Electric retractable type rocket prototype supporting mechanism

A support mechanism and retractable technology, applied in the field of electric retractable retractable rocket prototype support mechanism, can solve the problems of large air resistance of rocket launch, failure of recovery work, small diameter of support circle, etc., to achieve good landing stability, Ensure normal operation and the effect of supporting a large diameter of the circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

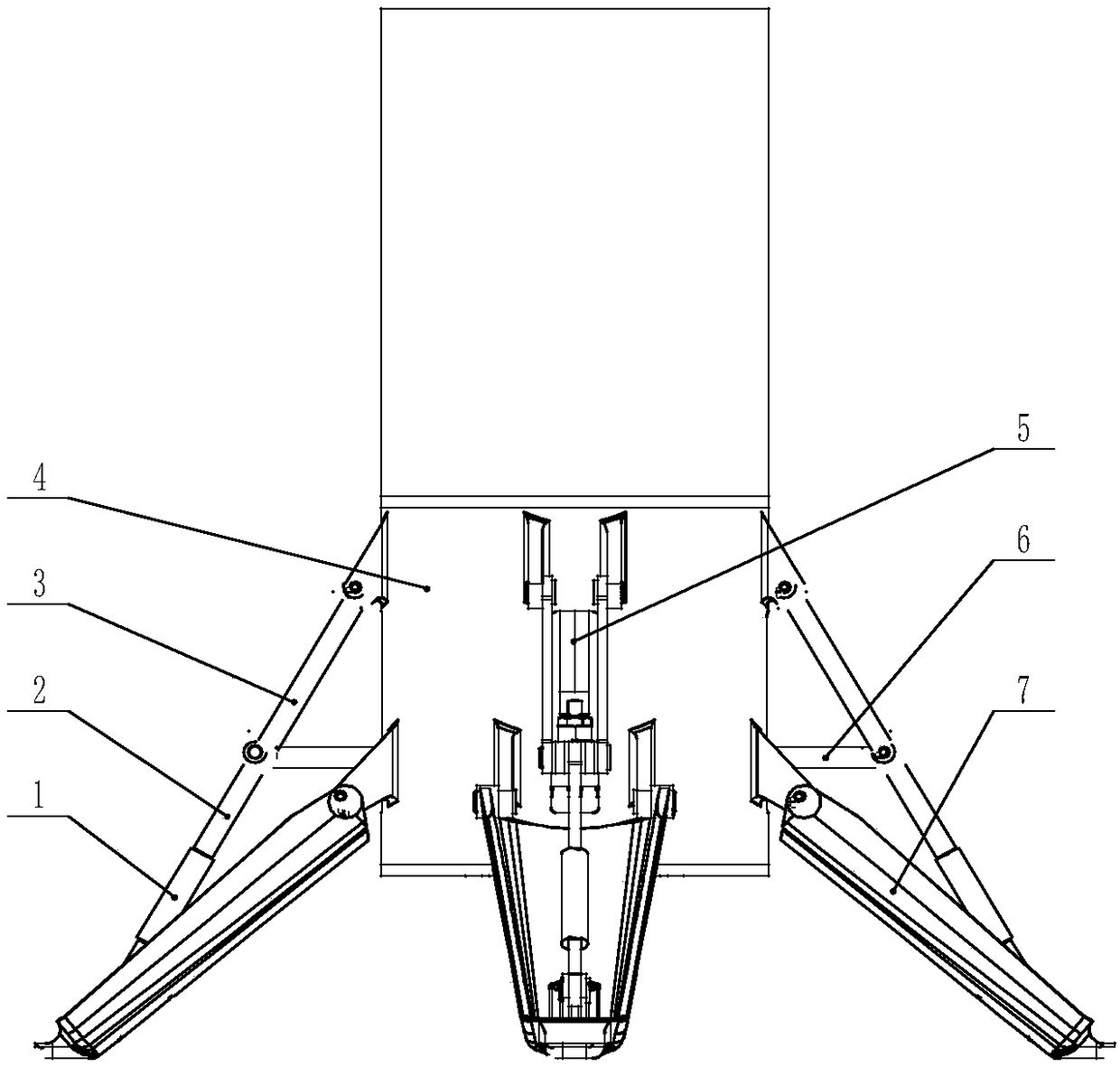

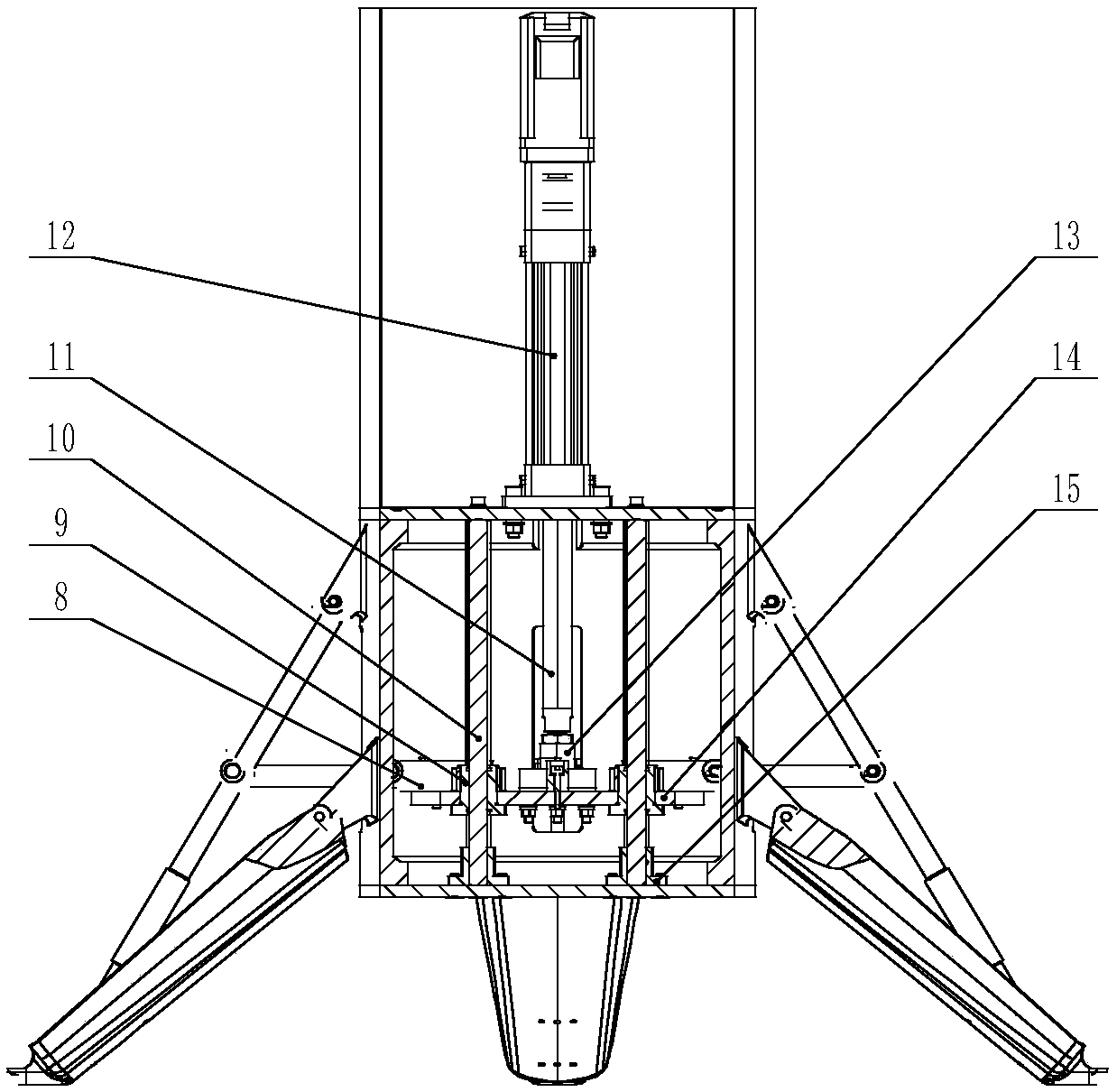

[0011] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, an electric retractable retrievable rocket prototype support mechanism described in this embodiment, it includes a drive assembly 5 and multiple sets of support leg assemblies, each set of support leg assemblies includes a buffer 1, a support leg support link 2. The supporting link 3 of the rocket body, the driving link 6 and the supporting leg 7, the driving assembly 5 is installed inside the bottom of the main body 4, multiple sets of supporting leg assemblies are evenly distributed around the bottom of the main body 4, and the top of the supporting leg 7 rotates Connected and installed on the side wall of the main body 4, the support leg support link 2 is connected with the support leg 7 through the buffer 1, the top end of the support leg support link 2 and the bottom end of the rocket body support link 3 pass through the pin shaft and the drive link One end of 6 is rotatably conn...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 and figure 2 This embodiment will be described. In the electric retractable retrievable rocket prototype support mechanism described in this embodiment, the number of multiple sets of support leg assemblies is four, and the other methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 1-Figure 2 Describe this embodiment, an electric retractable type retrievable rocket prototype support mechanism described in this embodiment, the center line of the buffer 1 on each set of support leg assemblies, the center line of the support leg support link 2, the rocket body support link The centerline of the rod 3, the centerline of the drive link 6 and the centerline of the support leg 7 are located in the same plane. Other methods are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com