Oil pressure self-adaptive method and device based on PI control

An adaptive, hydraulic technology, applied in mechanical equipment, clutches, etc., can solve the problems of increasing software coverage, large differences in oil pressure, and poor hardware consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

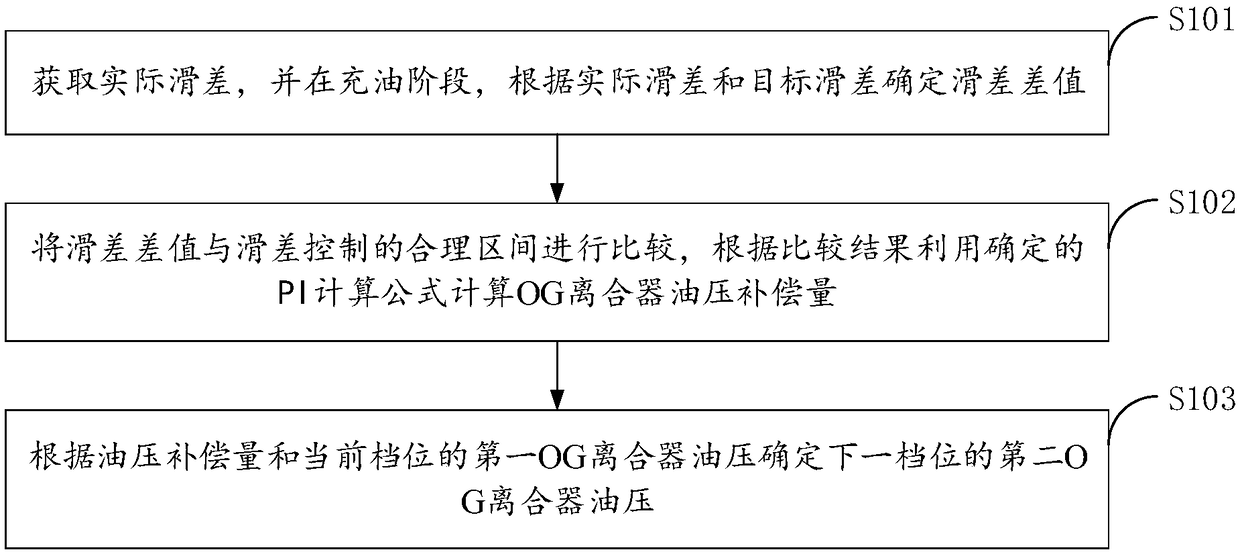

[0055] figure 1 It is a flow chart of an oil pressure adaptive method based on PI control provided by Embodiment 1 of the present invention.

[0056] refer to figure 1 , an embodiment of the present invention provides a PI control-based oil pressure adaptive method, which may include:

[0057] Step S101, obtaining the actual slip, and determining the slip difference according to the actual slip and the target slip during the oil filling stage;

