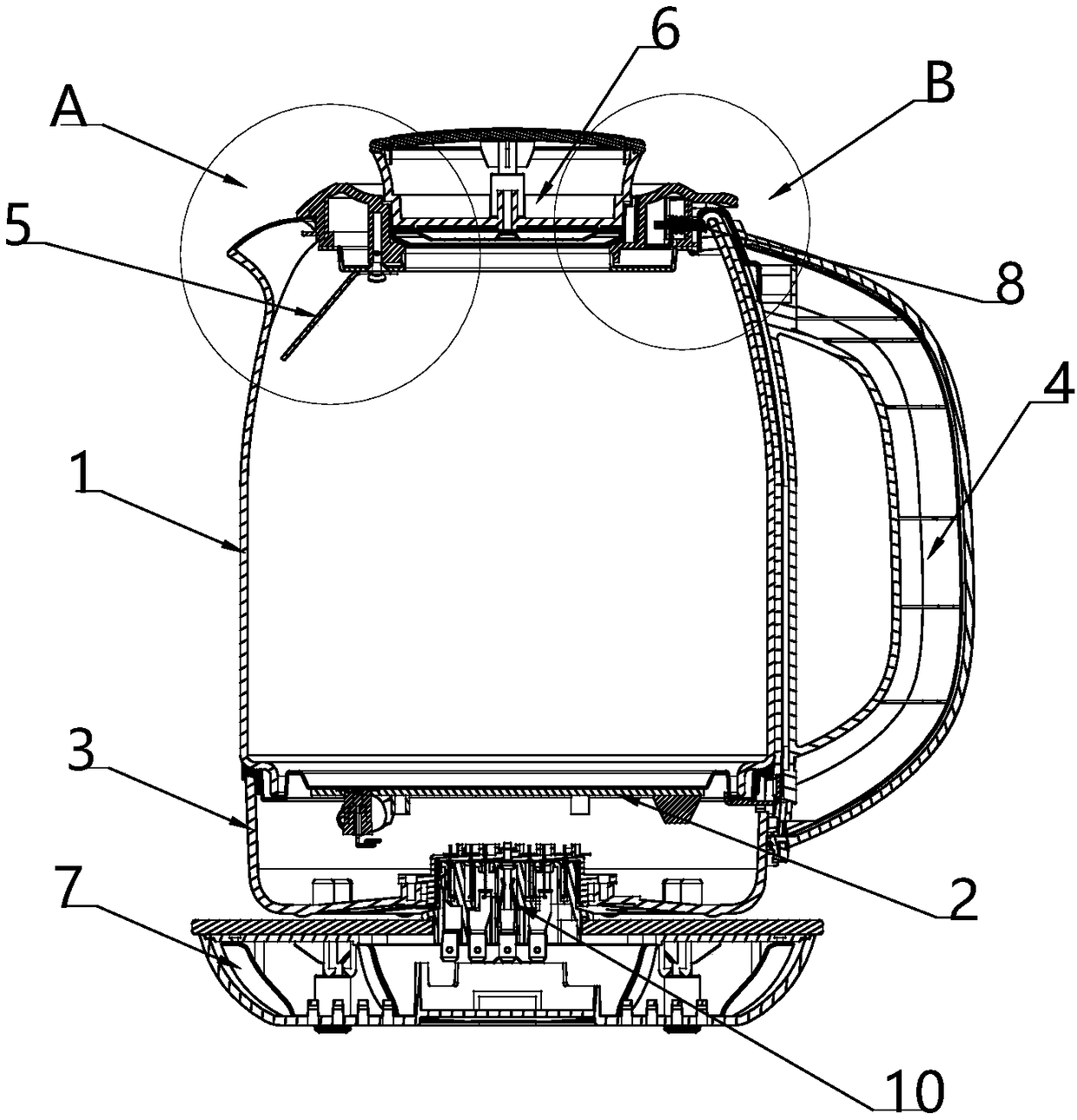

Electric kettle

An electric kettle and lid technology, which is applied to water boiling utensils, overflow prevention, cooking utensils, etc., can solve the problems of small contact surface of air bubbles, increased foam, overflowing outside the kettle, etc., so as to prevent splashes and increase detection. area, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

