high pressure container

A technology of anti-high pressure and container, which is applied in the field of container equipment, can solve the problems of limited anti-pressure coefficient, increase container production cost and market price, etc., and achieve the effect of improving external pressure resistance, fast assembly process, and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

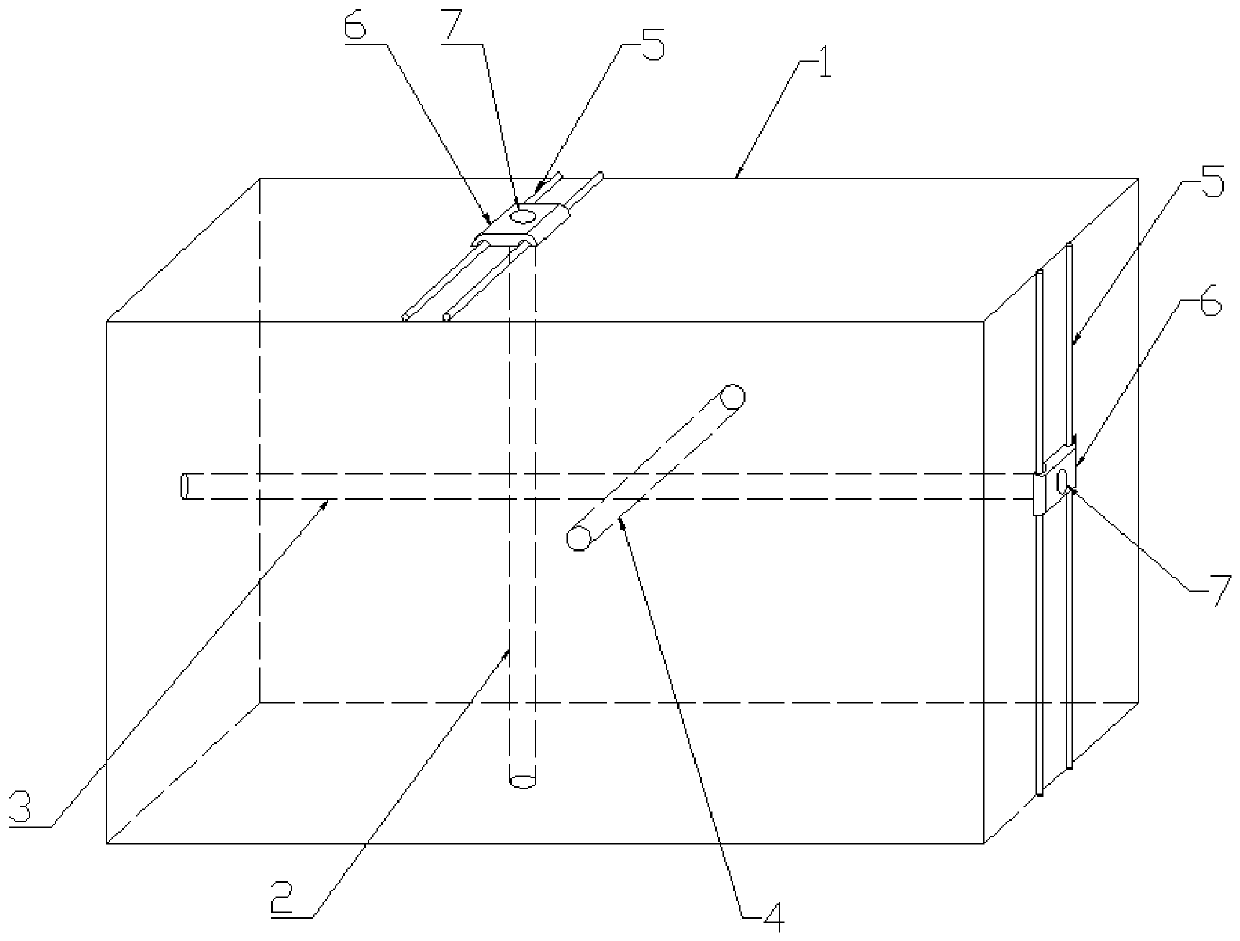

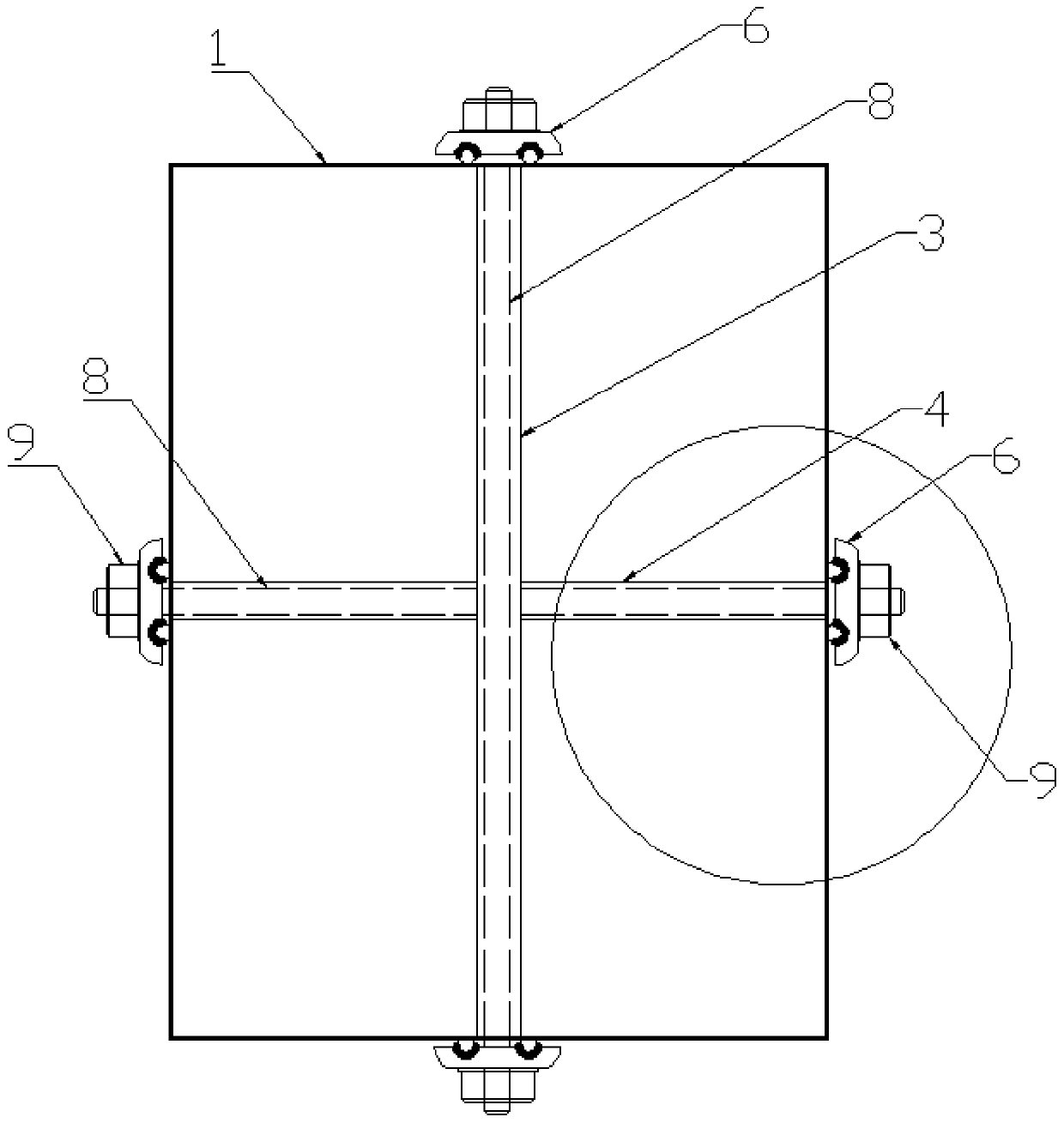

[0033] like Figure 1-Figure 3 As shown, a kind of anti-high pressure container is provided in the present embodiment, comprises a container body 1, and described container body 1 is set as the tank body of cubic structure (cube structure is only the preferred technical scheme of this embodiment, also can be Other shapes and structures, such as trapezoidal body, hexagonal body, etc.), the tank body includes three side wall groups, and the three side wall groups are respectively A side wall group, B side wall group and C side wall group.

