Glass plate for manufacturing of protein gel

A protein gel and glass plate technology is applied in the field of making glass plates for protein gels, which can solve the problems of easy generation of bubbles and gel breakage, and achieve the effect of accurate sample addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

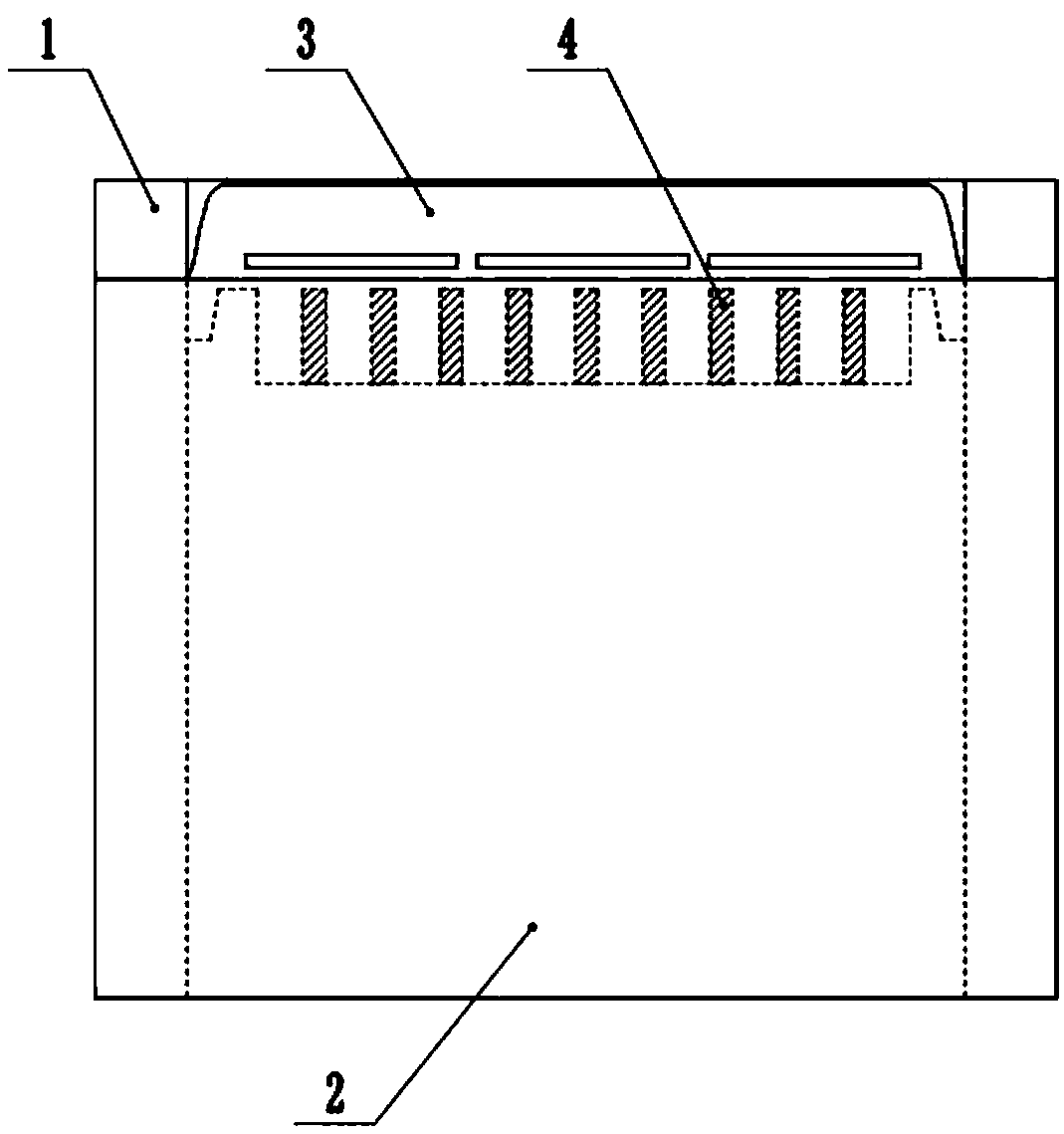

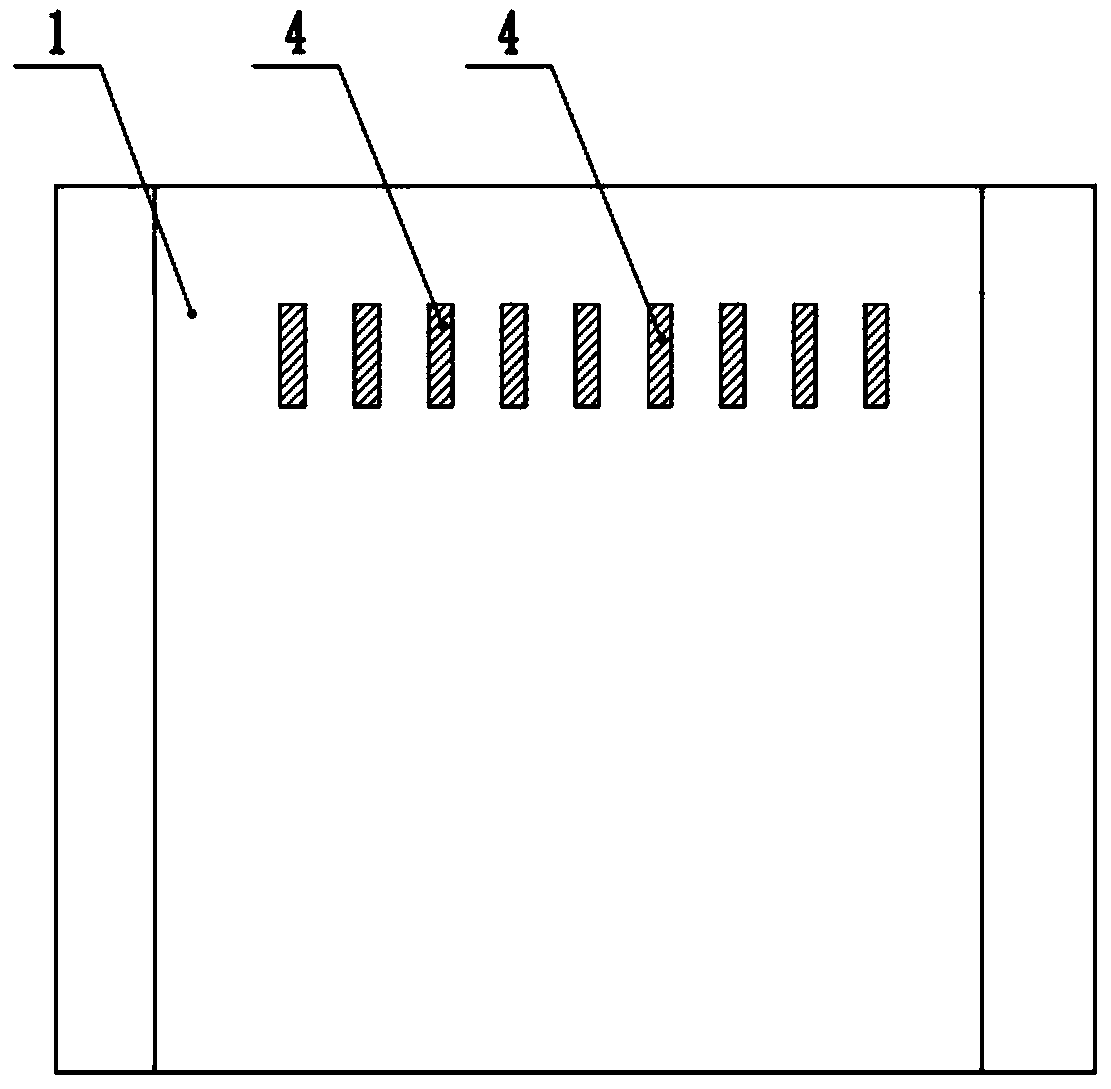

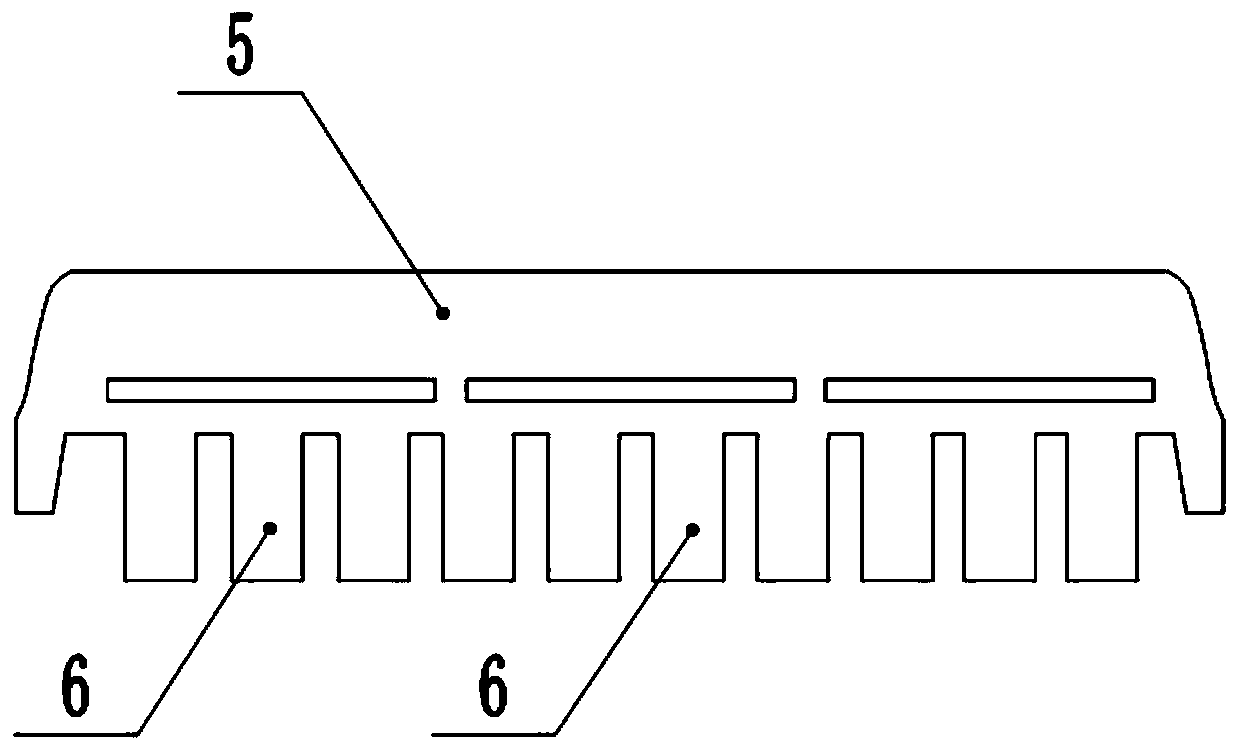

[0015] refer to Figure 1 to Figure 4 , according to the present invention, a glass plate for making protein gel, comprising: a large glass plate 1, a small glass plate 2 and a comb 3, the comb 3 is composed of a comb back 5 and comb teeth 6, and the comb 3 is suitable for inserting when gelling Between the large glass plate 1 and the small glass plate 2, several wedge-shaped glass strips 4 are arranged at intervals along the insertion direction of the comb 3 on the top of the large glass plate 1, and the wedge-shaped glass strips 4 are suitable for extending into the comb when the comb 3 is inserted. In each gap between the comb teeth 6 of 3.

[0016] During the process of preparing the protein gel, inserting the comb 3 will often cause the gel to overflow, which will affect the quality of the protein gel; pulling out the comb 3 will cause the strip of the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com