Soybean leaf ash separation screening machine

A technology for separating and screening soybeans, applied in the field of screening machines, can solve problems affecting health, waste, soybean waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

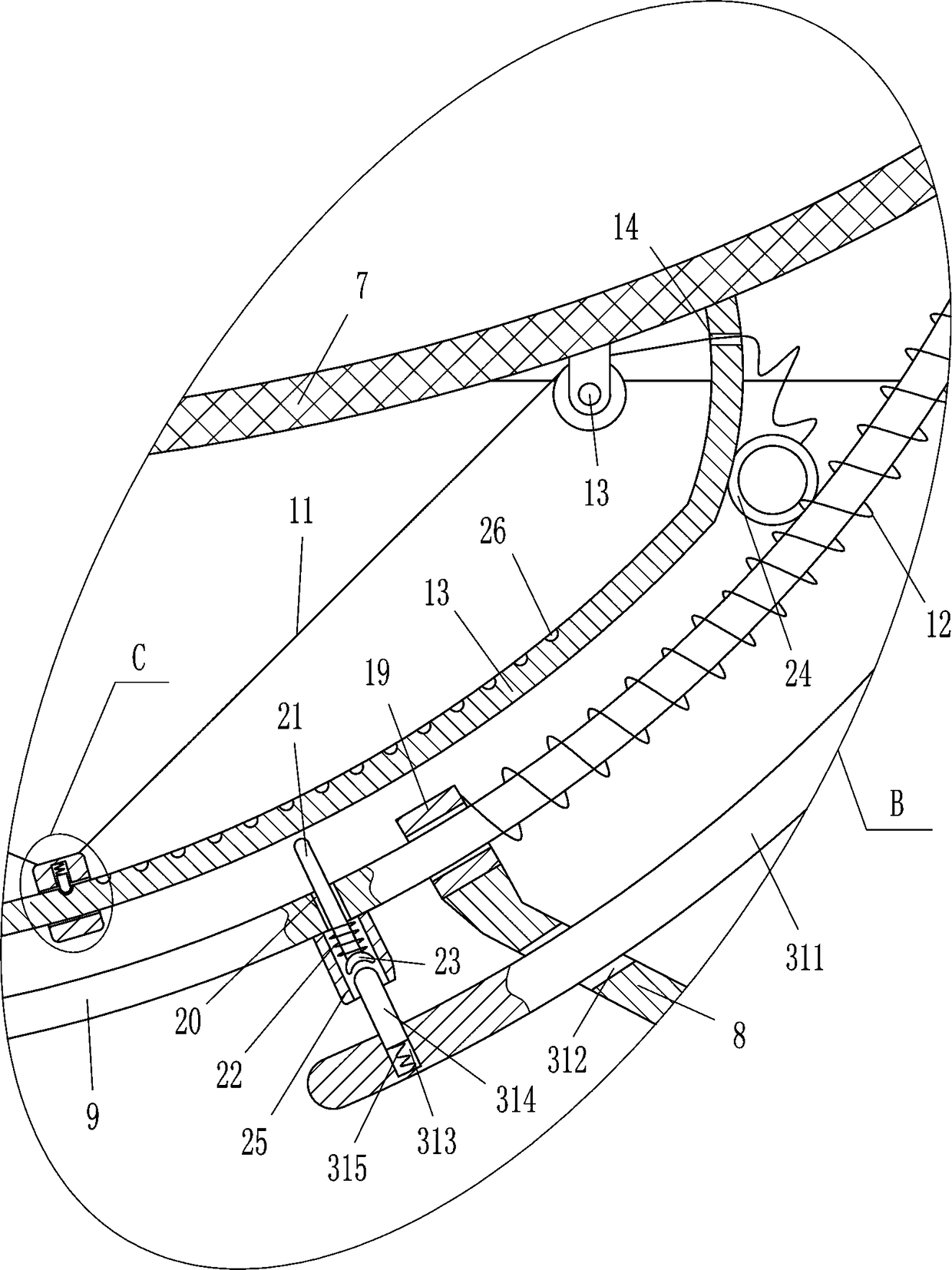

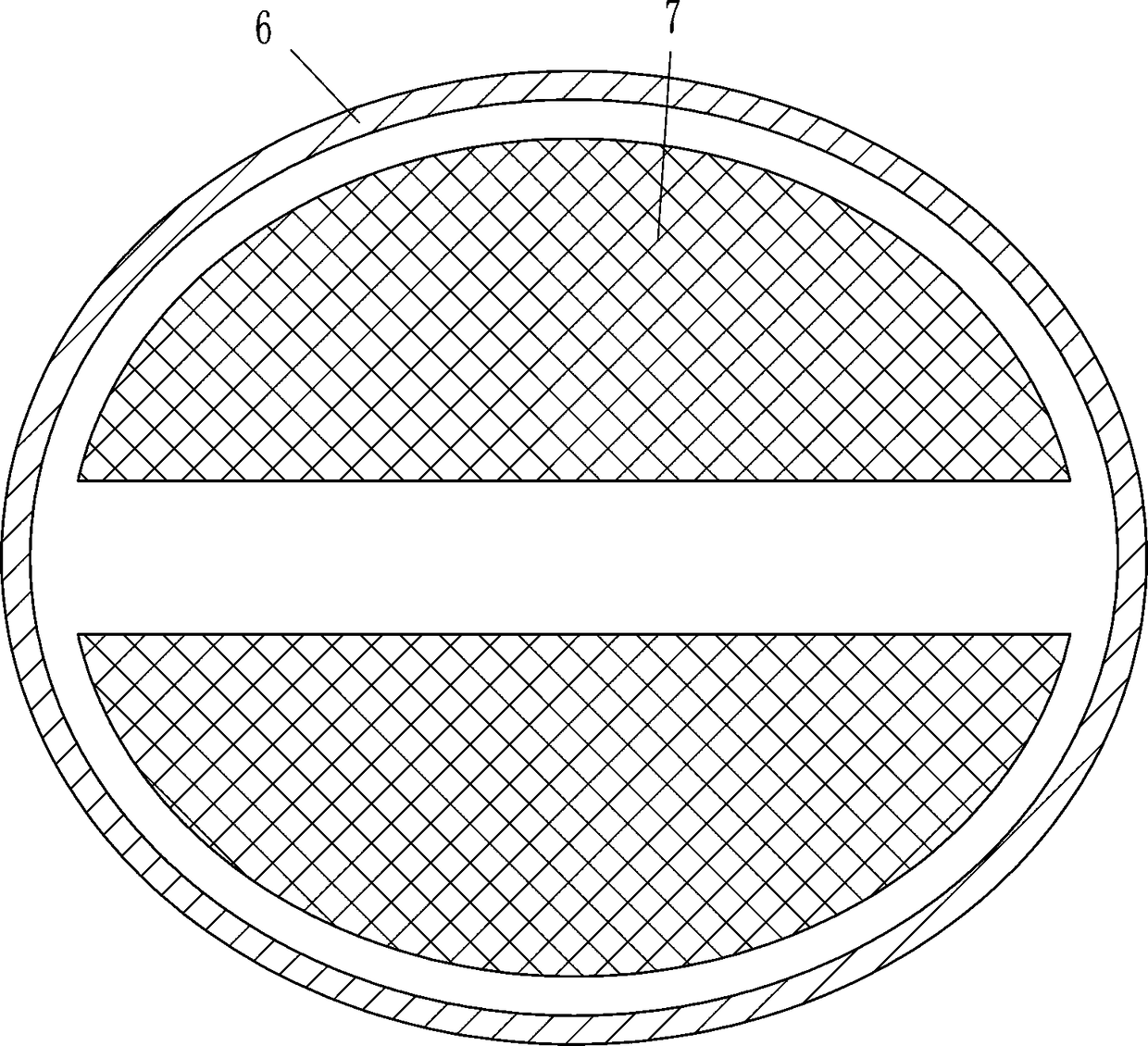

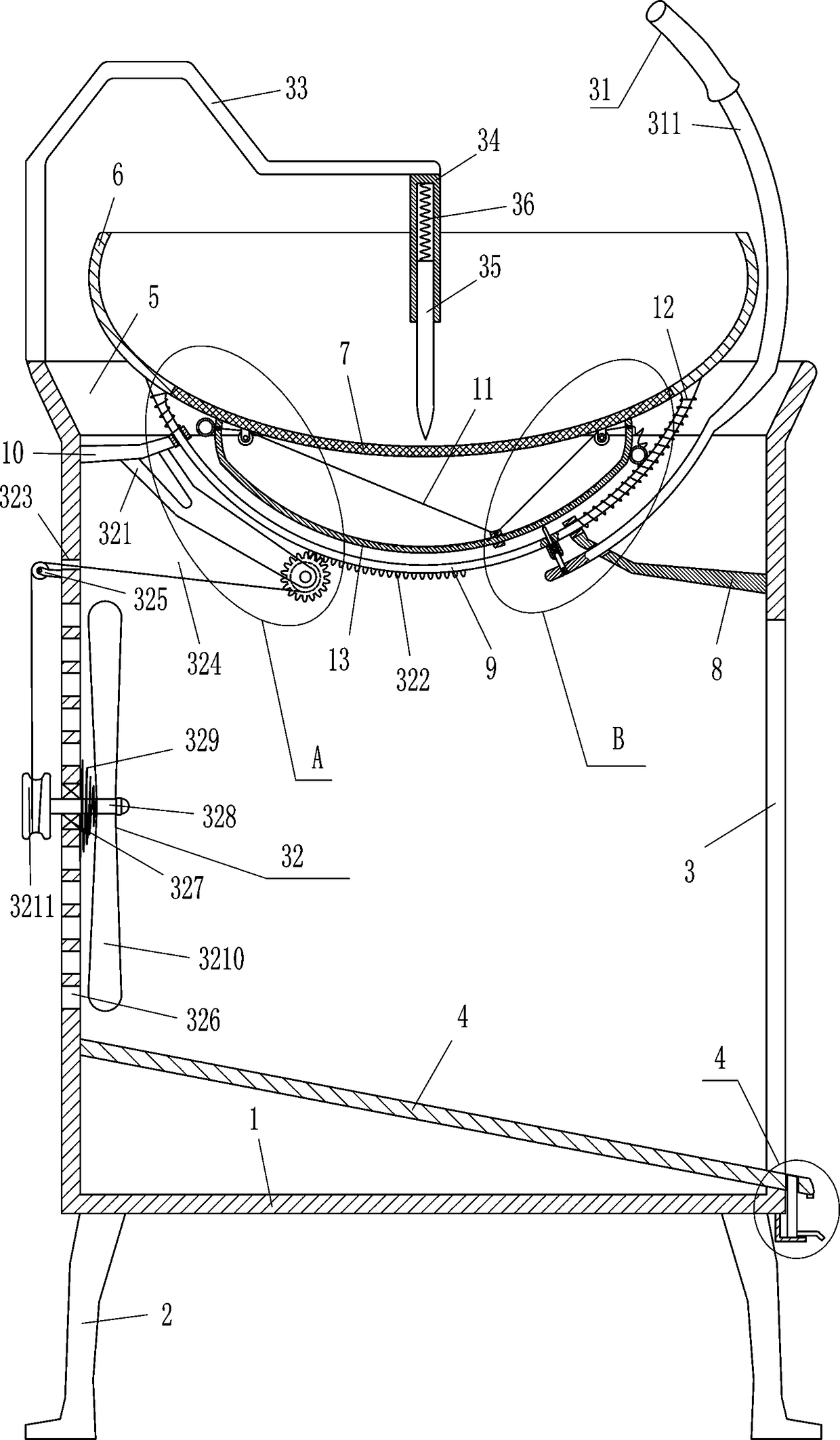

[0019] A soybean leaf ash separation and screening machine, such as Figure 1-5 As shown, it includes a frame body 1, legs 2, slant plate 4, support plate 5, screening frame 6, screen plate 7, first support rod 8, first arc rod 9, second support rod 10, first Backguy 11, first spring 12, second arc rod 13, guide wheel 15, first pull ring 16, second spring 17, first guide sleeve 18, second guide sleeve 19, movable rod 21, third spring 22 , a contact block 23, a second pull ring 24, a sleeve 25, a sliding sleeve 27, a clamping rod 29, a fourth spring 30 and a drive mechanism 31, and the outer bottom of the frame body 1 is fixedly connected with support legs 2 symmetrically on the left and right sides, The frame body 1 is connected with the outrigger 2 by means