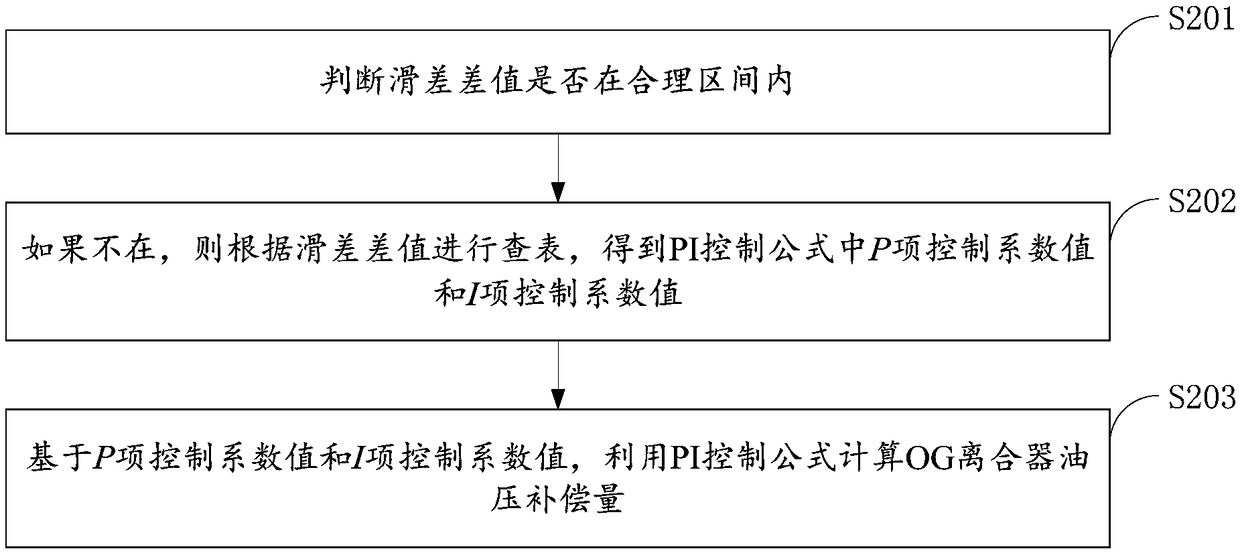

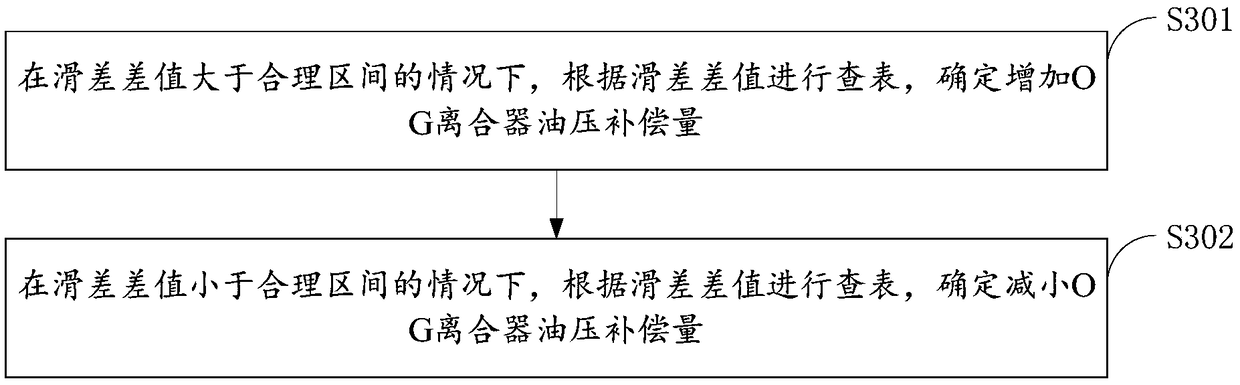

[0058] Step S102, comparing the slip difference with the reasonable range of slip control, and calculating the OG clutch oil pressure compensation amount using the PI control formula according to the comparison result;

[0059] Step S103, determining the second OG clutch oil pressure of the next gear according to the oil pressure compensation amount and the first OG clutch oil pressure of the current gear.

[0060] In the embodiment of the present invention, the actual slip is the average value of the slip at the oil pressure build-...

Embodiment 2

[0087] Figure 5 A structural diagram of an oil pressure adaptive device based on PI control provided by Embodiment 2 of the present invention.

[0088] In order to realize the oil pressure adaptive method based on PI control in the above embodiment, refer to Figure 5 , an embodiment of the present invention provides a PI control-based oil pressure adaptive device, including:

[0089] The first determination module 11 is used to obtain the actual slip, and determine the slip difference according to the actual slip and the target slip during the oil filling stage;

[0090] The second determination module 12 is used to compare the slip difference with the reasonable range of slip control, and calculate the OG clutch oil pressure compensation amount by using the PI control formula according to the comparison result;

[0091] The third determination module 13 is configured to determine the second OG clutch oil pressure of the next gear according to the oil pressure compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com