A kind of two-for-one twist spinning method

A double-twisting, yarn-feeding technology, applied in spinning machines, continuously wound spinning machines, textiles and papermaking, etc., can solve the problems of large influence of spinning balloon, difficult operation of the mechanism, poor practicability, etc. Eliminate the winding process, improve the twisting efficiency, and avoid the effect of yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

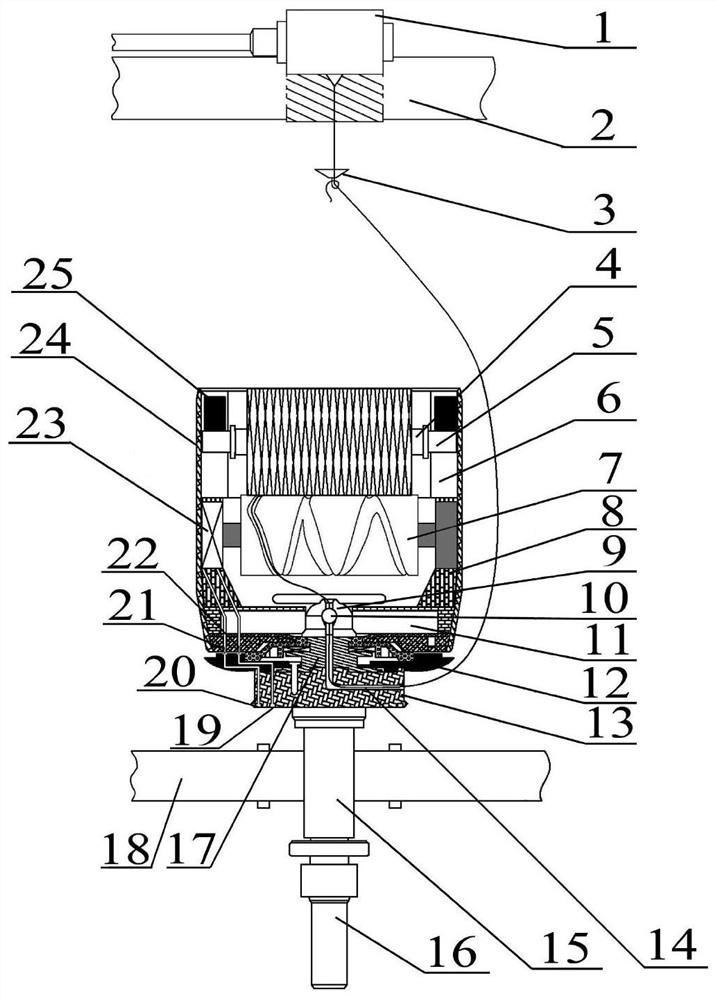

[0010] A two-for-one twist spinning method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] see Attachment.

[0012]A two-for-one twist spinning method, which is composed of rear rollers, rear top rollers, middle upper rollers, middle lower rollers, middle upper aprons, middle lower aprons, upper pins, lower pins, front rollers 2, and front top rollers 1 The front of the spinning frame drafting system is equipped with a two-for-one twisting winding mechanism. The two-for-one twisting and winding mechanism is composed of a two-for-one twisting mechanism and a winding mechanism. , yarn feeding pipe 14, spindle disk 12, rotor assembly 17, stationary disk, yarn storage tank 24, inner magnetic steel 11, positioning sleeve 9, tensioner 10, and yarn output tube. The lower end of the spindle rod 15 is movably inserted into the spindle seat 16, and the rod body of the spindle rod 15 is closely attached to the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com