of bolt connection. There is an opening 3 in the lower part of the right side of the frame body 1. The lower part of the left side of the frame body 1 is fixedly connected with a sloping plate 4. The right end of the slopi...

Embodiment 2

[0021] A soybean leaf ash separation and screening machine, such as Figure 1-5As shown, it includes a frame body 1, legs 2, slant plate 4, support plate 5, screening frame 6, screen plate 7, first support rod 8, first arc rod 9, second support rod 10, first Backguy 11, first spring 12, second arc rod 13, guide wheel 15, first pull ring 16, second spring 17, first guide sleeve 18, second guide sleeve 19, movable rod 21, third spring 22 , a contact block 23, a second pull ring 24, a sleeve 25, a sliding sleeve 27, a clamping rod 29, a fourth spring 30 and a drive mechanism 31, and the outer bottom of the frame body 1 is fixedly connected with support legs 2 symmetrically on the left and right sides, There is an opening 3 in the lower part of the right side of the frame body 1, and a sloping plate 4 is fixedly connected to the lower part of the left side of the frame body 1. The right end of the sloping plate 4 passes through the opening 3 and is located outside the frame body 1...

Embodiment 3

[0024] A soybean leaf ash separation and screening machine, such as Figure 1-5 As shown, it includes a frame body 1, legs 2, slant plate 4, support plate 5, screening frame 6, screen plate 7, first support rod 8, first arc rod 9, second support rod 10, first Backguy 11, first spring 12, second arc rod 13, guide wheel 15, first pull ring 16, second spring 17, first guide sleeve 18, second guide sleeve 19, movable rod 21, third spring 22 , a contact block 23, a second pull ring 24, a sleeve 25, a sliding sleeve 27, a clamping rod 29, a fourth spring 30 and a drive mechanism 31, and the outer bottom of the frame body 1 is fixedly connected with support legs 2 symmetrically on the left and right sides, There is an opening 3 in the lower part of the right side of the frame body 1, and a sloping plate 4 is fixedly connected to the lower part of the left side of the frame body 1. The right end of the sloping plate 4 passes through the opening 3 and is located outside the frame body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com