A membraneless solid-liquid and gas-liquid separator and system

A gas-liquid separator, solid-liquid separation technology, applied in separation methods, precipitation separation, chemical instruments and methods, etc., can solve the problems of low sludge production rate of excess sludge, high equipment maintenance costs, large equipment investment, etc. The effect of good sewage treatment, elimination of secondary pollution sources, and simple equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

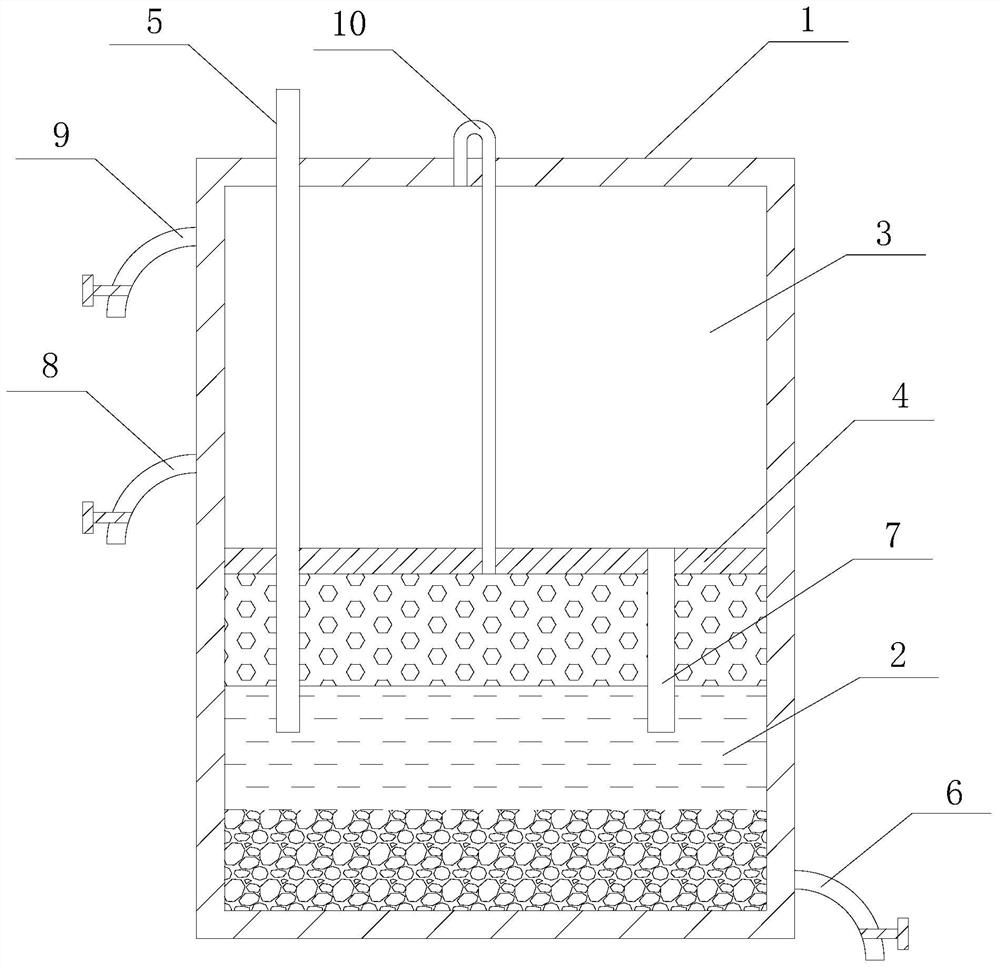

[0036] Such as figure 1 , figure 2 with image 3 As shown, the present embodiment provides a membraneless solid-liquid and gas-liquid separator, including a closed container 1, the closed container 1 can be round, square or special-shaped, and the closed container 1 can use steel plates, reinforced concrete, Made of brick-concrete or plastic, the size of the closed container 1 can be designed according to actual needs to meet the needs of various fields. The closed container 1 is provided with a solid-liquid separation chamber 2, and above the solid-liquid separation chamber 2 is provided with a gas-liquid separation chamber 3, and the solid-liquid separation chamber 2 and the gas-liquid separation chamber 3 are connected to each other through a diaphragm body 4. isolation. The diaphragm body 4 divides the inside of the closed container 1 into two parts, the upper part is the gas-liquid separation chamber 3 , and the lower part is the solid-liquid separation chamber 2 . S...

