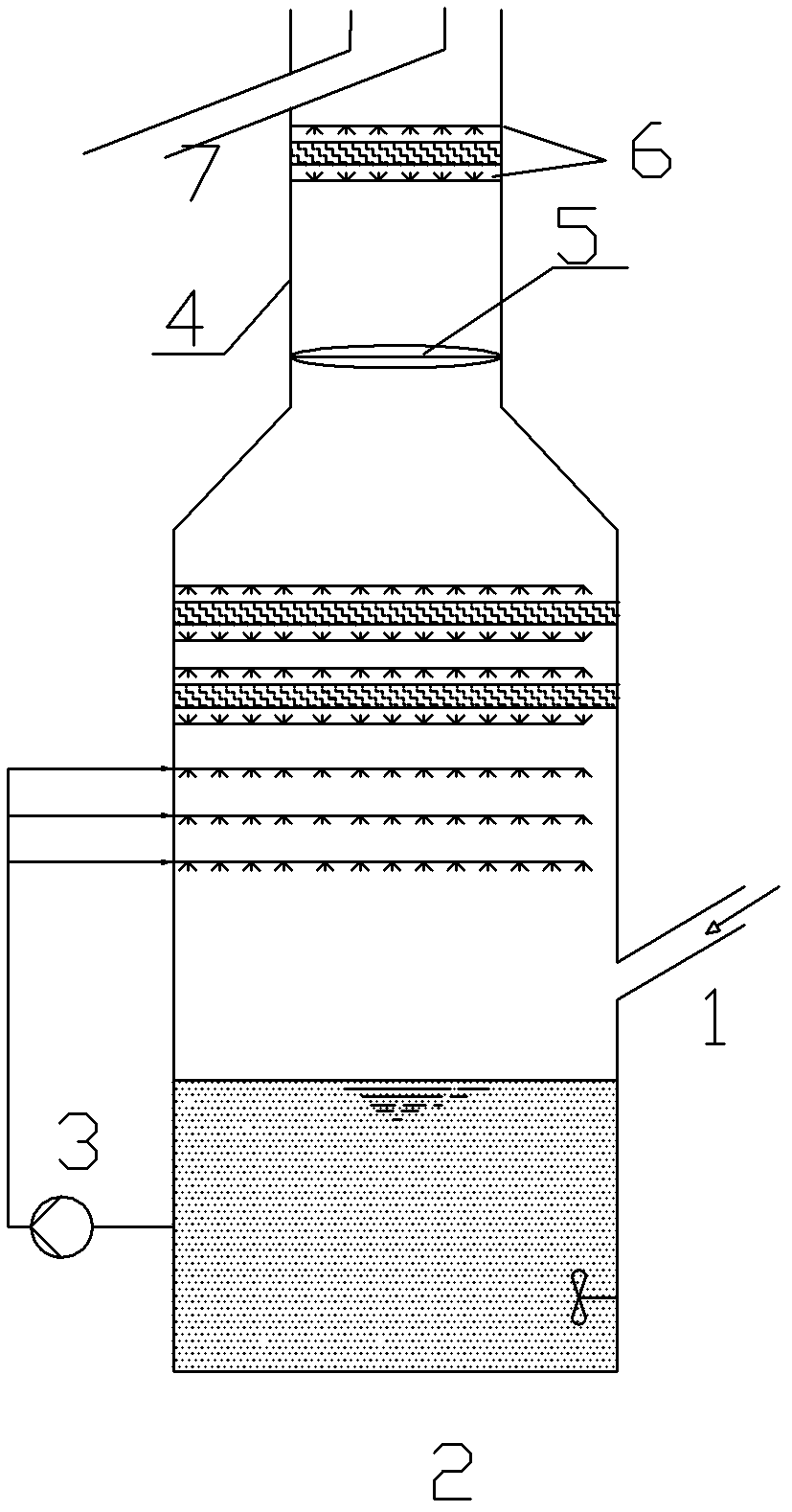

Wet desulphurization process and device for sintering machine flue gas

A technology of wet desulfurization and sintering machine, applied in the direction of combination device, separation method, air quality improvement, etc., can solve the problems of large environmental pollution, increase the resistance of flue gas of desulfurization system, and form smoke and rain, and save investment and operation cost, Improve the effect of governance and increase the effect of lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A steel group 1×160m 2 Sintering machine flue gas and blast furnace gas account for 37% of the total flue gas volume. With the device and process of the present invention, the desulfurizer is limestone. The liquid-gas ratio of wet desulfurization is 8L / m 3 , the pH is controlled at 5.3, the gas velocity in the direct chimney is 17.8m / s, the pressure at the top of the absorption tower is controlled at -100-50Pa, and the inlet flue gas SO 2 The concentration is 2780mg / m 3 , CO concentration is 11300ppm. The desulfurization efficiency is 96.3%, the flue gas temperature at the outlet of the straight chimney is 87°C, and the dust content at the outlet is 28mg / m 3 , the outlet CO concentration is 172ppm, and there is no smoke and rain at the outlet.

Embodiment 2

[0035] A steel group 2×240m 2 Sintering machine flue gas and blast furnace gas account for 33% of the total flue gas volume. With the device and process of the present invention, the desulfurizer is lime. The liquid-gas ratio of wet desulfurization is 10L / m 3 , the pH is controlled at 5.2, the gas velocity in the direct chimney is 15.6m / s, the pressure at the top of the absorption tower is controlled at -120-80Pa, and the inlet flue gas SO 2 The concentration is 2220mg / m 3 , CO concentration is 9800ppm. The desulfurization efficiency is 97.9%, the flue gas temperature at the outlet of the straight chimney is 85°C, and the dust content at the outlet is 31mg / m 3 , the CO concentration at the outlet is 145ppm, and there is no smoke and rain at the outlet.

Embodiment 3

[0037] A steel group 1×180m 2 Sintering machine flue gas and blast furnace gas account for 35% of the total flue gas volume. With the device and process of the present invention, the desulfurizer is limestone. The liquid-gas ratio of wet desulfurization is 7L / m 3 , the pH is controlled at 5.4, the gas velocity in the direct chimney is 16.9m / s, the pressure at the top of the absorption tower is controlled at -110-70Pa, and the inlet SO 2 The concentration is 3260mg / m 3 , CO concentration is 10300ppm. The desulfurization efficiency is 96.1%, the flue gas temperature at the outlet of the straight chimney is 88°C, and the dust content at the outlet is 26mg / m 3 , the outlet CO concentration is 121ppm, and there is no smoke and rain at the outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com