Bridge plug capable of washing sand

A technology for sand washing and bridge plugs, applied in the field of oilfield exploitation, can solve the problems of tools not being able to be put in place, construction risks in construction operations, and inability to apply sand production, so as to reduce operation risks, improve construction cost rates, and shorten construction periods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

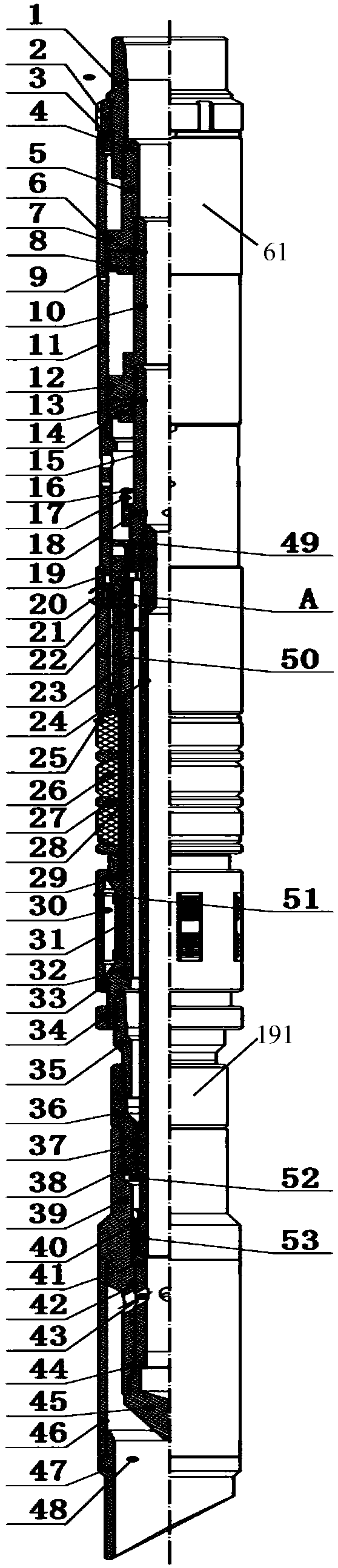

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

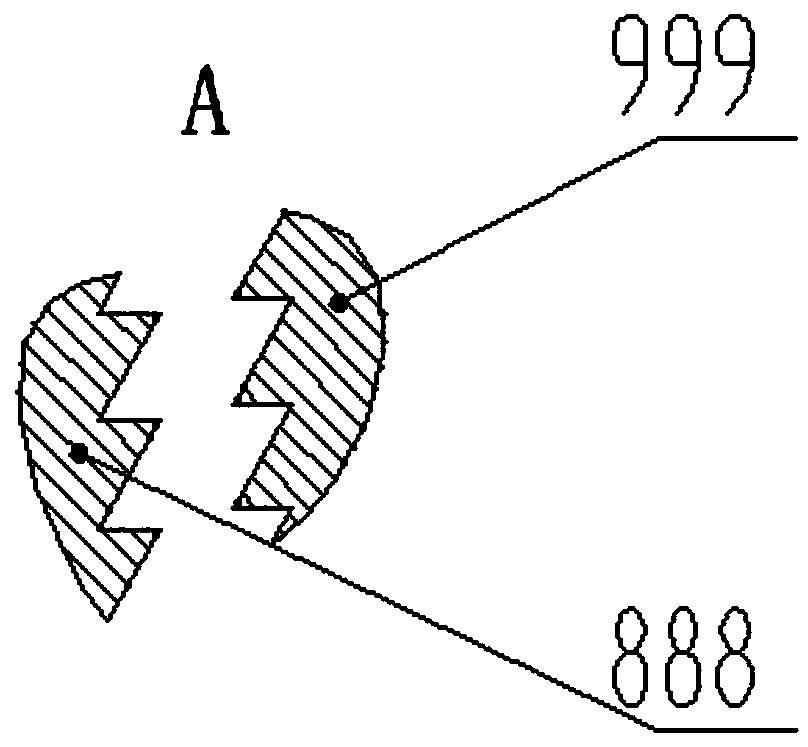

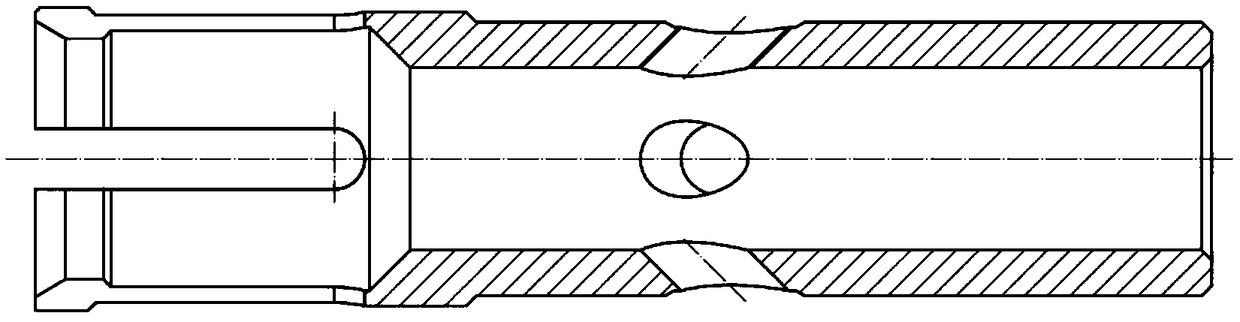

[0030] The invention provides a kind of flushable sand bridge plug, see Figure 1-3 , including an upper joint 1, an upper central pipe 5, an intermediate central pipe 10, and a lower central pipe 15 which are threaded sequentially from top to bottom; the outer thread of the lower end of the lower central pipe 15 is connected with a shear ring 22, and the outer thread of the lower end of the shear ring 22 Connected with a central tube 23; the inner side of the lower end of the lower central tube 15 is threaded with a ball seat 19, the lower end of the ball seat 19 is threaded with an intubation tube 24, and the lower end of the intubation tube 24 is provided with a self-locking head 53;

[0031] The lower end of the center pipe 23 is threaded with a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com