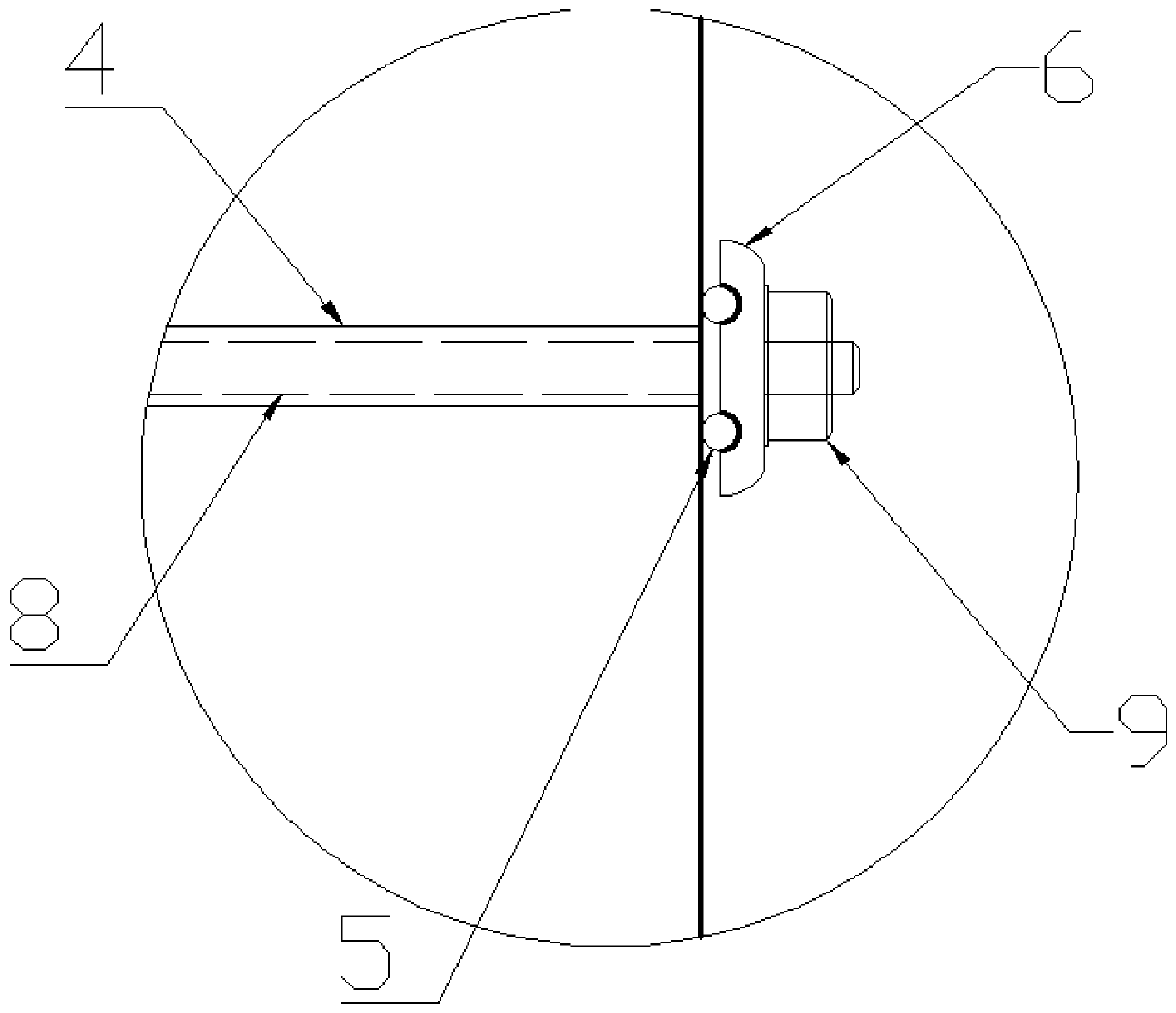

[0034] A side wall group, B side wall group and C side wall group are all composed of opposite and parallel side walls, a casing runs through the two side walls and the outer wall of the casing is sealed with the two side walls; the A side The sleeves corresponding to the wall group, B side wall group and C side wall group are A sleeve 3, B sleeve 4 and C sleeve 2 respectively. Preferably, the two ends of the A sleeve 3, the B sleeve 4 and t...

Embodiment 2

[0041] like figure 1 , Figure 4 As shown, a kind of anti-high pressure container is provided in the present embodiment, comprises a container body 1, and described container body 1 is set as the tank body of cubic structure (cube structure is only the preferred technical scheme of this embodiment, also can be Other shapes and structures, such as trapezoidal body, hexagonal body, etc.), the tank body includes three side wall groups, and the three side wall groups are respectively A side wall group, B side wall group and C side wall group.

[0042] A side wall group, B side wall group and C side wall group are all composed of opposite and parallel side walls, a casing runs through the two side walls and the outer wall of the casing is sealed with the two side walls; the A side The sleeves corresponding to the wall group, B side wall group and C side wall group are A sleeve 3, B sleeve 4 and C sleeve 2 respectively. Preferably, the two ends of the A sleeve 3, the B sleeve 4 an...

Embodiment 3

[0049] like Figure 5 As shown, a high-pressure container is provided in this embodiment, including three container bodies (the use of three container bodies is only the preferred solution of this embodiment, and more container bodies can also be used), and the container body is designed It is a tank body with a cubic structure (the cubic structure is only the preferred technical solution of this embodiment, and it can also be other shapes and structures, such as: trapezoidal body, hexagonal body, etc.), and the tank body includes three said side wall groups, The three sidewall groups are A sidewall group, B sidewall group and C sidewall group.

[0050] The above-mentioned A side wall group, B side wall group and C side wall group are all composed of opposite and parallel side walls, a casing runs through the two side walls and the outer wall of the casing is sealed with the two side walls; A The sleeves corresponding to the side wall group, B side wall group and C side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com