Continuous automobile tire printing and drying equipment

A technology for automobile tires and drying equipment, which is applied to printing devices, printing, typewriters, etc., can solve the problems of inability to dry the ink on the tire surface in time, and the use effect is not ideal, and achieves long drying time and large drying range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

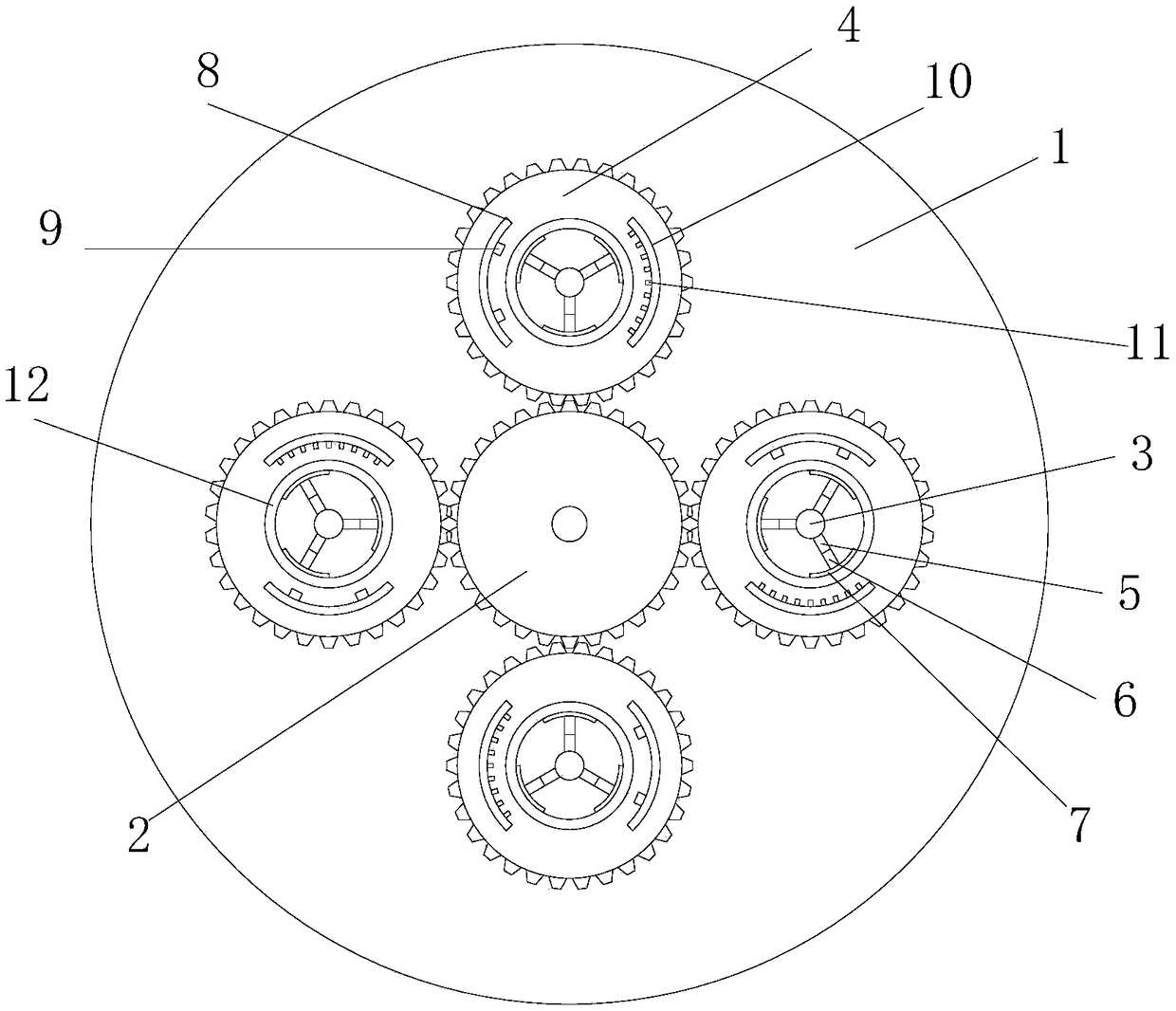

[0013] refer to figure 1 , the present invention proposes a continuous type automobile tire printing and drying equipment, including a workbench 1, a driving gear 2, a first driving mechanism, a plurality of support shafts 3, a plurality of installation turntables 4 and a plurality of tire printing and drying mechanisms; Gear 2 is rotatably installed on workbench 1, and the first drive mechanism is connected with drive gear 2 to drive drive gear 2 to rotate. A plurality of support shafts 3 are fixedly installed on workbench 1 and are distributed around drive gear 2 as the center. A plurality of installation turntables 4 are respectively rotated and installed on the bottom ends of a plurality of support shafts 3, and the outer circumferences of the plurality of installation turntables 4 are evenly distributed with sawtooth meshing with the driving gear 2; One corresponding setting, the tire printing mechanism includes a tire support frame, a printing component and a drying comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com