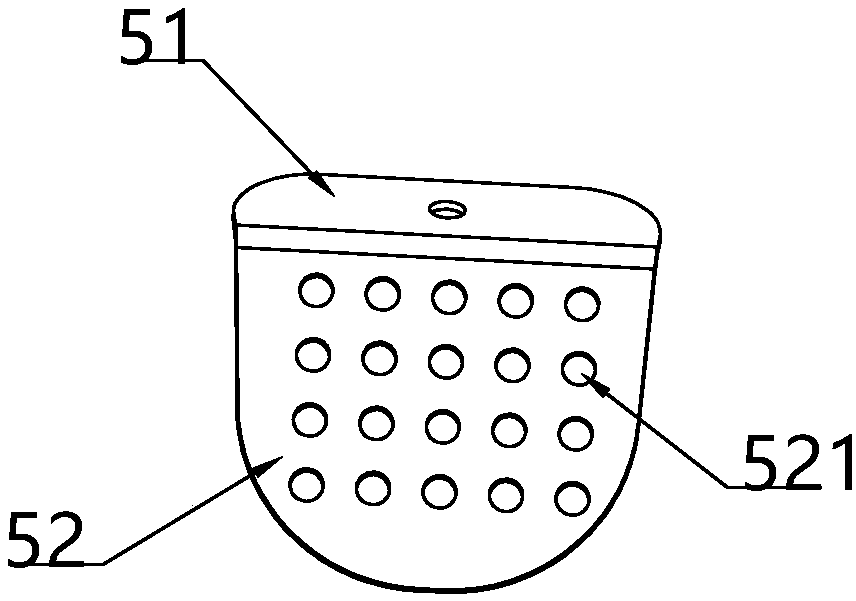

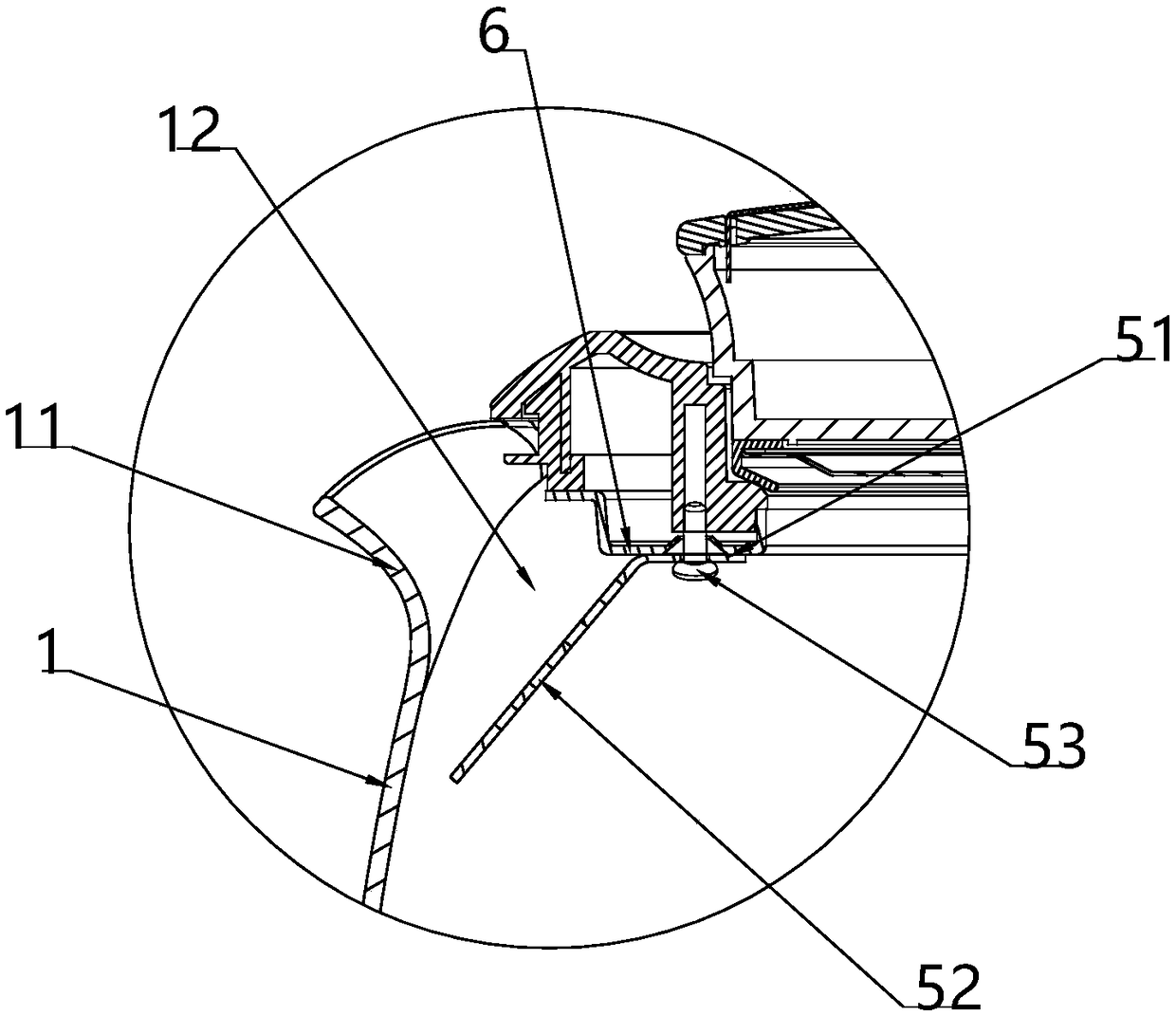

[0059] Based on the structure of Embodiment 1, when the pot cover 6 includes an upper cover 61 and a lower cover 62, and an accommodation chamber is formed between the upper cover 61 and the lower cover 62, the pot cover 6 and the overflow-proof electrode sheet 5, the second The installation scheme of a component 8 will be described in detail below in conjunction with the accompanying drawings in the present invention. The ways in which the anti-overflow electrode sheet 5 is connected with the kettle lid 6 are as follows:

[0060] The first type, such as image 3 As shown, the connection portion 51 of the anti-overflow electrode sheet 5 is located below the lower cover 62, and the anti-overflow electrode sheet 5 is connected to the lower cover 62 through a first fastener 53, the first The fastener 53 may be a structure such as a screw, a nut, or a bolt.

[0061] In the second type, the connecting portion 51 of the anti-overflow electrode sheet 5 is located between the upper ...

Embodiment 3

[0067] Based on the structure of embodiment 1 or 2, the mode that the first part 8 is connected with the pot lid 6 has the following several kinds:

[0068] First, the first component 8 is located between the upper cover 61 and the lower cover 62 , and the first component 8 can be connected to the upper cover 61 . For specific structural forms, reference may be made to the description below.

