Hydraulic transmission structure with buffer structure

A technology of hydraulic transmission and buffer structure, applied in the directions of transmission parts, gear vibration/noise attenuation, belt/chain/gear, etc., can solve problems such as large impact force, limitations of applicability and practicality, mismatch of upper and lower strokes, etc. , to achieve reasonable structural settings, improve the stability and reliability of use, and good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

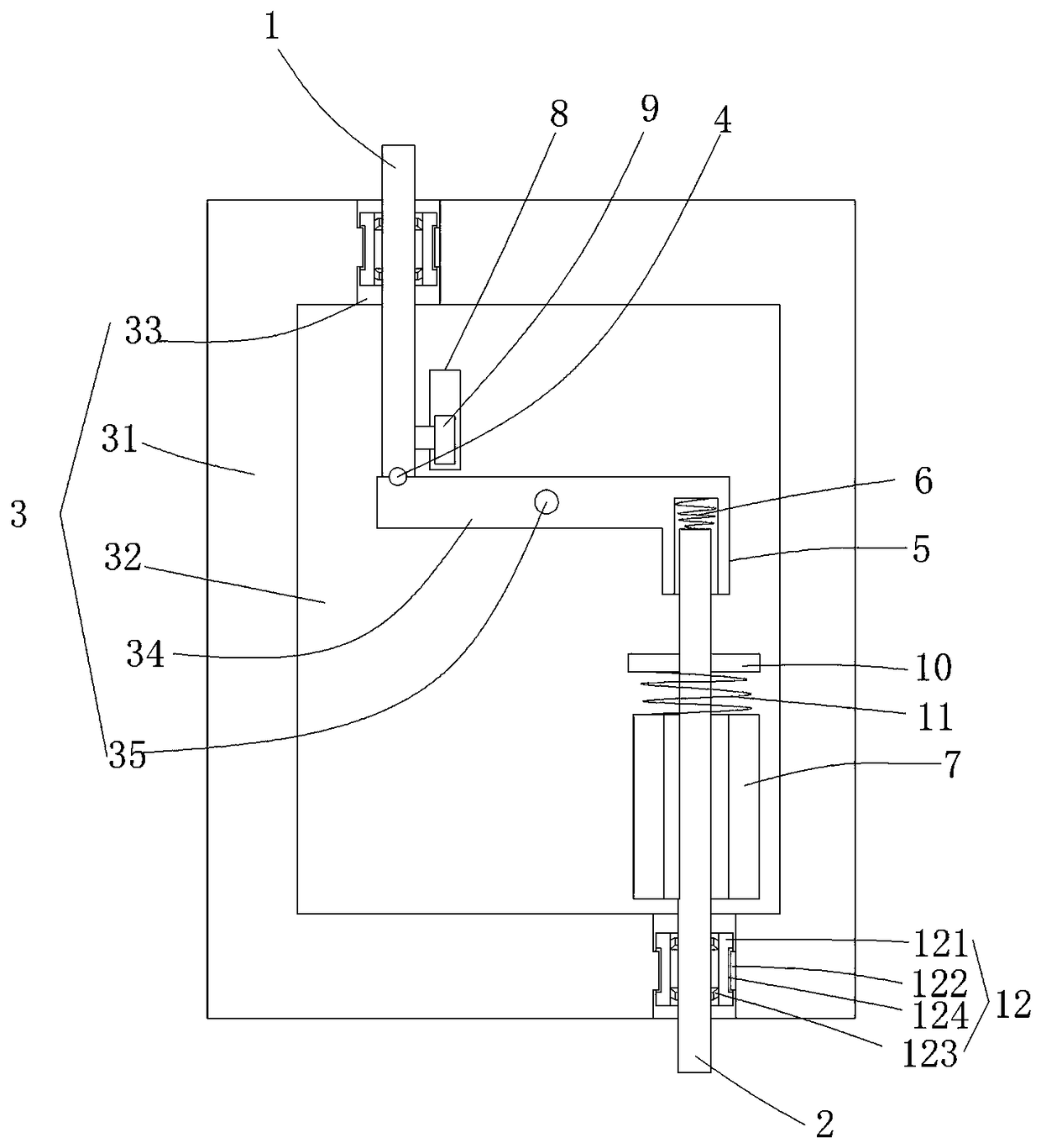

[0015] figure 1 An embodiment of the invention is shown in which figure 1 It is a schematic diagram of the structure of the present invention.

[0016] See figure 1 , a hydraulic transmission structure with a buffer structure, including a first transmission rod 1 and a second transmission rod 2, the first transmission rod is connected with the hydraulic structure, and the first transmission rod and the second transmission rod are A buffer connection structure 3 is arranged therebetween, and the buffer connection structure 3 includes a casing 31, a buffer cavity 32 is arranged in the casing, and the symmetrical side walls of the casing are fixed with the buffer concave The connecting circular hole 33 connected to the cavity is provided with a tilting rod 34 in the buffer cavity, and the middle part of the tilting rod is connected to the center of the buffer cavity through the rotating shaft 35, and the first transmission rod is connected through the connection The circular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com