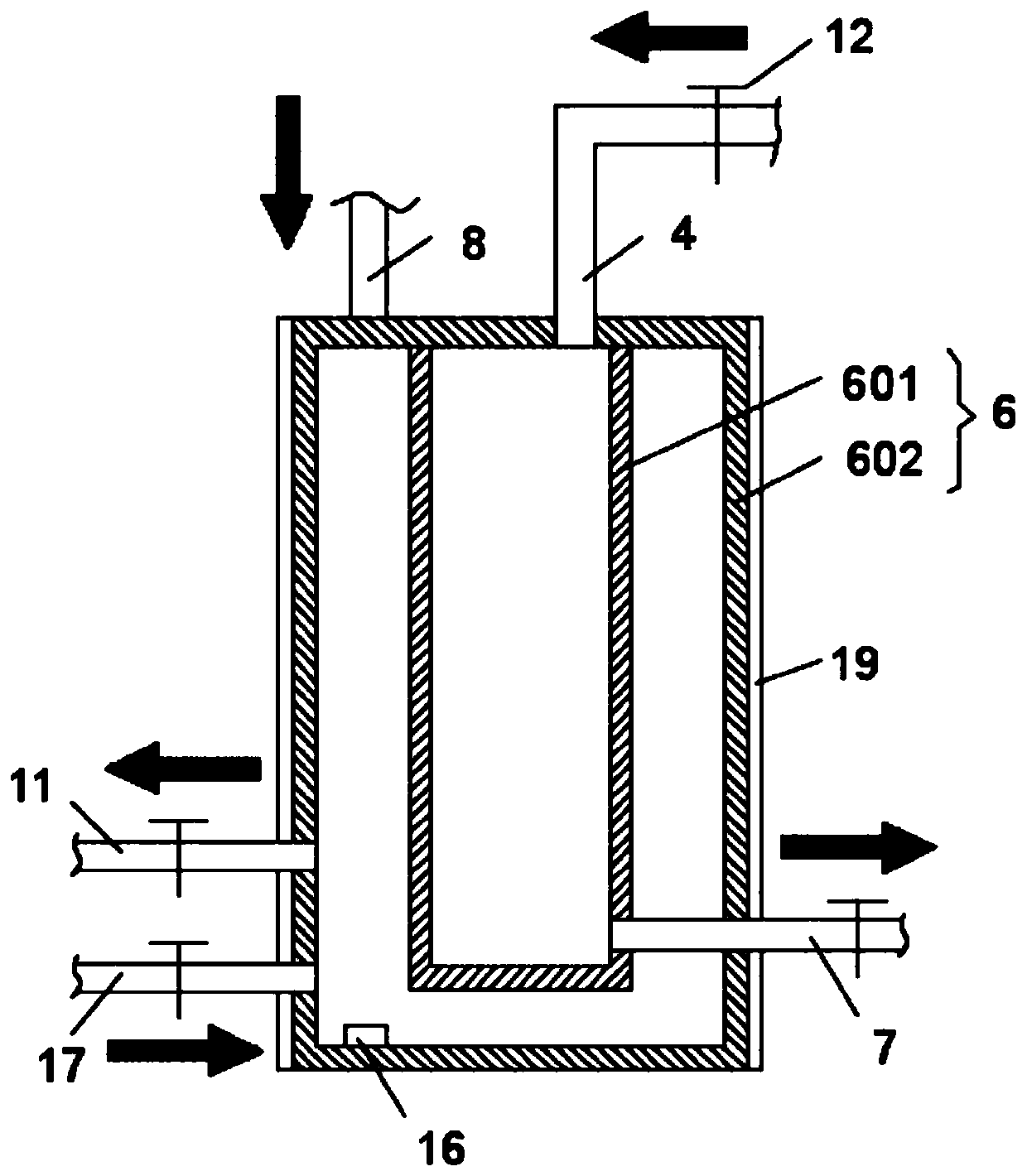

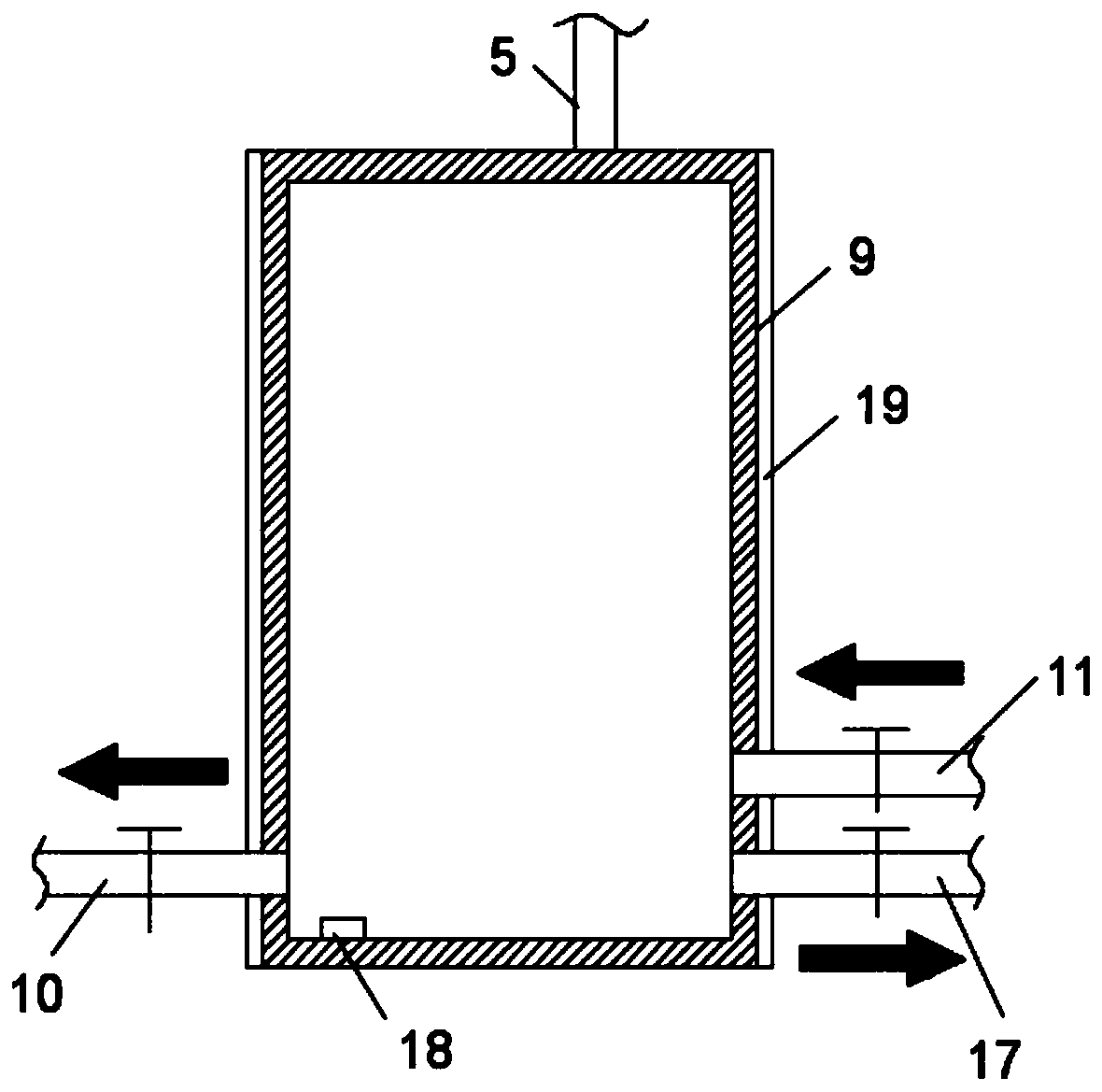

[0020] A blast furnace is required in the process of melting lead paste. The temperature in the blast furnace is relatively high, and a water cooling system is usually installed in it. The temperature of the cooling water in the blast furnace is relatively high, which will cause waste of resources and energy after being directly discharged. The method of this application based on lead paste smelting The high-temperature steam waste heat recovery and utilization device can realize the waste heat recycling of cooling water, such as figure 1 , figure 2 and image 3 As shown, the device includes a cooling water storage tank 1, and the lower right side of the cooling water storage tank 1 is connected with a cooling water inlet pipe 2 and a cooling circulating water pipe 14, and the cooling water inlet pipe 2 is connected with the water cooling equipment of the blast furnace in the lead paste smelting process. connected, the cooling water in the blast furnace water cooling equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com