[0069]In order to ensure that the electrode signal can be stably transmitted to the control board, the first part 8 is elastically arranged on the pot cover 6, the first part 8 can slide in the pot cover 6, and the pot cover 6 is closed on the When the liner is put on, the first part 8 retracts into the pot lid 6 , and the first part 8 is in close contact with the second part 43 . That is, when the pot lid 6 is not installed, the length of the first component 8 protruding from the pot lid 6 is greater than the width of the pot lid 6 from the second component 43 . The above-mentioned fi...

Embodiment 4

[0077] Based on the structure of Embodiment 1 or 2 or 3, the second component 43 and the installation structure of the second component 43 on the handle 4 will be described in detail below.

[0078] like Figure 8 , Figure 9 As shown, the second part 43 is a sheet metal piece, one end of the metal piece is bent to form a first hooking part 431, and the first hooking part 431 is hooked at the spout of the inner container The part of the first hooking part 431 located in the inner container is in contact with the first component 8 (such as the above-mentioned conductive contact rod 81), and the other end of the metal part is electrically connected with the control board.

[0079] Further, the other end of the metal piece is connected to the handle 4 . At this time, the metal piece can also play the role of fixing the upper end of the handle 4 .

[0080] Further, the other end of the metal part is located between the outer wall of the inner container and the handle 4, and als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com