Separation process for metal stamping part

A technology for separating processes and stamping parts, applied in the field of metal stamping, can solve problems such as easy adhesion of debris, unqualified, blanking parts defects, etc., to achieve the effect of ensuring smoothness, good effect, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

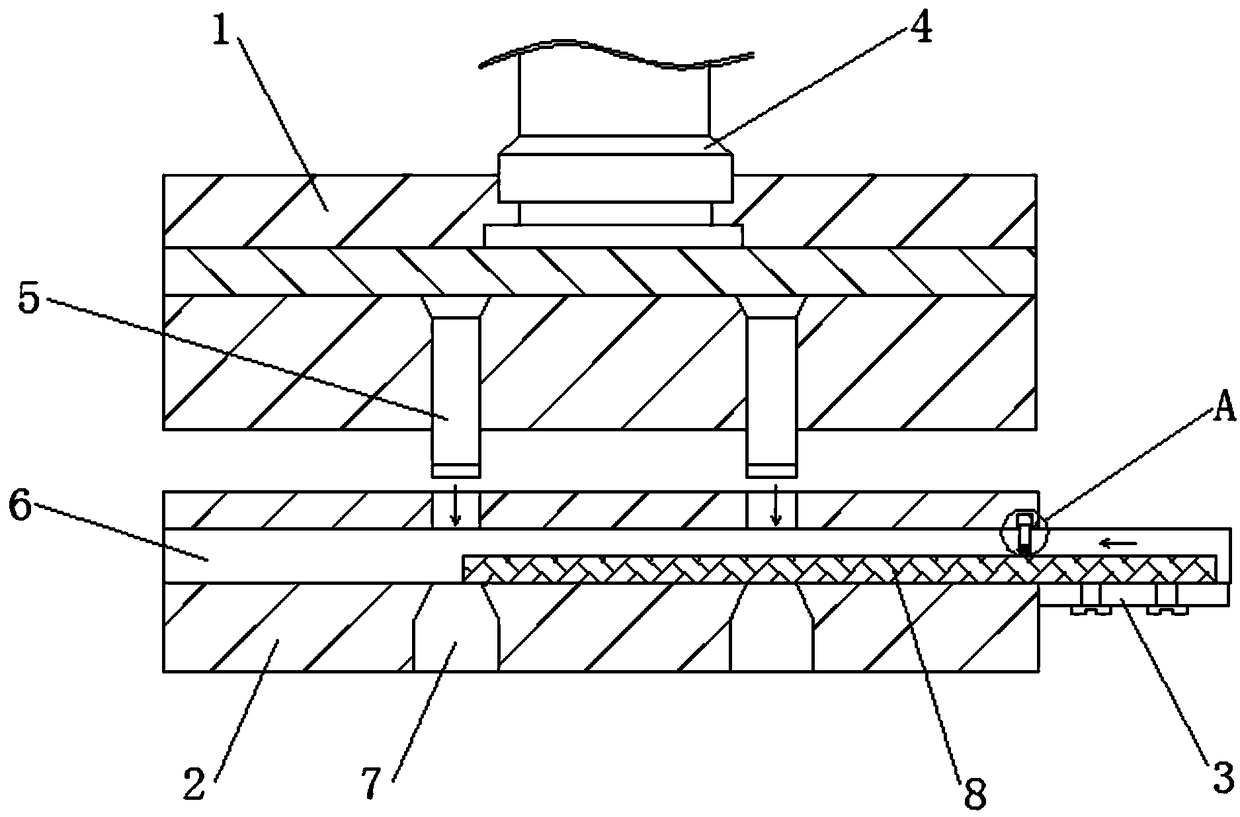

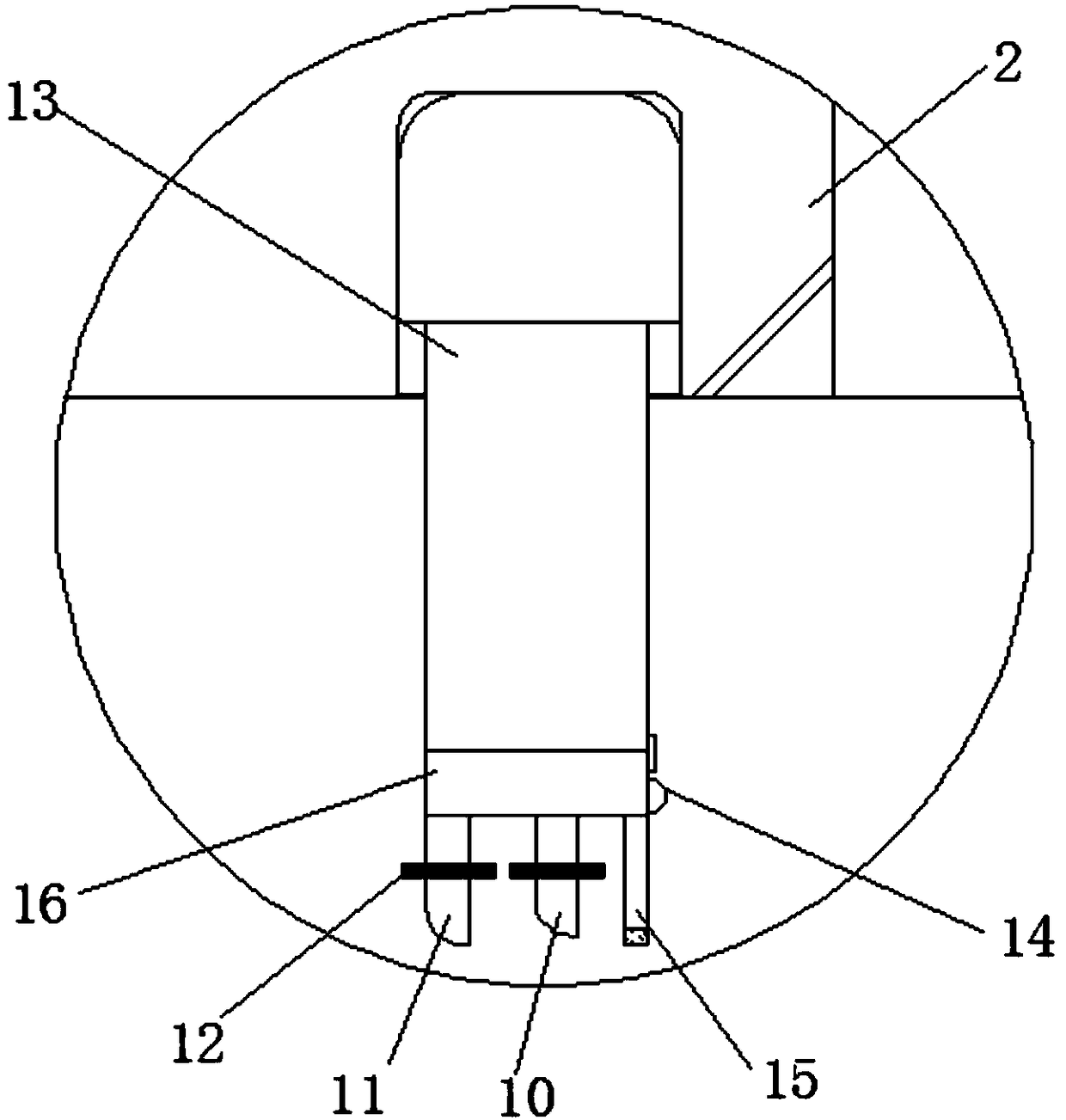

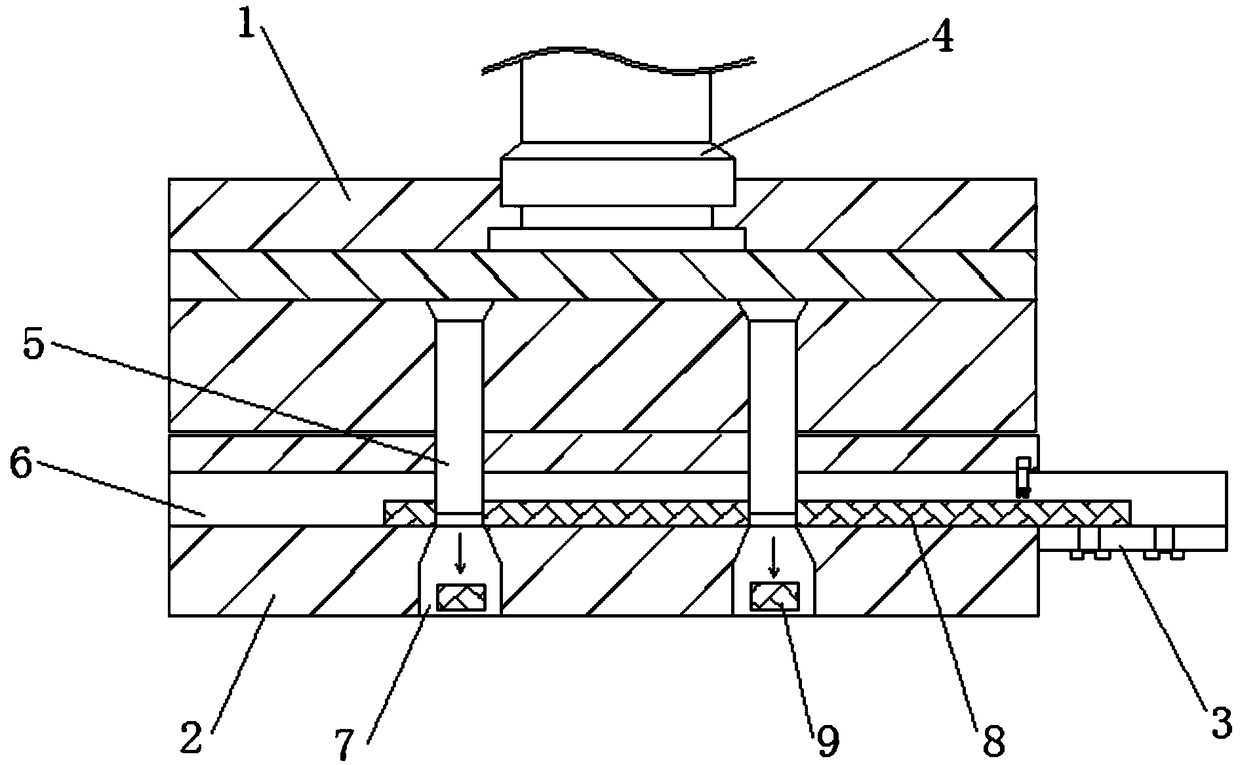

[0051] see Figure 1-5 , a separation process of metal stamping parts, including sheet metal parts 8 and a separation device, the separation device is connected with a monitoring mechanism 14 and a scraping mechanism, and its separation process is:

[0052] The first step, feeding: put the formed sheet metal part 8 on the feeding control mechanism 3 at the feeding end;

[0053] The second step, push material: After confirming that the discharge is completed correctly, the feed control mechanism 3 pushes the sheet metal part 8 into the feed channel 6;

[0054] The third step, detection: use the monitoring mechanism 14 to detect the surface of the sheet metal part 8, the laser flatness measuring instrument detects the flatness of the surface of the sheet metal part 8, and the high-definition camera can take pictures and monitor the sheet metal part 8 to be blanked in real time , when the laser flatness measuring instrument detects that the flatness of the sheet metal part 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com