Lead air drying machine

An air dryer and lead wire technology, used in dryers, progressive dryers, drying and other directions, can solve the problems of low air drying efficiency and high energy consumption, and achieve the effect of ensuring continuous reliability, ensuring drying quality, and fast and efficient drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

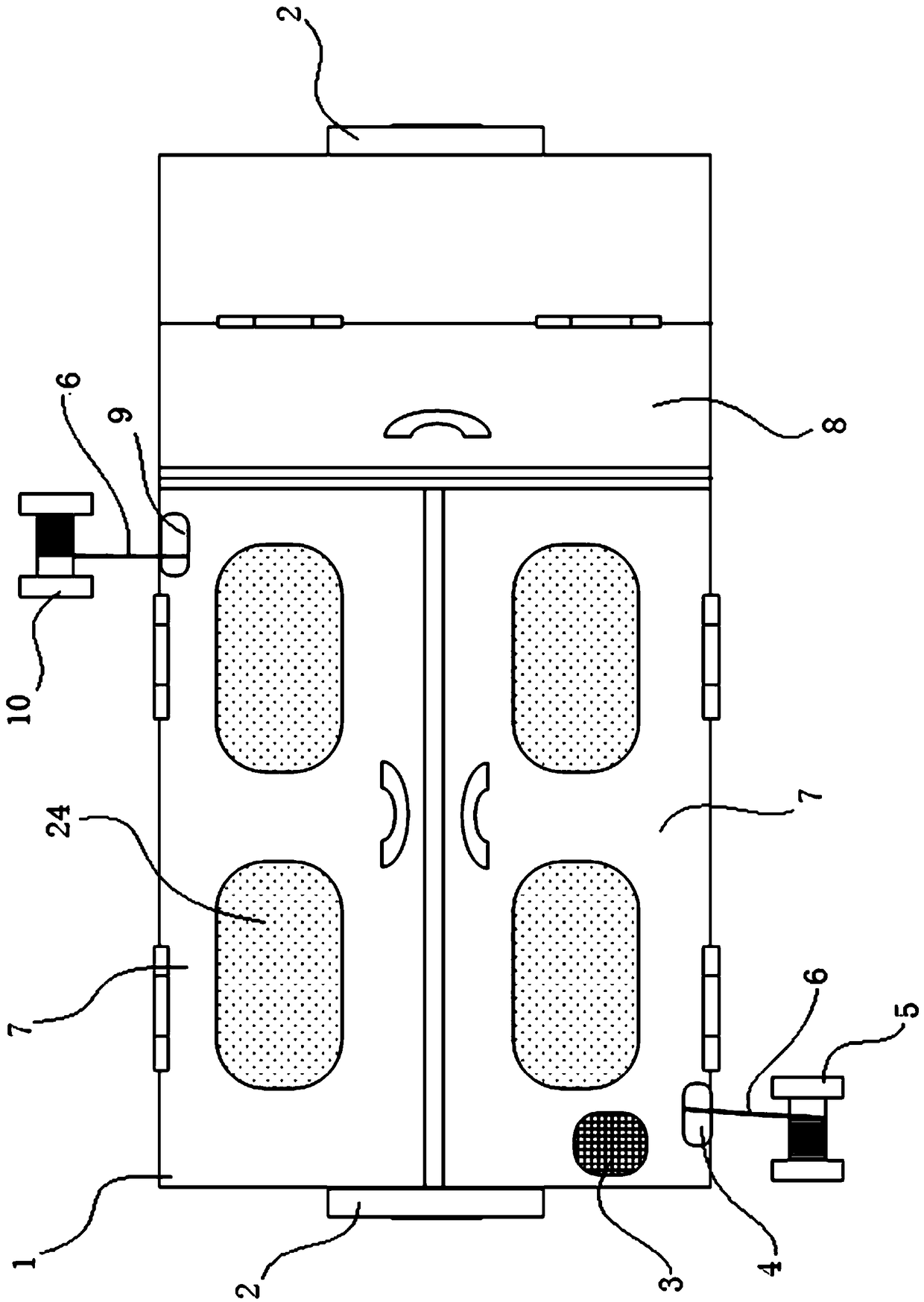

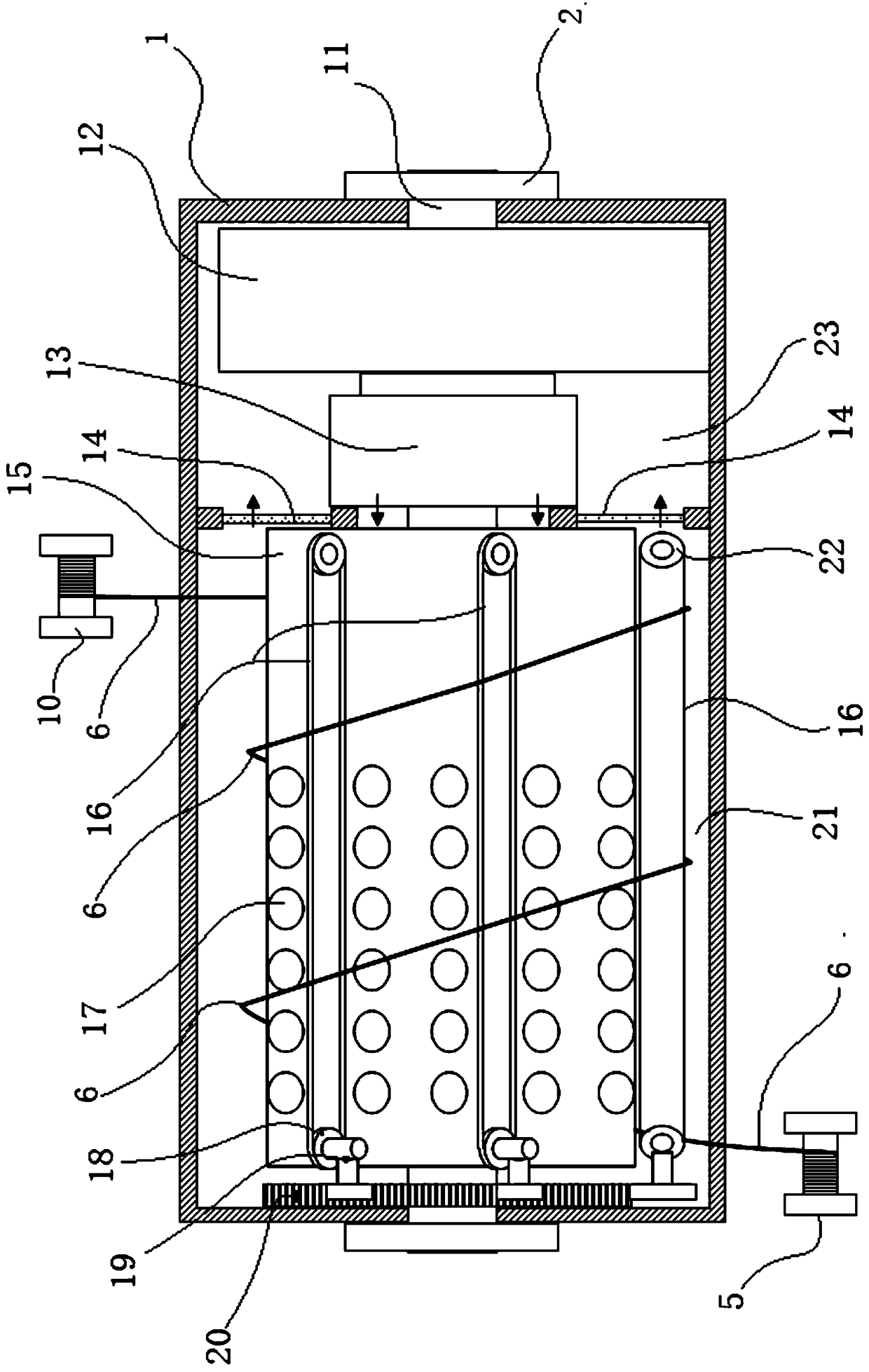

[0013] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the lead wire air dryer includes a drum 15 installed in the box body 1 , and the rotating axis 11 of the drum 15 is installed on both ends of the box body 1 through bearings 2 .

[0014] The drum 15 is provided with a synchronous belt 16, and the synchronous belt 16 circulates around the driving wheel 18 and the driven wheel 22. The direction of the circular rotation is along the direction parallel to the axis of the drum 15, and several synchronous belts 16 are evenly distributed around the circumference of the drum 15. Distribution, drives the lead wire 6 that is wound on the synchronous belt 16 (only draws a lead wire 6 as an example in the figure, and in actual work a plurality of lead wires are wound side by side and are all over the circumferential surface of the whole cylinder 15). The driving wheel 18 is connected to the fixed gear 20 through a bevel gear transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com