Embodiment 2

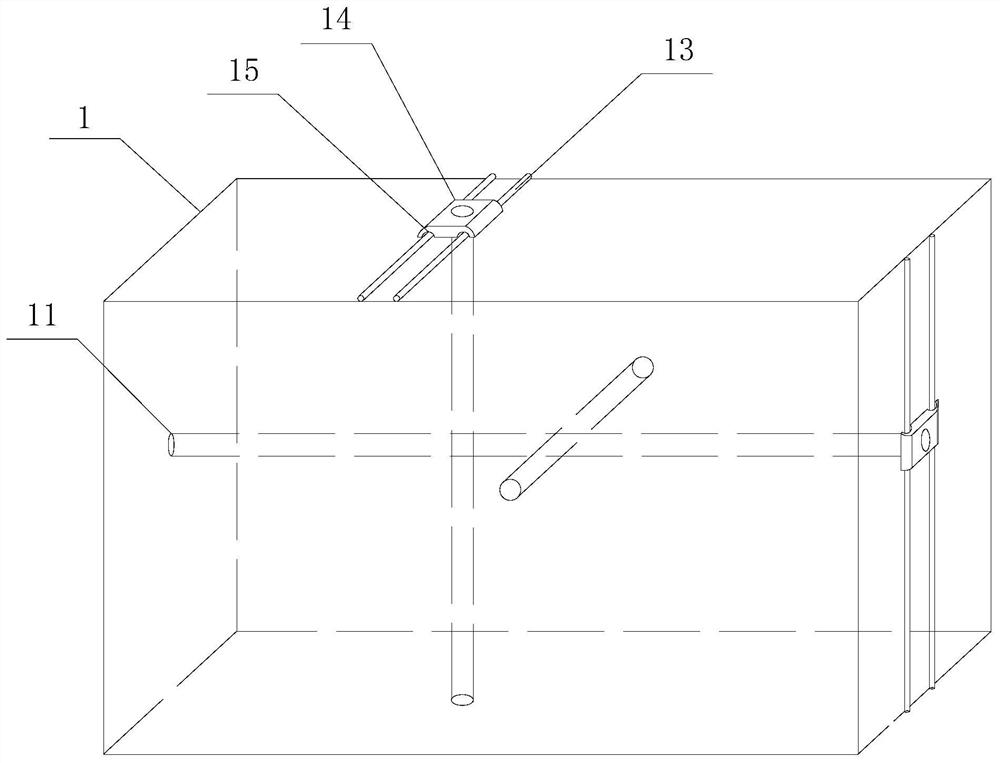

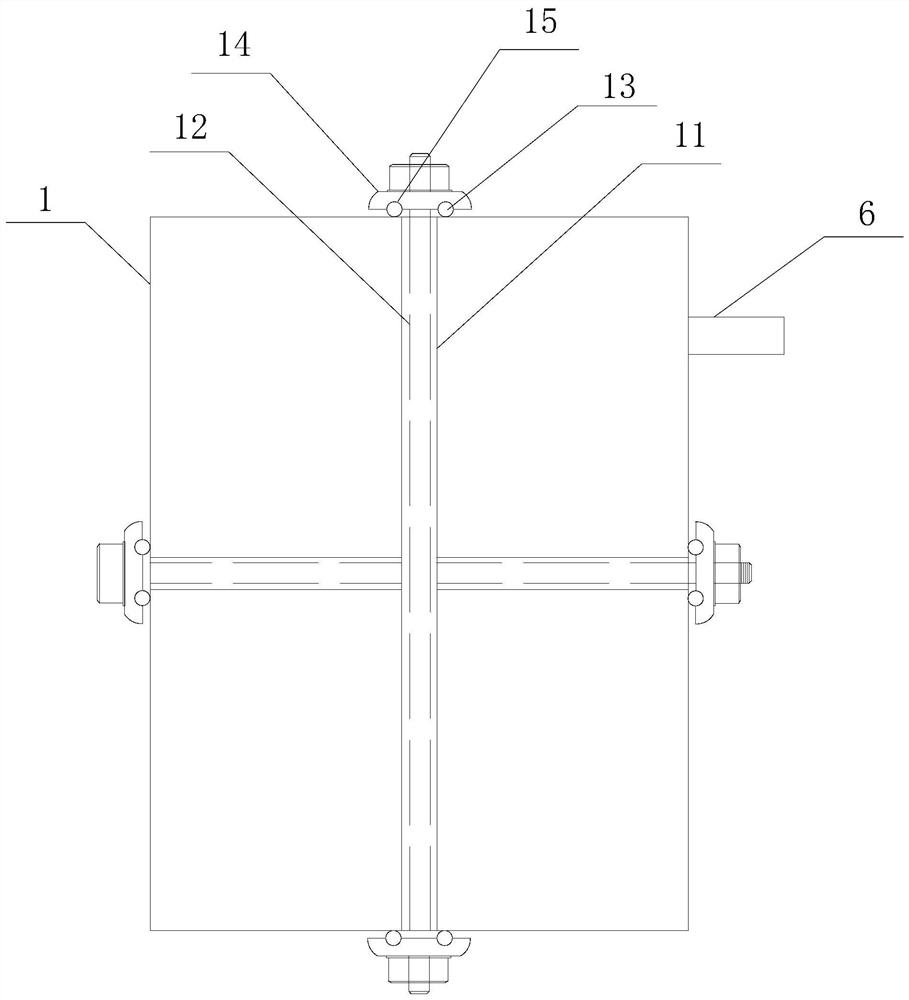

[0049] Such as Figure 4 with Figure 5 As shown, the present embodiment provides a membraneless solid-liquid and gas-liquid separator, including a closed container 1, the closed container 1 can be round, square or special-shaped, and the closed container 1 can use steel plates, reinforced concrete, Made of brick-concrete or plastic, the size of the closed container 1 can be designed according to actual needs to meet the needs of various fields. The closed container 1 is provided with a plurality of solid-liquid separation chambers 2 connected in sequence, and the plurality of solid-liquid separation chambers 2 are arranged side by side. A gas-liquid separation chamber 3 is arranged above each solid-liquid separation chamber 2 , and each gas-liquid separation chamber 3 communicates in sequence.

[0050] Wherein, a plurality of solid-liquid separation chambers 2 include the solid-liquid separation chamber 2 at the head, the solid-liquid separation chamber 2 at the middle and ...

Embodiment 3

[0071] Such as Figure 8 As shown, this embodiment provides a membraneless solid-liquid and gas-liquid separation system. The membraneless solid-liquid and gas-liquid separation system is formed by stacking multiple membraneless solid-liquid and gas-liquid separators. Surround or combine with the gas-liquid separator. The membraneless solid-liquid and gas-liquid separator includes a closed container 1. The closed container 1 can be rectangular, trapezoidal, round or shaped, preferably square. There are multiple sequentially connected solid-liquid separation chambers in the closed container 1. 2. Multiple solid-liquid separation chambers 2 are arranged side by side. A gas-liquid separation chamber 3 is arranged above each solid-liquid separation chamber 2 , and each gas-liquid separation chamber 3 communicates in sequence. Wherein, the plurality of solid-liquid separation chambers 2 include a solid-liquid separation chamber 2 at the head, a solid-liquid separation chamber 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com